Get Tech Tips

Subscribe to free tech tips.

How (and Why) to Flow Nitrogen While Brazing

When I started in the trade, the idea of flowing nitrogen while brazing was nothing more than the punchline of a joke. Like pulling a vacuum with a micron gauge or proper recovery, it was a wink and nod proposition rather than a real practice. I've had to unlearn many bad habits since those early days, and the practice of flowing nitrogen while brazing is one that I still hear being mocked as “overkill” by old-timers. It isn't hard, it isn't overkill, and it makes a BIG difference. If you just keep reading instead of rolling your eyes, I will tell you the reasons why.

What Flowing Nitrogen Accomplishes

Copper and oxygen react to create “cupric oxide,” or copper oxide, similar to how iron and oxygen react to create rust. When we heat copper over about 500°, this begins to occur rapidly. As heat and oxygen increase, you'll see more copper oxide scale building up. We see this occur all the time on the OUTSIDE of the copper, where oxygen is prevalent in the air, though this can also occur inside the copper if there is air inside the system rather than dry nitrogen. It's made worse when the joint is hotter and when you leave the copper open to the air for longer periods while working. When we prevent air from entering the lines in the first place by keeping them sealed as much as possible and THEN flow nitrogen while brazing, we can prevent copper oxide from forming—this practice keeps line filter/driers, screens, compressor oil, and valves (ever heard of a bad TXV?) free from contamination and prevents many issues. Not to mention, it ALSO helps speed up the evacuation process.

Why Old-Timers Say it Doesn't Matter

Many techs who have done this work for a long time haven't flowed nitrogen EVER and have gotten away with it because of mineral oil. Older CFC and HCFC refrigerants used mineral oil rather than POE/PVE or PAG oils that we see today, which have higher solvent properties that “scrub” the oxide from the walls and deposit it into driers and screens. Techs in the grocery industry know that when a system is converted from mineral or AB oil over to POE, it is very common for this cupric scale to clog screens pretty quickly after the changeover. The point here is that mineral oil was forgiving on small amounts of cupric oxide on the tubing walls, but POE isn't.

The Process

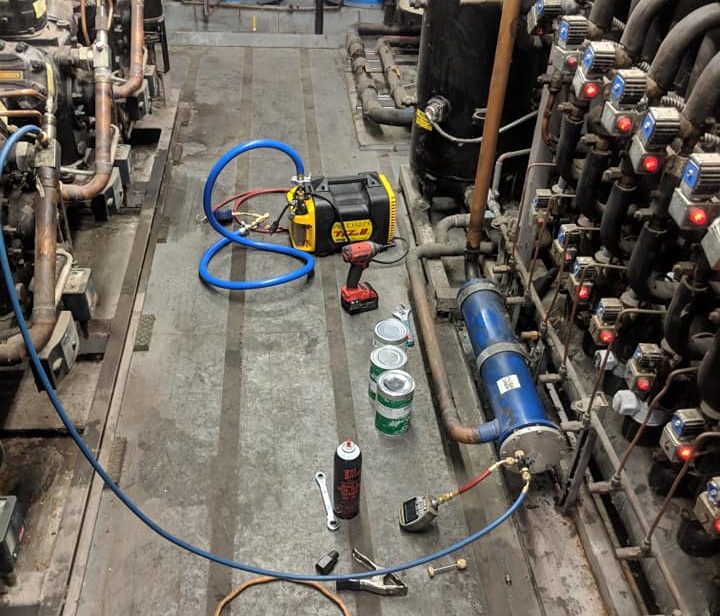

Keeping copper oxide out of the system is really quite easy with a common-sense approach in place, starting with just pulling the nitrogen tank and flow regulator off of the truck, along with the torches, FIRST THING. There are several great flow regulators on the market—a few built right into the regulator and some that you attach to the outlet of the regulator. Keep in mind that you need to FLOW nitrogen, not PRESSURIZE with nitrogen while brazing. Otherwise, you never get the joints to hold.

- REMOVE CORES – When you set up, you first need to remove your cores in the inlet and outlet of the brazing path so that you can get full flow with minimum backpressure.

