Get Tech Tips

Subscribe to free tech tips.

Liquid Line Solenoid Valves: Long Line Applications

Pump down solenoid valves are commonplace for any refrigeration technician. They are energized with the compressor still running, shutting off flow in the liquid line so that the refrigerant is pumped into the condenser and receiver. The compressor will then shut off once a low-pressure switch opens the circuit when the pressure falls below a set pressure. However, there are other applications for which liquid line solenoid valves are useful. Long line applications in HVAC incur a wide range of challenges a technician must evaluate. Those challenges include oil return, refrigerant migration in off-cycle, compressor workload, efficiency or capacity losses, added refrigerant charge, and metering device selection.

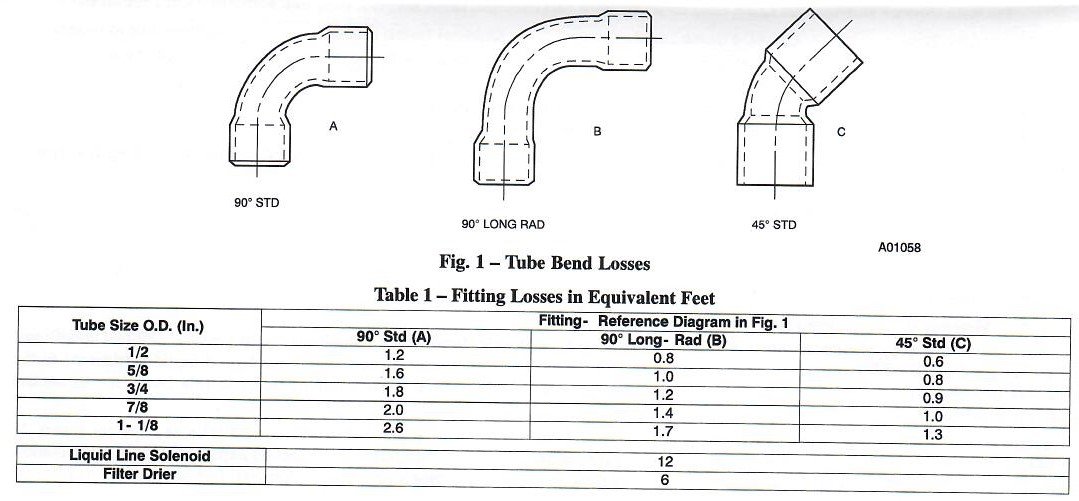

Long line applications (for R410a straight A/C and heat pumps with ⅜” liquid lines) are generally defined as any system with a line set longer than 80 ft in equivalent length. Equivalent length in this context means that all pressure drops (copper fittings, bends, diameter size changes) translate to a length equivalent to a run of straight copper. Manufacturer spec data for copper fittings will have printed the equivalent length of those fittings in its literature. The length to be exceeded before long line application procedures are used may vary depending on line set diameter size and on which plane the indoor and outdoor units are located, but 80 ft is the general rule for Residential AC and HPs. Any system with a 20 ft uninterrupted vertical rise in the line set should also be treated as a long line application, per Carrier’s Long Line Application Guideline. You can read that document HERE.

There are many ways manufacturers have sought to resolve the challenges with long line applications. Some of these solutions include crankcase heaters and TXV metering devices. Most manufacturers will specify an OEM hard-start kit to protect compressor effectiveness against the added refrigerant charge. Some commercial applications require oil traps to aid in oil return.

Liquid line solenoid valves are specifically utilized to prevent refrigerant migration in the off-cycle. The valve is positioned with the arrow printed on the valve body pointing toward the outdoor unit. For heat pumps, the valve must be biflow. It is important to note that the valve is normally closed in these long line applications. When energized with the contactor of the outdoor unit, the coil in the valve body will pull the valve open to allow flow. However, when closed, the valve only stops refrigerant from flowing in the direction of the arrow printed on the valve. With the system in the off-cycle, the solenoid valve will keep refrigerant liquid and vapor from migrating to the compressor down the liquid line. But don't let the refrigerant tubing size fool you! Just because the liquid line is 3/8″ doesn't mean any liquid line solenoid valve with 3/8″ sweat or flare connections will do. Care must be taken when selecting a solenoid valve. Choose valves to match the capacity of the system on which it will be installed (with a pressure drop of no more than 1 PSI), then pay attention to refrigerant rating, THEN select them by line set diameter size.

