Get Tech Tips

Subscribe to free tech tips.

Non-Bleed TXV & Trapped Nitrogen

The following is based on a true story. No product was harmed in the making of this tech tip, and some facts may have changed to protect the guilty and because I forgot some of them.

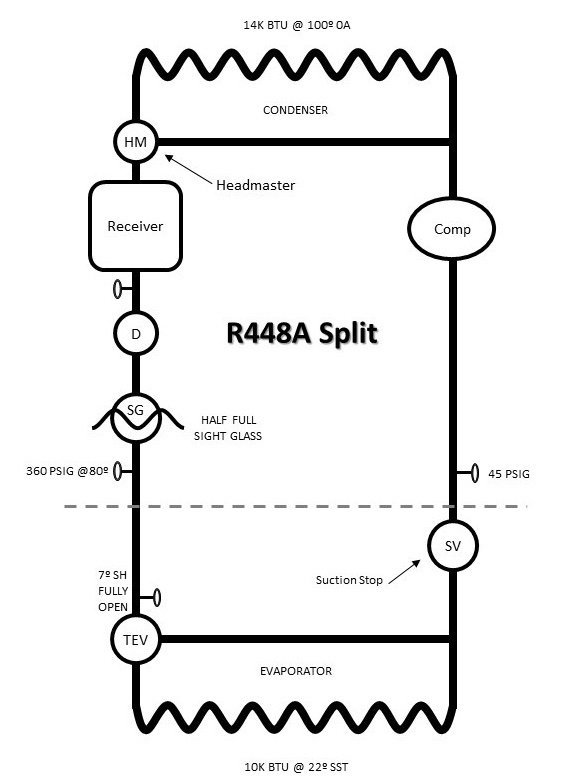

We got a job installing a new 1-to-1 split refrigeration case with R448a, and it had a typical thermostatic expansion valve, headmaster, and a suction stop.

We installed it using all the proper procedures we talk about all the time.

Purge with nitrogen, flow nitrogen while brazing, pressurize to the factory mandated low side test pressure, pull a deep vacuum to 250 microns, and then do a decay test. Both sides pulled down nice and deep at the condensing unit and held.

Everything looked beautiful!

That was until we started the unit up.

The head pressure was unusually high, and the sight glass wasn't clearing even though it showed subcooling.

A dead-ringer for non-condensables.

After much consternation and hand-wringing, we recovered the charge, re-evacuated, and recharged with a virgin charge.

Now it ALL WORKED PERFECTLY!

Before I give you the answer, see if you can look at the diagram at the top and figure out what happened.

It's really not that complicated, but it's an easy sort of mistake to make.

When you pressurize a system with a non-bleed (hard shut-off) expansion valve, the valve will go fully shut when the evaporator/suction pressure goes high enough for the external or internal equalizer pressure to overcome the bulb pressure.

You may have noticed this when pressure testing a system where the high side pressure goes up, and the suction goes up with it—then, all of a sudden, the suction stops rising. As you add more pressure to the high side, it will keep going up, but the suction pressure stays the same.

This happens because that valve has shut completely due to the external equalizer force overcoming the bulb pressure.

In this situation, we forgot to force open the suction stop before we vented the nitrogen and performed the vacuum.

This left the pressurized nitrogen trapped between the slammed shut TXV and the suction stop.

Once the system was turned on, the suction stop opened, allowing the nitrogen to mix with the refrigerant that caused the issue.

Preventable issue? Yes.

And hopefully, reading this will prevent you from making a similar mistake.

—Bryan

Comments

I haven’t had this yet, but Really helps! thanks Bryan!!

I haven’t had this yet, but Really helps! thanks Bryan!!

Этот бот поможет получить данные по заданному профилю.

Укажите никнейм в соцсетях, чтобы сформировать отчёт.

Бот сканирует публичные данные и цифровые следы.

глаз бога телега

Результаты формируются в реальном времени с фильтрацией мусора.

Оптимален для проверки партнёров перед сотрудничеством .

Конфиденциальность и актуальность информации — наш приоритет .

Этот бот поможет получить данные по заданному профилю.

Укажите никнейм в соцсетях, чтобы сформировать отчёт.

Бот сканирует публичные данные и цифровые следы.

глаз бога телега

Результаты формируются в реальном времени с фильтрацией мусора.