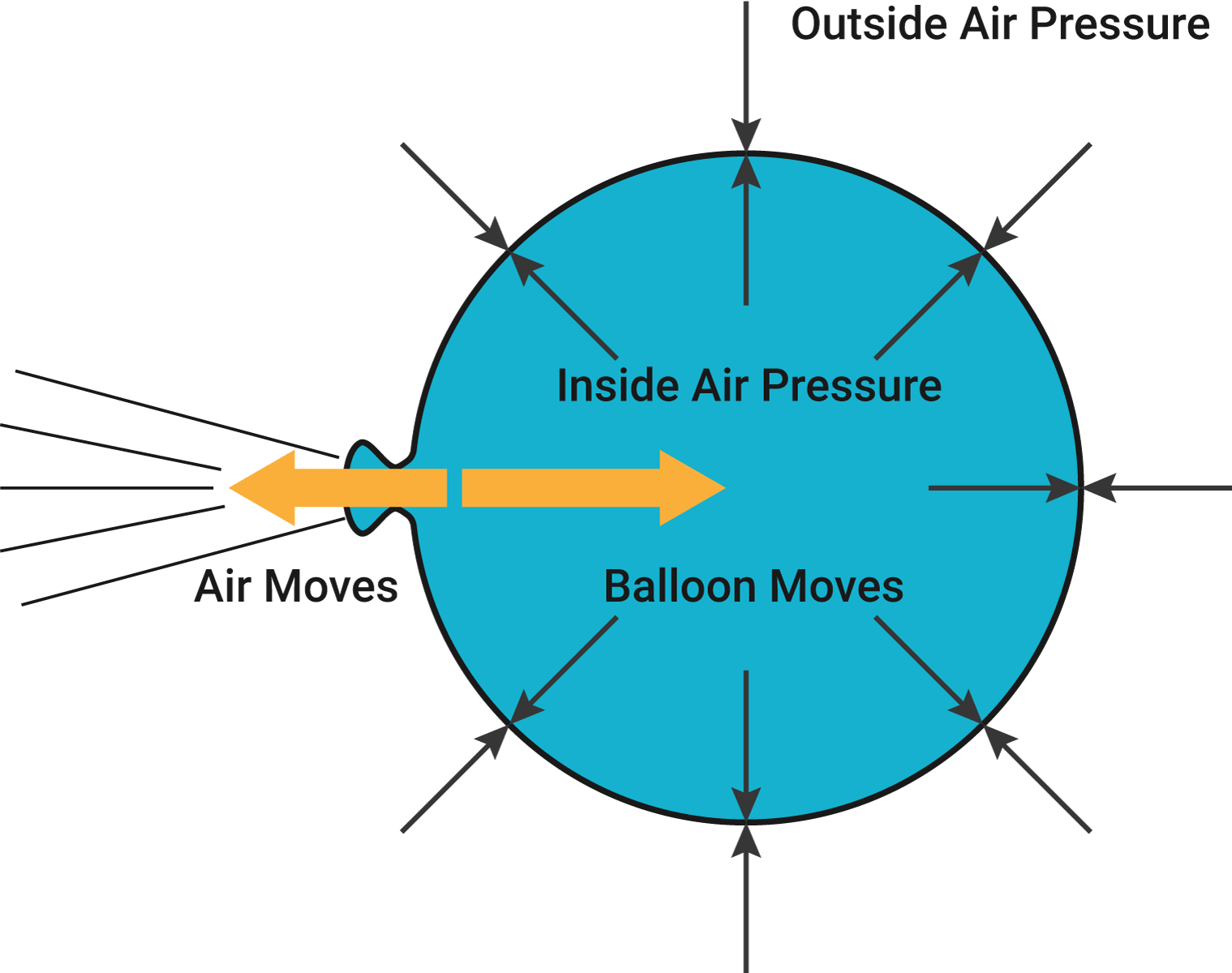

- PURGE OUT AIR – Purge nitrogen at fairly high pressure in the direction of the refrigerant flow to help “chase” the air out of the circuit and fill it with nitrogen.

- FLOW WITH 2-5 SCFH – Flow with a VERY LOW flow of 2-5 standard cubic feet per hour of flow, which is just a whisper out the end.

