BACK

Dielectric Grease: What It Is and How To Use It

Dielectric Grease: What It Is and How To Use It

Sensors, Measurements, and Physics

Sensors, Measurements, and Physics

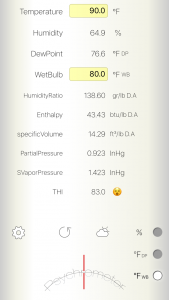

Coil SHR, Ventilation, and Bypass Factor – Advanced Psychrometrics Part 2

Coil SHR, Ventilation, and Bypass Factor – Advanced Psychrometrics Part 2

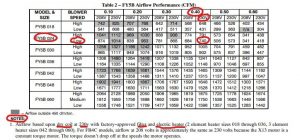

How to Use a Manufacturer Fan Table and Why They are Important

How to Use a Manufacturer Fan Table and Why They are Important

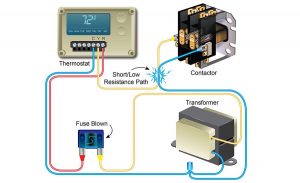

Locating a Low Voltage Short in Residential A/C Systems

Locating a Low Voltage Short in Residential A/C Systems

Ventilation, Filtration, and Humidity Control: The Holy Trinity of IAQ

Ventilation, Filtration, and Humidity Control: The Holy Trinity of IAQ

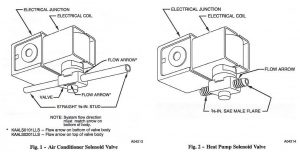

Liquid Line Solenoid Valves: Long Line Applications

Liquid Line Solenoid Valves: Long Line Applications

Using Power Factor to Check Capacitors Under Load

Using Power Factor to Check Capacitors Under Load

Improving Changeout Outcomes

Improving Changeout Outcomes

Spidey Sense – Airflow – Short #205

Spidey Sense – Airflow – Short #205

Preventing Low Voltage Issues

Preventing Low Voltage Issues

STOP Overthinking! – QA Short #204

STOP Overthinking! – QA Short #204

Duct Smoke Detector Facts and Wiring – Short #203

Duct Smoke Detector Facts and Wiring – Short #203

Trust the NEW Process: Embracing Evolution in HVAC Technology

Trust the NEW Process: Embracing Evolution in HVAC Technology

Soft Start & Solar – Short #202

Soft Start & Solar – Short #202

How Do Inverter Air Conditioners Work? – Short #201

How Do Inverter Air Conditioners Work? – Short #201

How to Size Dehums w/ Tim De Stasio

How to Size Dehums w/ Tim De Stasio

##hvacschool

Tech Tips:

Dielectric grease is an often misused and misunderstood product that could easily benefit HVAC/R technicians in various ways. From food service to electrical connections, dielectric grease can help lubricate mechanical components and prevent corrosion on electrical connections. But we need to understand what it is in the first place before we can properly apply it […]

Read more

As HVAC/R Technicians, we use tools and instruments to take measurements every day. In fact, 90% of our job could not be done efficiently without some kind of measurement. “How do we measure?” “With what instruments?” “How accurate are these measurements?” These are all questions a thoughtful technician should ask before spending money on a […]

Read more

This is the second article in a three-part series where we explore advanced psychrometrics. The source material for each of the articles in this series is ACCA Manual P Sections 3, 4, and 5. This article is based on information found in Section 4. If you followed the previous advanced psychrometrics article, you now know […]

Read more

Many installers and service technicians know how to read and use a manufacturer fan table, but this is a quick review with a few extra tips for newer techs. It’s also a good reminder to senior technicians about how this easy-to-use practice can also be easily abused. At installation, properly setting up airflow is imperative to the […]

Read more

Newer technicians often get hung up and frustrated when searching for low voltage shorts. This is understandable due to the broad spectrum of possibilities for the location of the short. However, this doesn’t mean that the process needs to be complex. The time it takes to find a low voltage short may vary greatly depending […]

Read more

At the time of the publication of this article, COVID-19 (coronavirus) is spreading across the world at an alarming rate, and many people have self-quarantined to help slow or stop the spread of the virus. These precautionary measures are prudent and responsible. However, with the increased amount of time people spend inside their homes, there […]

Read more

Pump down solenoid valves are commonplace for any refrigeration technician. They are energized with the compressor still running, shutting off flow in the liquid line so that the refrigerant is pumped into the condenser and receiver. The compressor will then shut off once a low-pressure switch opens the circuit when the pressure falls below a […]

Read more

Capacitors are traditionally tested with a capacitance meter (commonly found as a function within a multimeter), with the component taken entirely out of the circuit. “Bench testing,” as this method is referred to, is hands-down the safest method of checking capacitance in microfarads. All other methods require the capacitor to be wired into the circuit […]

Read moreVideos:

Podcasts:

In this episode, we dive deep into the world of residential HVAC installations with Matt, a senior technician and residential install supervisor at Kalos Services. Matt brings a wealth of experience from both the service and installation sides of the business, offering valuable insights into improving installation processes and workmanship. The conversation highlights the importance […]

Read more

In this short podcast, Bryan talks about how to pay close attention to airflow issues and use your “spidey sense” when you're doing a visual inspection or commissioning a system. He also covers some causes of common airflow problems and some services and upgrades you can offer to your customers. The skill of being […]

Read more

In this episode, Bryan and Bert dive deep into the world of low voltage wiring in HVAC systems. They discuss common mistakes, best practices, and troubleshooting techniques that technicians and contractors should be aware of when dealing with control wiring. The conversation begins with a focus on mechanical issues, such as running wires in places […]

Read more

In this short podcast from our Q&A series, Bryan answers a viewer question and implores you to STOP overthinking in the trade! He also shares a parable and some tips to help stop overthinking, especially if you're just starting out in the trade. In many cases, the simplest assumption is the right one (this is […]

Read more

In this short podcast, Bryan answers a listener-submitted question about duct smoke detector facts and wiring. He focuses on Honeywell duct smoke detectors (namely the D4120W), but there are some general best practices that can be applied to most duct smoke detectors. The power supply may be 24v or 120v AC or DC and may […]

Read more

In this episode of the HVAC School podcast, host Bryan and guest Jesse Stewart from NAVAC discuss the generational divide in the HVAC industry and the importance of embracing new technologies and processes. They explore the challenges faced by both experienced technicians who may be set in their ways and newcomers to the trade who need […]

Read more

In this short podcast episode, Bryan dives into soft start & solar technology, which often work together. He also talks about how we can install ductless systems in homes that rely on solar power. Soft starts are NOT hard starts. Hard starts add more current to the start (auxiliary) winding, which creates a stronger […]

Read more

In this short podcast episode, Bryan answers a listener-submitted question: How do inverter air conditioners work? Inverter-driven systems have variable capacity to match loads. We can provide cooling or heating BTUs to match the needs of the space without overcompensating or undercompensating and causing temperature swings. Load matching also helps us get better efficiency […]

Read more

In this episode of the HVAC School podcast, host Bryan Orr interviews Tim De Stasio, an experienced HVAC practitioner and consultant. Tim shares his journey in the HVAC industry, from his early days in vocational school to running his own contracting business for 12 years. He now focuses on consulting, design, and contractor training, […]

Read more