BACK

Crankcase Heaters

Crankcase Heaters

Crankcase Heaters and Single-Pole Contactors

Crankcase Heaters and Single-Pole Contactors

Locked Compressor Mistakes w/ Bert

Locked Compressor Mistakes w/ Bert

#crankcase heater

Tech Tips:

Belly band crankcase heater When I first started in the trade as an apprentice, we worked on many Trane heat pumps that used crankcase heaters. These crankcase heaters slid into the compressor sump on the big orange Tyler reciprocating compressors. They looked like the one in the picture below. It was very common for these […]

Read more

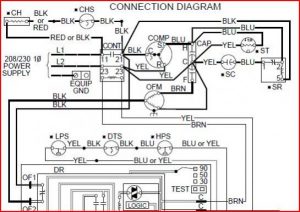

We keep two-pole, 40-amp 24v coil contactors on all of our vans. They are versatile and reliable, and you can replace most residential A/C contactors with them. There are a few things to watch for, though, especially when you have a crankcase heater. Many brands power the crankcase heater constantly and shut it on and […]

Read morePodcasts:

In this informative HVAC podcast episode, Bryan and Bert dive deep into the complex world of locked and internal overload compressors, focusing specifically on single-phase residential units. The discussion begins with Bert explaining one of the most common challenges technicians face: diagnosing a locked compressor. He describes how compressors that are locked will typically […]

Read more