- DON'T FREAK OUT – The very last joint can be tough on small systems. It's OK if you shut off the flow or reduce it down to next to nothing for that last joint. Don't make being “perfect” the enemy of getting started flowing nitrogen while brazing. Don't overthink it, and stop making excuses for not doing it.

If you follow this process and then pressure test with nitrogen before evacuation, it will go much more smoothly. All in all, it can save you time in the process. Nitrogen is cheaper than callbacks and early component failure. Use it.

If you need any more convincing or simply want to learn more about flowing nitrogen, give this article a read or watch this video.

—Bryan

Comments

I have a comment about switching from R22 to R410A (see ” Why Old-Timers Say It Doesn’t Matter.”)

The R22 system using mineral oil could have slug deposited on the copper pipe walls from mineral oil degradation due to time and heat. This slug can cover the copper oxide particles and the R22 system continues to run as usual without the oxide flaking off. However, when the R410A with POE is added, the slug is cut lose with or without the copper oxide ‘flakes’. Then, there is a nasty blackish slug noticed in the filter! The assumption in the article is that the POE cut the copper oxide loose. Wouldn’t it be more correct to say that the POE oil cuts the slug ana hence the oxide is exposed and then carried away. Does anyone have any data to support the statement that the copper oxide is cut loose? Has anyone identified the oxide in the filters or screens?

I have a comment about switching from R22 to R410A (see ” Why Old-Timers Say It Doesn’t Matter.”)

The R22 system using mineral oil could have slug deposited on the copper pipe walls from mineral oil degradation due to time and heat. This slug can cover the copper oxide particles and the R22 system continues to run as usual without the oxide flaking off. However, when the R410A with POE is added, the slug is cut lose with or without the copper oxide ‘flakes’. Then, there is a nasty blackish slug noticed in the filter! The assumption in the article is that the POE cut the copper oxide loose. Wouldn’t it be more correct to say that the POE oil cuts the slug ana hence the oxide is exposed and then carried away. Does anyone have any data to support the statement that the copper oxide is cut loose? Has anyone identified the oxide in the filters or screens?

Хотите найти данные о человеке ? Этот бот поможет полный профиль мгновенно.

Воспользуйтесь уникальные алгоритмы для анализа публичных записей в открытых источниках.

Узнайте контактные данные или активность через автоматизированный скан с верификацией результатов.

глаз бога телеграм

Бот работает в рамках закона , используя только открытые данные .

Получите расширенный отчет с геолокационными метками и графиками активности .

Попробуйте надежному помощнику для digital-расследований — точность гарантирована!

Хотите найти данные о человеке ? Этот бот поможет полный профиль мгновенно.

Воспользуйтесь уникальные алгоритмы для анализа публичных записей в открытых источниках.

Узнайте контактные данные или активность через автоматизированный скан с верификацией результатов.

глаз бога телеграм

Бот работает в рамках закона , используя только открытые данные .

Получите расширенный отчет с геолокационными метками и графиками активности .

Попробуйте надежному помощнику для digital-расследований — точность гарантирована!

Нужно собрать данные о человеке ? Наш сервис предоставит детальный отчет мгновенно.

Используйте уникальные алгоритмы для анализа цифровых следов в соцсетях .

Выясните контактные данные или активность через автоматизированный скан с верификацией результатов.

зеркало глаз бога

Бот работает в рамках закона , обрабатывая общедоступную информацию.

Получите расширенный отчет с геолокационными метками и списком связей.

Доверьтесь проверенному решению для исследований — результаты вас удивят !

Нужно собрать данные о человеке ? Наш сервис предоставит детальный отчет мгновенно.

Используйте уникальные алгоритмы для анализа цифровых следов в соцсетях .

Выясните контактные данные или активность через автоматизированный скан с верификацией результатов.

зеркало глаз бога

Бот работает в рамках закона , обрабатывая общедоступную информацию.

Получите расширенный отчет с геолокационными метками и списком связей.

Доверьтесь проверенному решению для исследований — результаты вас удивят !

Хотите найти информацию о пользователе? Этот бот предоставит детальный отчет в режиме реального времени .