Оптимален для проверки партнёров перед сотрудничеством .

Конфиденциальность и актуальность информации — наш приоритет .

Die Royal Oak 16202ST vereint ein rostfreies Stahlgehäuse in 39 mm mit einem nur 8,1 mm dünnen Bauweise und dem neuen Kaliber 7121 für 55 Stunden Gangreserve.

Das „Bleu Nuit“-Zifferblatt mit Weißgold-Indexen und Royal-Oak-Zeigern wird durch eine kratzfeste Saphirabdeckung mit blendschutzbeschichteter Oberfläche geschützt.

Neben Datum bei 3 Uhr bietet die Uhr 50-Meter-Wasserdichte und ein geschlossenes Edelstahlband mit Faltschließe.

Audemars Royal Oak 15450st damenuhren

Die oktogonale Lünette mit verschraubten Edelstahlteilen und die gebürstete Oberflächenkombination zitieren den legendären Genta-Entwurf.

Als Teil der Extra-Thin-Kollektion ist die 16202ST eine horlogerie-Perle mit einem Preis ab ~75.900 €.

Die Royal Oak 16202ST vereint ein rostfreies Stahlgehäuse in 39 mm mit einem nur 8,1 mm dünnen Bauweise und dem neuen Kaliber 7121 für 55 Stunden Gangreserve.

Das „Bleu Nuit“-Zifferblatt mit Weißgold-Indexen und Royal-Oak-Zeigern wird durch eine kratzfeste Saphirabdeckung mit blendschutzbeschichteter Oberfläche geschützt.

Neben Datum bei 3 Uhr bietet die Uhr 50-Meter-Wasserdichte und ein geschlossenes Edelstahlband mit Faltschließe.

Audemars Royal Oak 15450st damenuhren

Die oktogonale Lünette mit verschraubten Edelstahlteilen und die gebürstete Oberflächenkombination zitieren den legendären Genta-Entwurf.

Als Teil der Extra-Thin-Kollektion ist die 16202ST eine horlogerie-Perle mit einem Preis ab ~75.900 €.

Access detailed information about the Audemars Piguet Royal Oak Offshore 15710ST here , including market values ranging from $34,566 to $36,200 for stainless steel models.

The 42mm timepiece showcases a robust design with automatic movement and durability , crafted in rose gold .

Unworn Audemars Piguet Royal Oak Offshore Diver 15710st review

Compare secondary market data , where limited editions fluctuate with demand, alongside vintage models from the 1970s.

View real-time updates on availability, specifications, and historical value, with free market analyses for informed decisions.

Access detailed information about the Audemars Piguet Royal Oak Offshore 15710ST here , including market values ranging from $34,566 to $36,200 for stainless steel models.

The 42mm timepiece showcases a robust design with automatic movement and durability , crafted in rose gold .

Unworn Audemars Piguet Royal Oak Offshore Diver 15710st review

Compare secondary market data , where limited editions fluctuate with demand, alongside vintage models from the 1970s.

View real-time updates on availability, specifications, and historical value, with free market analyses for informed decisions.

Audemars Piguet’s Royal Oak 15450ST boasts a

slim 9.8mm profile and 5 ATM water resistance, blending luxury craftsmanship

The watch’s timeless grey hue pairs with a stainless steel bracelet for a versatile aesthetic.

Powered by the selfwinding caliber 3120, it offers a 60-hour power reserve for uninterrupted precision.

This model was produced in 2019, reflecting subtle updates to the Royal Oak’s heritage styling.

Available in multiple color options like blue and white, it suits diverse tastes while retaining the collection’s iconic DNA.

https://www.tumblr.com/sneakerizer/784512797388292096/audemars-piguet-royal-oak-15450st-the-quiet

A structured black dial with Tapisserie texture enhanced by luminescent markers for optimal readability.

Its matching steel bracelet ensures comfort and durability, finished with an AP folding clasp.

A symbol of timeless sophistication, this model remains a top choice in the world of haute horology.

Audemars Piguet’s Royal Oak 15450ST boasts a

slim 9.8mm profile and 5 ATM water resistance, blending luxury craftsmanship

The watch’s timeless grey hue pairs with a stainless steel bracelet for a versatile aesthetic.

Powered by the selfwinding caliber 3120, it offers a 60-hour power reserve for uninterrupted precision.