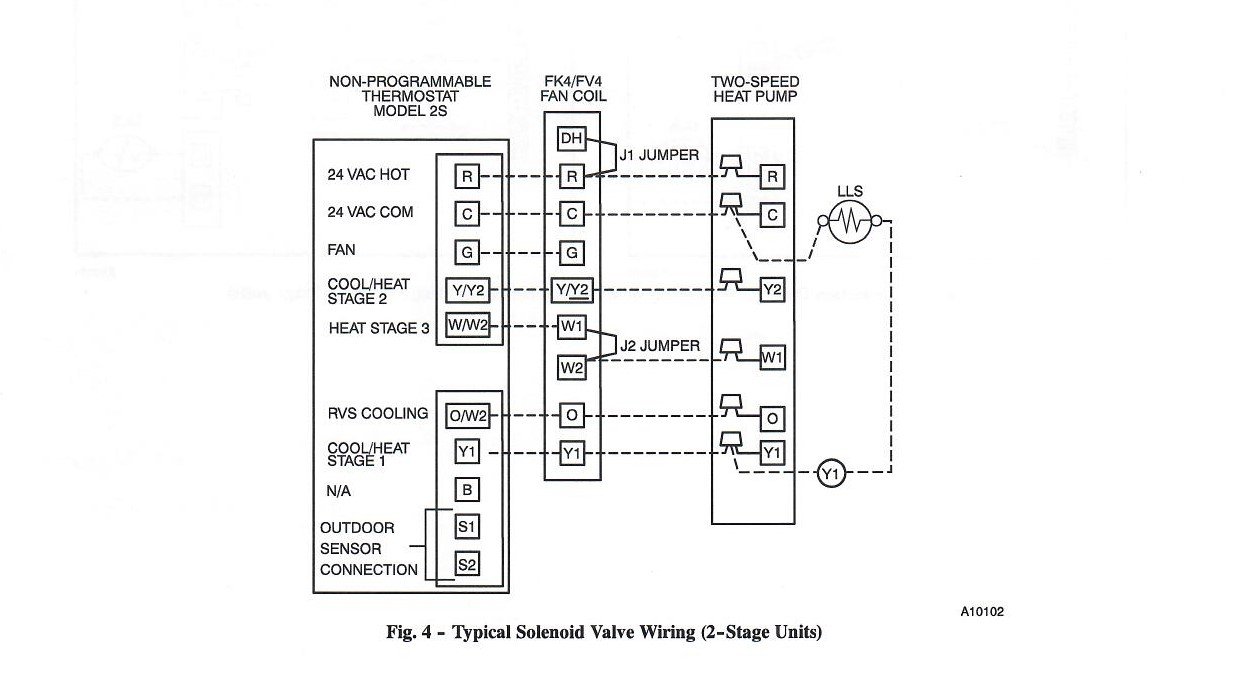

Wiring a liquid line solenoid valve will generally tap in with the thermostat’s call for the compressor. The valve should be wired into the Y (outdoor unit contactor) and C (common) terminals on single-stage equipment. For two-stage equipment, make sure the valve opens with a call for the first stage of heating or cooling (Y1). This prevents the valve from remaining closed during compressor operation.

Solenoid valves are incredibly simple in design and operation. Troubleshooting long line applications is also quite a simple task. Confirm that the coil is receiving its rated applied voltage when the system is energized, and then test temperature drop across the valve. A maximum of 3° difference is allowable. The valves are NC (normally closed), so if there is a temp drop across the valve body but no applied voltage during system operation, confirm your wiring.

Always make sure you are applying industry best practices when installing a solenoid valve. Remove the coil from the valve body before installation to prevent overheating. Use a heat absorption putty, spray, or wet rag on the valve body. Flow nitrogen while brazing, and install filter driers every time (oversized, if possible).

Long-line applications are few and far between in residential HVAC. But if you ever encounter a situation where you see a liquid line solenoid valve next to the outdoor unit, pay close attention to how that system is set up and any other added accessories that may have been installed. You may refer to the Residential Long-Line Application Guideline at any time.

—Kaleb Saleeby

P.S. – If you'd like to go back over the basics of a liquid line solenoid valve, check out this article.

Comments

Just a reminder to reinstall the solenoid coil to the valve body BEFORE applying voltage.

(Please don’t ask why I know this).

Also suggest the use of a troubleshooting magnet, available from our friends at TTT:

https://www.trutechtools.com/CPS-TLMKC18-Solenoid-Valve-Troubleshooting-Magnet-18mm?gclid=EAIaIQobChMIgOOY_Kj05wIVBb7ACh3adwNOEAQYAyABEgKqafD_BwE

Just a reminder to reinstall the solenoid coil to the valve body BEFORE applying voltage.

(Please don’t ask why I know this).

Also suggest the use of a troubleshooting magnet, available from our friends at TTT:

https://www.trutechtools.com/CPS-TLMKC18-Solenoid-Valve-Troubleshooting-Magnet-18mm?gclid=EAIaIQobChMIgOOY_Kj05wIVBb7ACh3adwNOEAQYAyABEgKqafD_BwE

Этот бот способен найти информацию о любом человеке .

Укажите имя, фамилию , чтобы получить сведения .