Используйте продвинутые инструменты для анализа цифровых следов в открытых источниках.

Выясните место работы или интересы через систему мониторинга с верификацией результатов.

глаз бога проверить

Бот работает с соблюдением GDPR, используя только общедоступную информацию.

Закажите расширенный отчет с геолокационными метками и списком связей.

Попробуйте проверенному решению для исследований — результаты вас удивят !

Хотите найти информацию о пользователе? Этот бот предоставит детальный отчет в режиме реального времени .

Используйте продвинутые инструменты для анализа цифровых следов в открытых источниках.

Выясните место работы или интересы через систему мониторинга с верификацией результатов.

глаз бога проверить

Бот работает с соблюдением GDPR, используя только общедоступную информацию.

Закажите расширенный отчет с геолокационными метками и списком связей.

Попробуйте проверенному решению для исследований — результаты вас удивят !

Discover the iconic Patek Philippe Nautilus, a horological masterpiece that merges sporty elegance with exquisite craftsmanship .

Introduced nearly 50 years ago, this cult design revolutionized high-end sports watches, featuring signature angular cases and textured sunburst faces.

From stainless steel models like the 5990/1A-011 with a 55-hour energy retention to luxurious white gold editions such as the 5811/1G-001 with a blue gradient dial , the Nautilus caters to both avid enthusiasts and everyday wearers .

New Patek Philippe Nautilus 5980r information

The diamond-set 5719 elevate the design with dazzling bezels , adding unmatched glamour to the timeless profile.

According to recent indices like the 5726/1A-014 at ~$106,000, the Nautilus remains a prized asset in the world of premium watchmaking.

For those pursuing a vintage piece or contemporary iteration , the Nautilus epitomizes Patek Philippe’s legacy of excellence .

Discover the iconic Patek Philippe Nautilus, a horological masterpiece that merges sporty elegance with exquisite craftsmanship .

Introduced nearly 50 years ago, this cult design revolutionized high-end sports watches, featuring signature angular cases and textured sunburst faces.

From stainless steel models like the 5990/1A-011 with a 55-hour energy retention to luxurious white gold editions such as the 5811/1G-001 with a blue gradient dial , the Nautilus caters to both avid enthusiasts and everyday wearers .

New Patek Philippe Nautilus 5980r information

The diamond-set 5719 elevate the design with dazzling bezels , adding unmatched glamour to the timeless profile.

According to recent indices like the 5726/1A-014 at ~$106,000, the Nautilus remains a prized asset in the world of premium watchmaking.

For those pursuing a vintage piece or contemporary iteration , the Nautilus epitomizes Patek Philippe’s legacy of excellence .

An impressive share! I have just forwarded this onto a colleague who has been conducting a little research on this. And he actually bought me lunch simply because I found it for him… lol. So allow me to reword this…. Thanks for the meal!! But yeah, thanx for spending time to discuss this topic here on your web page.

An impressive share! I have just forwarded this onto a colleague who has been conducting a little research on this. And he actually bought me lunch simply because I found it for him… lol. So allow me to reword this…. Thanks for the meal!! But yeah, thanx for spending time to discuss this topic here on your web page.

This online store offers a large assortment of stylish wall-mounted clocks for all styles.

You can discover contemporary and traditional styles to enhance your living space.

Each piece is chosen for its craftsmanship and functionality.

Whether you’re decorating a stylish living room, there’s always a fitting clock waiting for you.

best birdhouse pendulum wall clocks

The shop is regularly expanded with exclusive releases.

We ensure quality packaging, so your order is always in good care.

Start your journey to enhanced interiors with just a few clicks.

This online store offers a large assortment of stylish wall-mounted clocks for all styles.

You can discover contemporary and traditional styles to enhance your living space.

Each piece is chosen for its craftsmanship and functionality.

Whether you’re decorating a stylish living room, there’s always a fitting clock waiting for you.

best birdhouse pendulum wall clocks

The shop is regularly expanded with exclusive releases.

We ensure quality packaging, so your order is always in good care.

Start your journey to enhanced interiors with just a few clicks.

To leave a comment, you need to log in.

Log In