BACK

A Liquid Line Solenoid and What it Does

A Liquid Line Solenoid and What it Does

Solenoid Facts

Solenoid Facts

#Solenoid

Tech Tips:

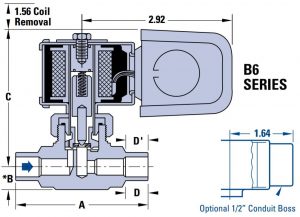

Depending on what segment of the business you are in and your location, you either work on pump down solenoid systems all the time, or YOU HAVE NO CLUE what they are. A liquid line solenoid is just a valve that opens and closes; it has a magnetic coil. Depending on whether the valve is […]

Read more

Do you know how a solenoid valve works? Really? On the surface, I think we all understand how a solenoid valve works. The coil energizes, creating an electromagnet. That temporary magnetism lifts an iron plunger within the valve allowing refrigerant to flow. But is it really that simple? It turns out that the answer isn't […]

Read more