BACK

Condenser Fan Blade Placement

Condenser Fan Blade Placement

Motor Overheating

Motor Overheating

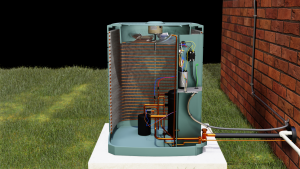

How to Replace a Condensing Fan Motor

How to Replace a Condensing Fan Motor

Aftermarket Motor Selection & Considerations

Aftermarket Motor Selection & Considerations

Motor Ambient Rating – Short #241

Motor Ambient Rating – Short #241

#condensing fan motor

Tech Tips:

In a previous article, I talked about wiring permanent split capacitor (PSC) condenser fan motors. While researching the topic, I realized that there isn’t as much information available on condenser motors as there is on their counterpart—the indoor blower motor. I had never really given it much thought, as I assumed that the condenser motor […]

Read more

An important rating on motors is the AMBIENT temperature rating that the motor can operate at. This rating refers to the temperature of the air around the motor, not the temperature of the motor itself or even the temperature of the outdoor air—since the motor is often in a condenser air stream that is higher […]

Read more

Service calls about condensing fan motor failure are quite common. Even though fan motor replacement is a standard procedure for residential split systems, it requires careful attention to safety and detail. This article will give you a step-by-step guide to replacing condensing fan motors. Along the way, we will also explain a few best practices […]

Read more

This article was written by technician and HVAC School community star Kenneth Casebier. Thanks, Kenneth! When looking at replacing a single-phase A/C motor with an aftermarket motor from your van, there are a few things you should know and pay attention to. First, the factory OEM motor will always be the best option, especially when […]

Read morePodcasts:

In this short podcast episode, Bryan talks about what the ambient rating means on a motor. These ratings can be found on both condensing fan motors and blower motors. They have Cs in their rating, which represents the maximum ambient temperature the motor can handle in degrees Celsius (like 40C or 60C). Heat and […]

Read more