Why Compressors Fail: Diagnosis, Replacement & Prevention

December 3, 2025

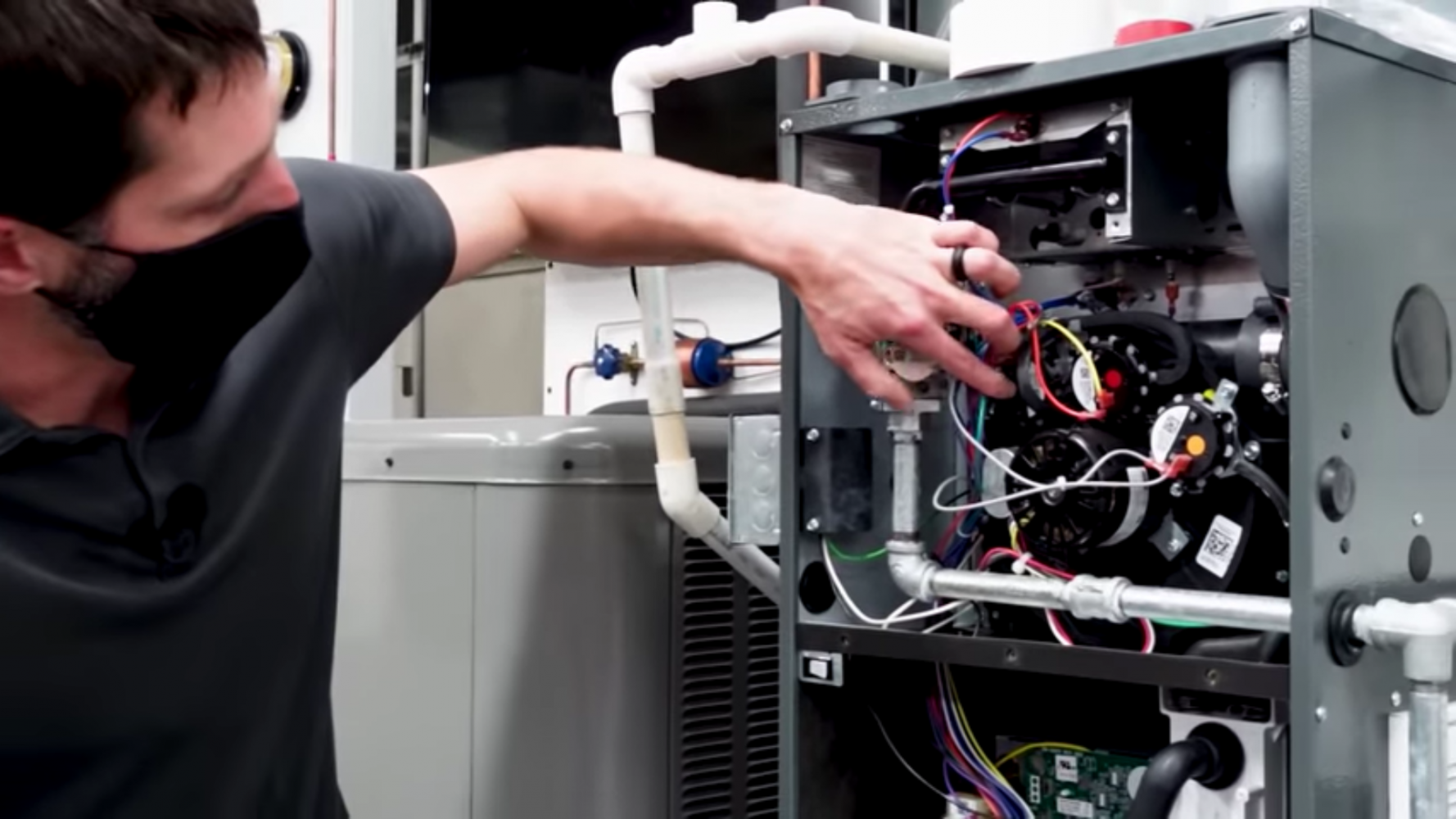

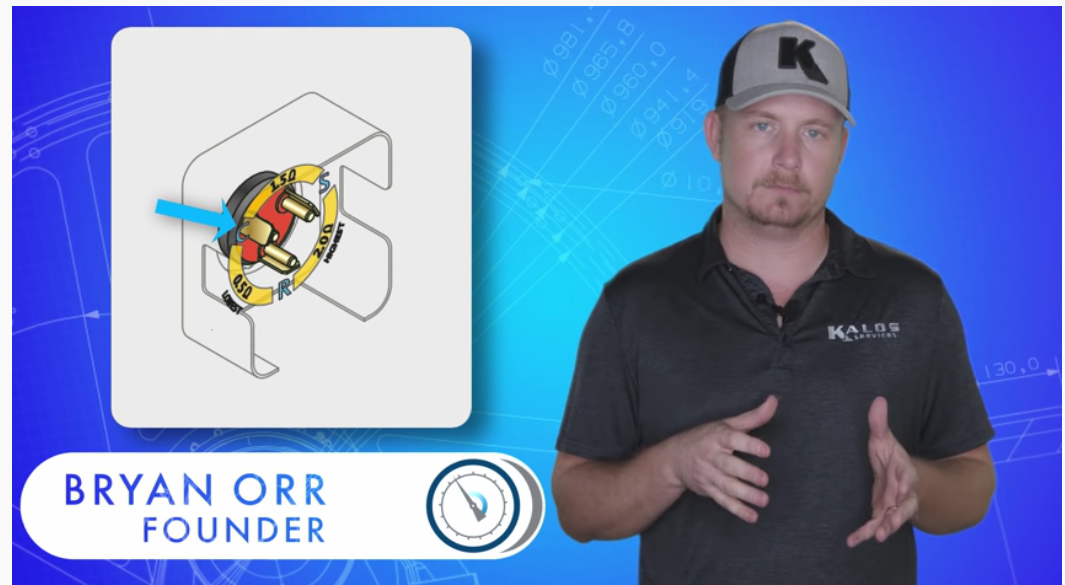

In this comprehensive HVAC training video, we explore why compressors fail and provide expert guidance on diagnosis techniques, replacement procedures, and prevention strategies to avoid costly callbacks.

Comments

To leave a comment, you need to log in.

Log In