BACK

Charging Systems with Accumulators

Charging Systems with Accumulators

Accumulator & Burnout Considerations

Accumulator & Burnout Considerations

What is a Suction Accumulator?

What is a Suction Accumulator?

Diagnosing & Replacing a Compressor

Diagnosing & Replacing a Compressor

#accumulator

Tech Tips:

In air conditioning service, we don't always see systems with accumulators. In fact, they are pretty uncommon unless you work on a lot of heat pumps. However, as heat pumps gain popularity, charging systems with accumulators will be a good skill to have in your tool bag. We are Carrier dealers in Florida, so we […]

Read more

The suction line accumulator is designed to keep liquid refrigerant from entering the compressor while still allowing for oil return. The trouble is that if the oil return port/screen clogs, the accumulator can fill with oil and actually cause the compressor to fail. In addition to that, it can hold contaminated oil in a burnout. […]

Read more

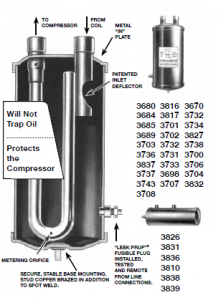

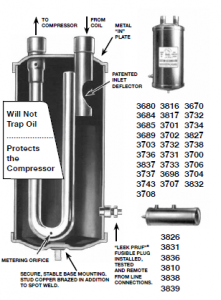

Suction Accumulators A suction accumulator is used to prevent liquid refrigerant floodback to the compressor. A compressor is designed to move vapor refrigerant, NOT liquid, and the accumulator can really help us win that battle. Accumulators are commonly used on heat pumps, transportation refrigeration systems, low-temp supermarket systems, and any place where liquid refrigerant flooding […]

Read morePodcasts:

In this podcast episode, Bryan goes over best practices for diagnosing and replacing an A/C or refrigeration compressor. When testing for a shorted compressor, make sure the compressor is isolated from all of its circuitry. You would see low ohms to ground in a shorted compressor. Do NOT measure from winding to winding or terminal […]

Read more