Get Tech Tips

Subscribe to free tech tips.

Traditional & Desiccant Dehumidification and When to Use Each (or Both)

This tech tip about traditional and desiccant dehumidification is based on a conversation with Nikki Krueger and David Schurk. Nikki is a longtime contributor to HVAC School and is a relatively frequent podcast guest and symposium speaker. David Schurk is the Director of Applied Engineering and National Sales Manager at Innovative Air Technologies. Nikki specializes in traditional cold-coil dehumidifiers, and David specializes in solid desiccant dehumidification.

We talk about dehumidification a lot on here because there is a HUGE need for it in our Southeastern market. However, climate data has trended warmer and wetter in multiple areas of the country, so the dehumidification discussion is crucial for most of the USA. On top of that, building codes have changed, and we’re building tighter and tighter buildings with fresh air requirements, so we need more controlled pathways for air to come in without dumping lots of moisture inside.

That’s all to say that dehumidification is important! There’s also more than one way to remove moisture from a space, but we need to make sure we use the right dehumidification technology for the application. We’ll be taking a closer look at traditional cold-coil and solid desiccant dehumidification, including their uses, limitations, and applications. We’ll also cover some possible uses for these technologies to work together.

Moisture/Humidity Basics

Humidity refers to the water vapor content in the air. A very simple way to think of moisture in the air is to imagine the air as a sponge that can hold moisture. That sponge either compresses when the temperature drops or expands when it rises. A larger sponge can hold more moisture without dripping, just like warmer air can hold more moisture.

The measure of how much humidity the air has compared to how much it can hold is the relative humidity (RH), and it’s a percentage. If the air is 85% full of moisture, its RH is 85%. At 100% RH, the air is fully saturated and can’t “hold” any more water vapor; moisture has to come out. Colder air reaches 100% RH more quickly because it can’t hold that much moisture, so any excess moisture condenses on surfaces.

Dew Point

The dew point is the temperature to which air must be cooled to reach 100% RH—or the temperature at which water vapor will be fully saturated and any further cooling will result in condensation.

In coastal areas of Florida, these dew points can be in the mid-70s on average, which means that indoor temperatures can overlap with the dew point and cause sweating. (It’s not just Florida, though; one of the highest dew points ever recorded in the continental US, 88°F, was recorded in Moorhead, MN. That’s right—not Florida or Louisiana—Minnesota.)

When the indoor space is near the dew point (and has surfaces below the dew point), moisture can condense on surfaces we really don’t want it to condense on. That’s a problem for houses with decorative wood paneling or musical instruments. Preventing property damage is just one reason to focus on dehumidification, though.

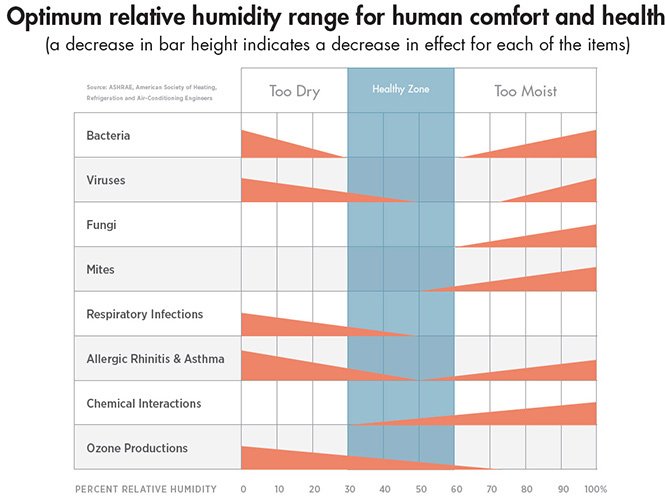

The other important reason is to manage indoor health and safety. There is no perfect environment where we guarantee absolutely no microbial growth, dust mites, or VOCs, but there is a recommended RH range where those things are all least likely to cause trouble: 30–60%. We want to be able to maintain 30–60% RH indoors for health and safety reasons, though it’s worth noting that not all RH readings are created equal.

