Get Tech Tips

Subscribe to free tech tips.

What is RS-485 Communication?

This tech tip about RS-485 communication is the third installment in a four-part series about oscilloscopes. It's a primer for the final installment about using an oscilloscope for diagnosis. I owe a special thanks to Jeremy Smith for sharing the information on Danfoss and for sparking my curiosity surrounding this type of communication.

Let's talk about the unsung hero behind many of our refrigeration network communications: RS-485. You may have heard it mentioned with MOD-bus and LON-bus systems, but what exactly is it, and why is it so good at what it does?

Noise Cancellation

Imagine you're trying to send an important message across a busy factory floor. If you just shout, all the machinery noise will drown out your words, and your message gets lost in the “noise.”

Electrical signals face the same challenge; they can pick up interference. But RS-485 has a brilliant solution. It's like a special, noise-canceling conversation. Instead of sending one signal, it sends two, always opposite each other. Think of it like this: one wire sends a “positive” signal, and the other sends an identical “negative” signal. This is what we call a balanced system. The receiving device doesn't look at each signal individually; it only looks at the difference between the two.

Why is this so smart? Because if a burst of electrical noise hits the wires, it usually affects both of them equally. Since the receiver is only interested in the difference, that common noise gets canceled out! It's as if the entire factory floor suddenly got louder, but you and a friend are communicating by focusing on reading each other’s lips; the background noise doesn't interfere as much. This technique allows RS-485 to send signals clearly and reliably, even over long distances and through very noisy industrial environments.

How the Wiring Looks

There are two wires, besides the ground, dedicated to carrying the signal. The magic happens because the signal on one wire is designed to be the exact opposite of the signal on the second wire. So, if one wire is transmitting a ‘high' signal, the other is transmitting a ‘low' signal, and vice versa. We don’t just run the wires side by side. We use something called ‘twisted pair' wiring. As the name suggests, it's literally a pair of wires of equal length twisted together.

Source: PicoScope 2204A 10 MHz Oscilloscope User Guide, pg. 11, Figure 1

Source: PicoScope 2204A 10 MHz Oscilloscope User Guide, pg. 11, Figure 2

When you're sending high-speed data, especially over long distances, those fast signal changes create high-frequency components. These high frequencies, combined with long, straight wires, can act like little antennas and radiate EMI – essentially, they broadcast unwanted electromagnetic noise. But with a twisted pair, since the signals on each wire are equal but opposite, the radiated signals from each wire also tend to be equal and opposite. They essentially cancel each other out, making the system a very inefficient radiator of EMI. It's like two waves hitting each other and flattening out.

Source: PicoScope 2204A 10 MHz Oscilloscope User Guide, pg. 12, Figure 3

The twisting also helps immensely with received EMI. Your network wiring can pick up unwanted signals, just like an antenna. This external noise can distort our precious data signals. But because the two wires in a twisted pair are so close together and twisted, any noise they pick up tends to be the same on both wires; this is what we call common-mode noise. And here's the clever part: RS-485 receivers are designed to look for signals that are opposite to each other. So, if the noise is the same on both wires, the receiver simply ignores it, effectively rejecting that common-mode noise. It's incredibly effective at maintaining signal integrity.

Another powerful feature of RS-485 is its “multi-drop” capability, which means you can connect many different devices to the same two wires. Imagine a single main highway, and all your sensors and controllers have their own off-ramps onto it. That significantly reduces the amount of wiring needed, saving time and resources during installation.

Limitations of RS-485 Communication

While RS-485 is robust, it does have a few fundamental rules and limitations to keep in mind.

First, RS-485 only carries the message itself. It does not carry power. Therefore, every sensor, valve, or controller connected to an RS-485 bus will still require its own separate power supply wire.

Second, there's a tradeoff between speed and distance. If you need to send messages very quickly, you can't send them over very long distances. Conversely, if you need to send messages over a long distance, you'll need to slow down the communication speed. Also, on this shared highway, only one device can “talk” at a time; this is called half-duplex communication. The system has built-in traffic management to ensure messages don't collide.

Finally, we need some guardrails in place: termination resistors.

Characteristic Impedance and Termination Resistors

Every cable has something called a characteristic impedance. For RS-485, the recommendation is typically 120 ohms. This impedance is crucial for predictable signal behavior, which brings us to termination resistors. These are simply resistors placed at the very ends of the cable. Their value should ideally match the characteristic impedance of the cable.