Система анализирует публичные данные и цифровые следы.

глаз бога бот

Информация обновляется мгновенно с фильтрацией мусора.

Оптимален для проверки партнёров перед важными решениями.

Конфиденциальность и актуальность информации — наш приоритет .

Этот бот способен найти информацию о любом человеке .

Укажите имя, фамилию , чтобы получить сведения .

Система анализирует публичные данные и цифровые следы.

глаз бога бот

Информация обновляется мгновенно с фильтрацией мусора.

Оптимален для проверки партнёров перед важными решениями.

Конфиденциальность и актуальность информации — наш приоритет .

Прямо здесь доступен сервис “Глаз Бога”, что проверить всю информацию по человеку по публичным данным.

Бот работает по номеру телефона, используя актуальные базы в Рунете. С его помощью осуществляется 5 бесплатных проверок и детальный анализ по имени.

Сервис актуален на август 2024 и поддерживает мультимедийные данные. Глаз Бога сможет узнать данные по госреестрам и предоставит информацию мгновенно.

глаз бога официальный бот

Это сервис — идеальное решение при поиске персон удаленно.

Прямо здесь доступен сервис “Глаз Бога”, что проверить всю информацию по человеку по публичным данным.

Бот работает по номеру телефона, используя актуальные базы в Рунете. С его помощью осуществляется 5 бесплатных проверок и детальный анализ по имени.

Сервис актуален на август 2024 и поддерживает мультимедийные данные. Глаз Бога сможет узнать данные по госреестрам и предоставит информацию мгновенно.

глаз бога официальный бот

Это сервис — идеальное решение при поиске персон удаленно.

Die Royal Oak 16202ST kombiniert ein 39-mm-Edelstahlgehäuse mit einem extraflachen Gehäuse von nur 8,1 mm Dicke.

Ihr Herzstück bildet das neue Kaliber 7121 mit 55 Stunden Gangreserve.

Der smaragdene Farbverlauf des Zifferblatts wird durch das Petite-Tapisserie-Muster und die Saphirglas-Abdeckung mit blendschutzbeschichteter Oberfläche betont.

Neben Stunden- und Minutenanzeige bietet die Uhr ein praktisches Datum bei Position 3.

Piguet Royal Oak 14790st damenuhren

Die bis 5 ATM geschützte Konstruktion macht sie alltagstauglich.

Das integrierte Edelstahlarmband mit verstellbarem Dornschließe und die oktogonale Lünette zitieren das ikonische Royal-Oak-Erbe aus den 1970er Jahren.

Als Teil der „Jumbo“-Kollektion verkörpert die 16202ST meisterliche Uhrmacherkunst mit einem Wertanlage für Sammler.

Die Royal Oak 16202ST kombiniert ein 39-mm-Edelstahlgehäuse mit einem extraflachen Gehäuse von nur 8,1 mm Dicke.

Ihr Herzstück bildet das neue Kaliber 7121 mit 55 Stunden Gangreserve.

Der smaragdene Farbverlauf des Zifferblatts wird durch das Petite-Tapisserie-Muster und die Saphirglas-Abdeckung mit blendschutzbeschichteter Oberfläche betont.

Neben Stunden- und Minutenanzeige bietet die Uhr ein praktisches Datum bei Position 3.

Piguet Royal Oak 14790st damenuhren

Die bis 5 ATM geschützte Konstruktion macht sie alltagstauglich.

Das integrierte Edelstahlarmband mit verstellbarem Dornschließe und die oktogonale Lünette zitieren das ikonische Royal-Oak-Erbe aus den 1970er Jahren.

Als Teil der „Jumbo“-Kollektion verkörpert die 16202ST meisterliche Uhrmacherkunst mit einem Wertanlage für Sammler.

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to far added agreeable from you! However, how could we communicate?

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to far added agreeable from you! However, how could we communicate?

On this platform, you can discover a great variety of online slots from leading developers.

Players can try out classic slots as well as modern video slots with stunning graphics and interactive gameplay.

Whether you’re a beginner or an experienced player, there’s always a slot to match your mood.

casino slots

Each title are available anytime and optimized for PCs and smartphones alike.

No download is required, so you can get started without hassle.

Site navigation is easy to use, making it convenient to find your favorite slot.

Sign up today, and discover the world of online slots!

On this platform, you can discover a great variety of online slots from leading developers.

Players can try out classic slots as well as modern video slots with stunning graphics and interactive gameplay.

Whether you’re a beginner or an experienced player, there’s always a slot to match your mood.

casino slots

Each title are available anytime and optimized for PCs and smartphones alike.

No download is required, so you can get started without hassle.

Site navigation is easy to use, making it convenient to find your favorite slot.

Sign up today, and discover the world of online slots!

To leave a comment, you need to log in.

Log In