The Pitfalls of Relying on RH and Not Dew Point

Based on that chart above, you’d think that aiming for 30–60% relative humidity indoors would be the right thing to do. So, can’t we just bring in more 60% RH air from outside to meet ventilation standards? That should still theoretically maintain a perfect indoor environment, right?

Not quite.

What might be 60% RH at one temperature could be 100% RH at another. If it’s 75°F inside, it could be 90°F or higher outside. The amount of moisture in 90°F outdoor air at 60% RH is way more than what’s in 75°F indoor air at 60% RH. If you use a psychrometric chart or dew point calculator, you’d see that the outdoor dew point is 74°F. The air we’d dump into the room would be 97% RH indoors!

That’s why we need to know the target dry-bulb temperature, relative humidity, and dew point to handle a building’s latent load accurately. Many homeowners and facilities managers may not know the dew point, but they can tell you the dry-bulb temperature and relative humidity they want to maintain. These three things can tell us the latent load (in BTUs per hour) we’re trying to match with a dehumidifier.

As an example, Manual J sets these targets at 75°F dry-bulb and 50% RH, which leaves us with a target dew point of around 55°F. However, there are other targets (like the DOE’s 73°F dry-bulb and 60% RH for a ~58°F dew point), and some homeowners or facility managers may have more specific needs. Regardless of the actual targets, RH alone can’t paint that picture without at least a dry-bulb temperature to allow us to figure out the dew point target. (If you’re interested in more information about dehumidifier sizing, Tim De Stasio wrote a tech tip about it.)

So, now that we know to be conscious of the dew point, how can we manage indoor humidity?

HVAC Equipment

While your HVAC equipment can remove some indoor humidity, that’s not its main function. When the system runs, the refrigerant in the evaporator coil absorbs heat. The heat being removed from the airstream is called sensible heat. However, as the system runs a while and the coil gets colder from cool refrigerant flowing through it, the cold surface pulls moisture out of the air. The moisture condenses on the coil and drains out. That’s latent heat removal.

Keep in mind that many of the current efficiency targets are based on sensible heat only. As manufacturers have chased these targets, latent heat and dehumidification haven’t been the focus. You’ll come across systems that are great for getting a space down to the right temperature without using too much power, but they’re not good at dehumidification.

There’s also the oversizing problem. Oversized systems have shorter runtimes because they can cool a space a lot faster. Thermostats only decide to run the HVAC by dry-bulb temperature, not humidity or dew point, so the HVAC systems can’t run long enough for the coil to get cold enough to pull moisture out of the air.

Cold-Coil Dehumidification

Traditionally, we’ve relied on “cold-coil” technology for supplementary dehumidification in residential applications. Standalone and whole-home dehumidifiers have a cold coil filled with refrigerant that pulls moisture out of the air, and then the air is reheated over a warmer coil and ejected. (In the case of a whole-home dehumidifier, it often ties into the central HVAC supply ductwork. The return air usually comes either from the HVAC return or a dedicated return. Ventilating dehumidifiers also have an outdoor air intake for fresh air.)

These systems are like HVAC systems packed into a single box. The cold coil is the evaporator, but these evaporators aren’t designed with sensible heat removal as the main purpose. Like HVAC evaporator coils, dehumidifiers have a cold coil that runs even lower temperatures than HVAC evaporator coils to remove even more latent heat. After the air passes over the evaporator coil, it goes over a hot condenser coil that reheats the air, which further reduces its relative humidity without reducing any of the actual moisture content. That’s why the air that comes out of a dehumidifier is warm.

Cold-coil dehumidifiers are designed to address the latent heat load. They do NOT move sensible BTUs out of a space and will actually increase the sensible heat load.

Solid Desiccant Dehumidification

Even though cold-coil dehumidifiers manage to run coil temperatures lower than most HVAC systems, those coil temperatures can’t go too low. Water freezes at 32°F, so the coil can ice up if it gets too cold and has all that moisture on it.