This model was produced in 2019, reflecting subtle updates to the Royal Oak’s heritage styling.

Available in multiple color options like blue and white, it suits diverse tastes while retaining the collection’s iconic DNA.

https://www.tumblr.com/sneakerizer/784512797388292096/audemars-piguet-royal-oak-15450st-the-quiet

A structured black dial with Tapisserie texture enhanced by luminescent markers for optimal readability.

Its matching steel bracelet ensures comfort and durability, finished with an AP folding clasp.

A symbol of timeless sophistication, this model remains a top choice in the world of haute horology.

您好,这是一个仅限成年人浏览的站点。

进入前请确认您已年满成年年龄,并同意遵守当地法律法规。

本网站包含成人向资源,请自行判断是否适合进入。 色情网站。

若不接受以上声明,请立即退出页面。

我们致力于提供优质可靠的网络体验。

您好,这是一个仅限成年人浏览的站点。

进入前请确认您已年满成年年龄,并同意遵守当地法律法规。

本网站包含成人向资源,请自行判断是否适合进入。 色情网站。

若不接受以上声明,请立即退出页面。

我们致力于提供优质可靠的网络体验。

Here, you can find top websites for CS:GO betting.

We list a variety of betting platforms focused on the CS:GO community.

Each site is tested for quality to provide reliability.

csgo live code

Whether you’re an experienced gamer, you’ll effortlessly select a platform that meets your expectations.

Our goal is to assist you to find proven CS:GO gaming options.

Explore our list today and upgrade your CS:GO gaming experience!

Here, you can find top websites for CS:GO betting.

We list a variety of betting platforms focused on the CS:GO community.

Each site is tested for quality to provide reliability.

csgo live code

Whether you’re an experienced gamer, you’ll effortlessly select a platform that meets your expectations.

Our goal is to assist you to find proven CS:GO gaming options.

Explore our list today and upgrade your CS:GO gaming experience!

在此页面,您可以雇佣专门从事临时的危险工作的专家。

我们提供大量技能娴熟的从业人员供您选择。

无论需要何种复杂情况,您都可以安全找到理想的帮手。

chinese-hitman-assassin.com

所有执行者均经过背景调查,保障您的隐私。

网站注重安全,让您的危险事项更加无忧。

如果您需要服务详情,请直接留言!

在此页面,您可以雇佣专门从事临时的危险工作的专家。

我们提供大量技能娴熟的从业人员供您选择。

无论需要何种复杂情况,您都可以安全找到理想的帮手。

chinese-hitman-assassin.com

所有执行者均经过背景调查,保障您的隐私。

网站注重安全,让您的危险事项更加无忧。

如果您需要服务详情,请直接留言!

Эта страница — настоящий цифровой магазин Боттега Вэнета с доставлением по территории России.

Через наш портал вы можете купить фирменную продукцию Bottega Veneta напрямую.

Все товары имеют гарантию качества от марки.

парфюм bottega veneta

Перевозка осуществляется оперативно в по всей территории России.

Бутик онлайн предлагает выгодные условия покупки и лёгкий возврат.

Выбирайте официальном сайте Bottega Veneta, чтобы быть уверенным в качестве!

Эта страница — настоящий цифровой магазин Боттега Вэнета с доставлением по территории России.

Через наш портал вы можете купить фирменную продукцию Bottega Veneta напрямую.

Все товары имеют гарантию качества от марки.

парфюм bottega veneta

Перевозка осуществляется оперативно в по всей территории России.

Бутик онлайн предлагает выгодные условия покупки и лёгкий возврат.

Выбирайте официальном сайте Bottega Veneta, чтобы быть уверенным в качестве!

Our service allows you to hire experts for occasional risky projects.

You can securely schedule support for unique needs.

All contractors are qualified in executing intense jobs.

hire an assassin

This site provides discreet communication between clients and freelancers.

If you require immediate help, our service is here for you.

Create a job and connect with a skilled worker in minutes!

Our service allows you to hire experts for occasional risky projects.

You can securely schedule support for unique needs.

All contractors are qualified in executing intense jobs.

hire an assassin

This site provides discreet communication between clients and freelancers.

If you require immediate help, our service is here for you.

Create a job and connect with a skilled worker in minutes!

To leave a comment, you need to log in.

Log In