BACK

Defrost Termination & Fail-Safe

Defrost Termination & Fail-Safe

Defrost Time & Temperature

Defrost Time & Temperature

#defrost termination

Tech Tips:

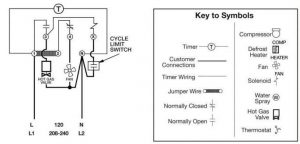

As an A/C tech, I can sometimes get the terms “defrost termination” and “defrost fail-safe” mixed up because they sound pretty similar. Before we cover these terms, let's set the basic defrost groundwork for refrigeration (coolers and freezers). Defrost is accomplished in one of a few ways; these first two only apply to “coolers” where […]

Read more

The most common method to defrost appropriately in refrigeration involves both time for initiation and a combination of time and temperature for defrost termination (ending defrost). But why can't we just use temperature or time alone? (You may wonder.) Imagine a common freezer with a designed box temperature of -10°F and a coil temperature of […]

Read more