Get Tech Tips

Subscribe to free tech tips.

Fan (Blower) Efficacy

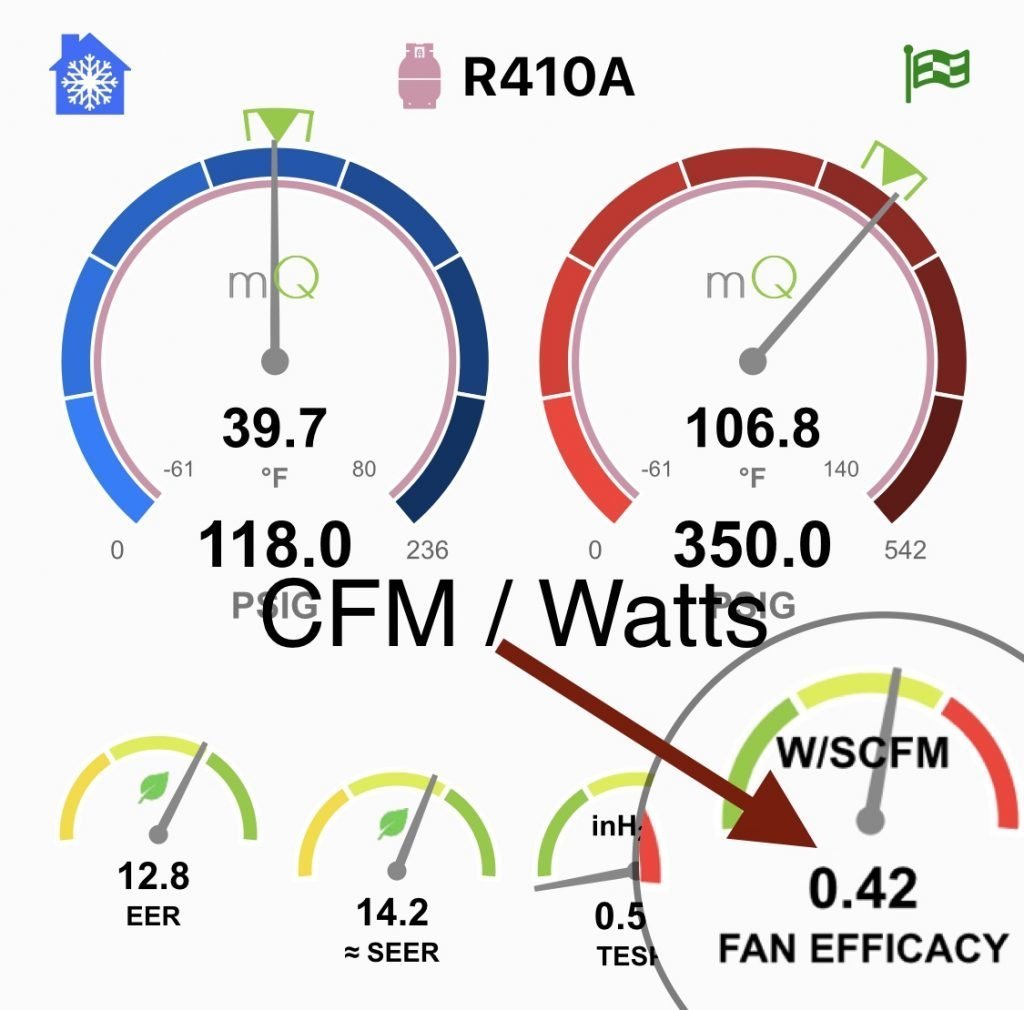

For those of you who use the MeasureQuick app for system diagnosis and performance testing, you may have noticed the “fan efficacy” results and wondered what it is.

It is simply the CFM output of the system divided by the wattage used by the blower. It is only for the blower motor and has nothing to do with the other components when done properly.

Fan (blower) efficacy is called out in various codes and standards, such as the California Energy Commissions' requirement that all blowers perform at or below a 0.58 fan efficacy. That means a blower that is moving 1000 CFM cannot use more than 580 watts of power to do so.

CFM

The tricky part of measuring fan efficacy is getting accurate measurements of system CFM and blower amperage. We can use equipment manufacturer fan charts and an accurate TESP (total external static pressure) measurement to figure out the CFM when the system is new and clean. When using these charts, it's important that the system is set up and runs according to what is shown on the chart; one wrong pin setting or input can lead to vastly different airflow than the chart shows, resulting in a fan efficacy value that is way off.

Other options like measuring airflow at the return with a hood, anemometer duct traverse, or the Trueflow from TEC can be used for measuring system CFM, but all have their own challenges.

Blower Wattage

When measuring blower amperage, the panels must be in place, which can be difficult to accomplish on some system types, making a wireless connected ammeter very handy where the meter can be put in place and the panels put back on for testing.

Traditionally, techs calculate wattage by measuring voltage and amperage and multiplying them together. That is actually VA—not wattage— because it does not account for the power factor. The only way to measure wattage accurately is to use a watt or power quality meter, like the Redfish IDVM550, which calculates wattage by multiplying the VA by the power factor for the final wattage.

ECM Motors

ECM (electronically commutated motor) motors are more efficient than traditional PSC motors, but their efficacy will generally vary based on the static pressure they are subjected to. Because most ECM motors are either constant airflow or constant torque rather than constant speed, they will increase in wattage as the static pressure increases. That means that the fan efficacy will decrease on these motors as filters and coils become dirtier.

—Bryan

Comments

To leave a comment, you need to log in.

Log In