In cases where we need to maintain really low dew points, like 40°F or lower, we need to rely on a technology that doesn’t have a freezing risk. That’s where solid desiccant dehumidification comes in. This technology uses a desiccant medium, usually silica gel, to adsorb moisture from the air. That’s not a typo; adsorption happens when a material holds a liquid or vapor molecule on a surface.

Adsorption and Desorption

In desiccant dehumidification, water molecules attach to the desiccant media and remain on it as a thin film. Desiccant materials, like the silica gel you often see in deliveries or newly purchased backpacks, seek moisture and can have their vapor pressure manipulated. At room temperature or cooler, this vapor pressure is very low, and the vapor pressure of the surrounding area is usually much higher. Following the rules of energy, the water vapor in the air will move from an area of high pressure to one of low pressure (the desiccant) and cling to the surface.

The desiccant medium is porous, and these pores will hold that moisture, which doesn’t condense and drain out. You can heat the desiccant medium to raise the vapor pressure and cause the moisture to be desorbed or pulled away from the desiccant. Once the moisture has been removed, we can cool the desiccant medium again, and it will be able to resume its job.

This adsorption-desorption cycle happens via a wheel that rotates between two airstreams. One of those airstreams has contact with the cold, dry desiccant that can adsorb moisture. As the desiccant adsorbs more and more moisture, the wheel rotates to another airstream that’s warmer and can desorb that moisture, drying the desiccant. Then, the wheel rotates again, the temperature drops, and the desiccant can adsorb moisture again.

The benefit of this adsorption-desorption cycle is that there is no freezing risk from moisture because there is no liquid water on the surface. Because there is no cold, dripping surface with a risk of freezing, solid desiccant dehumidification strategies have potentially greater moisture removal capacities than cold-coil dehumidification.

How Heat Works in Both

Both forms of dehumidification rely on heat. In a cold-coil system, that heat comes from the refrigeration cycle; we have a cold coil filled with refrigerant, a compressor that rapidly heats and pressurizes the refrigerant, and a warm coil past the compressor. As the cooled and dried air passes over that warm coil, it heats up again. That air could be 10–15°F warmer than when it first came into the dehumidifier!

In an ideal world, that reheat doesn’t negatively affect the occupants’ comfort. The dehumidifier supply should tie into the central HVAC supply and have adequate time to mix before it reaches the register. However, the dehumidifier adds sensible BTUs regardless, and that can actually be a slight positive if it contributes to longer runtimes in well-built, tight structures (which gives the main air conditioning system more time to dehumidify as well; after all, the main HVAC is the king, and the dehumidifier is the queen).

In desiccant dehumidification, we use heat to raise the vapor pressure of the desiccant and desorb the moisture. That doesn’t happen within the airstream that will condition the space, so there is no “reheat” to account for when it comes to comfort. However, there needs to be a heat source to create the differential needed to dry the desiccant. Despite not having a compressor like a cold-coil dehumidifier, there still needs to be an energy input. This input is often electric heat, but it could also come from natural gas, steam, or even waste heat from other equipment.

Waste heat, such as from a chiller or water heater, would be the most efficient energy input. That way, power is only consumed to operate the fans and wheel, not to add electric heat.

Applications & Emerging Technologies

Both forms of dehumidification are used in a range of applications, but it’s more common to see cold-coil dehumidification in residential and light commercial applications (think strip malls and small retail and service buildings). Desiccant dehumidification is more common in larger commercial and specialized buildings. For example, hospitals and electronics factories have very specific humidity limits, and desiccant dehumidification is really the most practical way to maintain those.

Current Cold-Coil Dehumidifier Capabilities and Points to Consider

Again, residential applications are the most common for cold-coil dehumidification. There are dehumidifiers that can focus on individual spaces, especially moisture-prone basements and crawl spaces, and there are also whole-home dehumidifiers. In-wall dehumidifiers can also be installed as individual units in multifamily applications.

The most common light commercial applications include self-storage units, gyms, military housing, and pet stores and grooming facilities. All of those facilities either have property or occupants to protect from harm or are high-moisture environments by nature (due to showering, fish tanks, etc.).