Source: PicoScope 2204A 10 MHz Oscilloscope User Guide, pg. 13, Figure 4

On a long stretch of communication wire, electrical signals can “bounce back” like echoes. Termination resistors are small resistors, placed at each end of the RS-485 wire, that absorb these reflections, keeping the messages clean and preventing data corruption. Forgetting these or placing them incorrectly can lead to frustrating, intermittent communication problems. The oscilloscope will show this clearly as a messy, distorted waveform.

By matching the termination resistor to the cable's characteristic impedance, we absorb the signal at the end, preventing reflections and ensuring a clean, square waveform.

Source: PicoScope 2204A 10 MHz Oscilloscope User Guide, pg. 13, Figure 5

RS-485 in Refrigeration

In a large cold storage facility, you'll find countless sensors measuring temperature, pressure, and humidity, along with motors, valves, and defrost heaters that need precise instructions. RS-485 connects all these distributed components to the central control unit. It allows for remote control and monitoring without the need for a massive, tangled web of individual wires. The system is also scalable: if you need to add another freezer room or more sensors, you can usually tap into the existing RS485 highway, easily integrating new devices.

For facility managers, RS-485 is invaluable for centralized monitoring. Instead of physically checking every gauge, they can view all critical data—temperatures, pressures, alarm statuses—in real-time from a single screen. RS-485 brings all this data back to one central location, enabling quick identification and resolution of issues, preventing costly product spoilage.

The noise-canceling ability of RS-485 is also a huge advantage in refrigeration plants, which are often filled with electrical interference from large motors and power lines. RS-485's reliability in noisy environments ensures that critical data is always transmitted accurately.

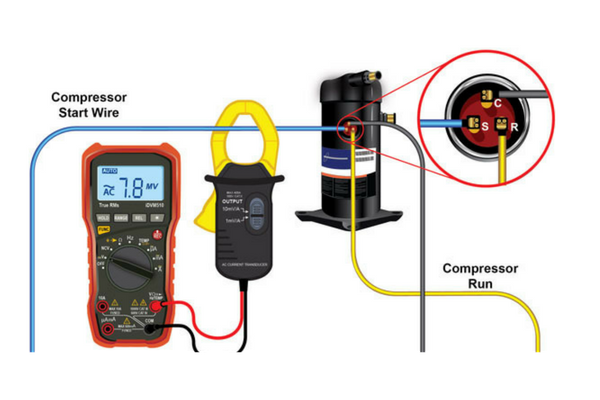

You'll find RS-485 wires connected to:

- Temperature and humidity sensors (providing precise environmental data)

- Compressor controllers (receiving commands to adjust their operation)

- Electronic expansion valves (EEVs) (precisely regulating refrigerant flow)

- Fan speed controllers (optimizing airflow based on cooling needs)

- Local display panels on refrigeration units

RS-485 also serves as the link between refrigeration systems and larger Building Management Systems (BMS), allowing for integrated facility control.

Protocols on RS-485

RS-485 provides the physical “highway” for communication, but devices still need a common language or set of “traffic rules” to understand each other. These are known as communication protocols.

The most common language you'll encounter in industrial and refrigeration settings is Modbus. It's a simple, widely understood language, like basic English. One device (the “master”) asks questions or sends commands, and the other devices (the “slaves”) respond. Modbus is excellent for basic data exchange, like getting a temperature reading from a sensor or telling a compressor to start. Its simplicity makes it a very common “universal translator” between equipment from different manufacturers.

Then there's BACnet. This is a more advanced and comprehensive language, specifically designed for building automation systems (BAS). If a refrigeration system needs to share detailed information with other building systems like lighting, security, or HVAC, BACnet is often the preferred choice. It allows for a much smarter, more integrated building environment.

Finally, you might encounter “secret languages” or proprietary protocols. Some manufacturers develop their own specific communication protocols that run over RS-485, tailored to their unique equipment features. It's like they have their own private code. If you need their equipment to communicate with devices from other manufacturers, you often require a special “translator box” (a gateway) to convert their secret language into a more universally understood protocol like Modbus or BACnet.

So, in a nutshell, we use RS-485 because its balanced, twisted-pair design, combined with proper termination, makes it incredibly resilient to noise and signal degradation. This combination allows for reliable data communication over significant distances in our refrigeration control systems. It's all about ensuring that the message gets from point A to point B, clear as a bell, every single time.

—Roman Baugh

Comments

To leave a comment, you need to log in.

Log In