The largest cold-coil dehumidifier that Santa Fe produces can remove 205 pints per day, which usually works best for 5000 square feet. That’s a relatively new offering with greater capacity than the ones before it.

Santa Fe’s ventilating dehumidifiers are going to support larger 8” ducts to meet ASHRAE 62.2 building requirements and work with the dehumidifier capacity. Smaller ducts led to dehumidifier oversizing, which caused shorter runtimes and more cycling on and off.

When selecting a dehumidifier, just like a central HVAC system, we want the capacity to match and not exceed the load as much as possible. That’s where the larger ventilation air ducts will come in handy. The same can be said for the development of a microchannel heat exchanger to pre-cool the air to help it reach the dew point faster without upsizing.

Current Desiccant Dehumidification Capabilities and Points to Consider

Desiccant dehumidification is used in most applications beyond what the cold-coil dehumidifiers can handle. It can dehumidify in far lower temperatures and on a larger scale, especially when we’re trying to maintain dew points below 50°F (and especially below freezing, at which the dew point would become the frost point).

Again, in a traditional dehumidifier, the coil needs to be below the dew point to work. We clearly can’t get below freezing with a traditional dehumidifier because water will just freeze on the coil, rendering it ineffective. Desiccant dehumidification can and does work with dew points below freezing, making it quite possibly the only viable choice for some industries that require those heavily controlled humidity conditions.

You will see desiccant dehumidification in heavy commercial and industrial applications. Here are some common mission-critical applications that use desiccant dehumidification:

- Food packing plants

- Lithium-ion battery manufacturing plants

- Hospitals

- Aerospace defense contracting facilities

- Pharmaceutical packaging facilities

On top of that, desiccant dehumidification can enhance older or inadequate commercial HVAC equipment (including DOAS systems). These cases are common when grocery spaces are repurposed; while the equipment might’ve been good enough to maintain about 50–60% RH in the original application, it’s not able to get much lower. Desiccant dehumidification systems can decouple the latent load from the sensible load, allowing the HVAC systems to focus solely on the sensible load.

What About Hybrid Systems?

As you can see, the applications of each dehumidification strategy don’t have a lot of overlap. While refrigerant-based cold-coil dehumidifiers are usually used for comfort in residential and light commercial applications, desiccant dehumidification is mostly used in heavy commercial and industrial applications.

That doesn’t mean they can’t work together. The strongest cases to be made for hybrid designs are in applications that require a massive range of operation, whether due to the facility’s nature or the climate.

Many facilities are multipurpose; there are comfort and industrial elements. In hospitals and medical facilities, there are patient waiting areas and mission-critical operating rooms. Traditional cold-coil dehumidifiers might work well for comfort, especially if added sensible heat isn’t a huge problem for the HVAC system design and equipment selection. However, desiccant dehumidification might offer greater moisture removal in areas that have a tight range of acceptable sensible and humidity conditions, like in labs or operating rooms.

Similarly, athletic clubs, gyms, and some hotels that have indoor pools have massive latent heat loads. Desiccant dehumidification could give traditional dehumidification systems a boost to handle those high latent loads, while other indoor spaces that don’t need the same degree of drying could work with a traditional dehumidifier.

The other case that would require a dehumidification system to handle a massive range of operation is one where we have wide variations in temperature and consistently high humidity. When dew points are high, a cold-coil dehumidifier is the most sensible decision (at the expense of sensible heat gains). When dew points and temperatures are low with a high relative humidity, desiccant dehumidification can step in and handle what the traditional dehumidifier cannot.

Once again, it’s helpful to think of desiccant dehumidification as the technology that can step up where traditional dehumidification’s capabilities end. With a greater emphasis on machine learning and the use of sensors and controls to adjust system operation, it isn’t beyond the realm of possibility to imagine a system that runs a traditional dehumidifier until a dew point sensor shuts it off and opts to run a desiccant dehumidification system instead.

Comments

To leave a comment, you need to log in.

Log In