BACK

C stands for “Common Mistake”

C stands for “Common Mistake”

Universal Condenser Fan Wiring Options

Universal Condenser Fan Wiring Options

Realistic Summer Triage Strategies

Realistic Summer Triage Strategies

Capacitor Testing and Replacement Procedure

Capacitor Testing and Replacement Procedure

Troubleshooting Inverter Boards

Troubleshooting Inverter Boards

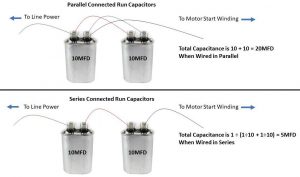

Capacitors – Series and Parallel

Capacitors – Series and Parallel

Testing Run Capacitors the Smart (and Easy) Way

Testing Run Capacitors the Smart (and Easy) Way

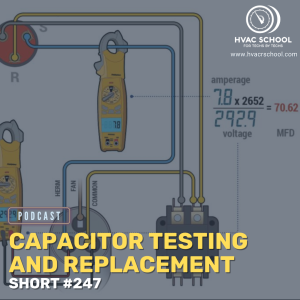

Capacitor Testing and Replacement – Short #247

Capacitor Testing and Replacement – Short #247

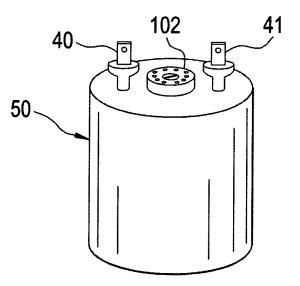

Intro to The Sigma Capacitor

Intro to The Sigma Capacitor

Q&A – Circuit Board Troubleshooting – Short #230

Q&A – Circuit Board Troubleshooting – Short #230

Farads, Micro and Pico – Short #180

Farads, Micro and Pico – Short #180

High Voltage A/C Electrical Class

High Voltage A/C Electrical Class

#capacitor

Tech Tips:

You have seen the C terminal on a dual run capacitor before. You have also seen the C terminal on a compressor. It stands to reason that they would both connect together, right? They don't connect, and they aren't even related, at least not in the way you think. In both cases, the C denotes […]

Read more

Assessing the Situation It is fairly common for a service technician to come across a failed condenser fan motor in the field. It doesn’t matter if we are talking about really old or fairly new equipment—condenser fan motors sometimes fail. The issue is deciding whether to use an OEM (Original Equipment Manufacturer) or a universal […]

Read more

This tech tip is a companion piece to a recent podcast with Kevin Hart from HAVEN. We’ve already had some record-breaking heat here in Florida, and that’s translated to an overwhelming number of calls. We know our HVAC brethren in other areas have been working their tails off all the same. Going without air conditioning […]

Read more

❶ Understand What a Run Capacitor Does The run capacitor provides continuous phase-shifted current to the motor start winding, allowing the motor to run: With the design efficiency In the right direction With the appropriate torque With near “unity” power factor (power factor near 1.0) If the run capacitor is failed, the motor often won't […]

Read more

Let's talk about the magic that is inverters and how to test the boards that drive this technology. Inverters play an extremely important role in household appliances, industrial machinery, and the rising popularity of household HVAC systems. Inverters consist of a wide variety of electronic circuitry, and there are many situations in which they need […]

Read more

Knowing how to combine capacitors in series and parallel properly is a great practical field skill to employ when you need to get a customer up and running, but you don't have the exact size. Increasing in size is easy. Just connect in parallel and add the two sizes together. For example, if you needed […]

Read more

When testing a run capacitor, many techs pull the leads off and use the capacitance setting on their meter to test the capacitor. On a system that is not running, there isn't anything wrong with this test. However, when you are CONSTANTLY checking capacitors as a matter of regular testing and maintenance, that extra step […]

Read moreVideos:

Podcasts:

In this short podcast episode, Bryan goes through the process of testing and replacing a run capacitor. Run capacitors provide continuous phase-shifted current to the start winding, allowing the motor to run in the right direction and with the appropriate amount of torque. These capacitors are needed in most of the single-phase PSC motors […]

Read more

Sharon Goepferich from Cool Air Products joins the podcast to discuss cutting-edge capacitor technology and innovative HVAC solutions in an introduction to the Sigma capacitor. Sharon brings a decade of industry experience, having worked extensively with capacitors and HVAC components while traveling across the country to educate technicians and contractors. The conversation begins with […]

Read more

In this short Q&A podcast episode, Bryan answers a listener-submitted question about circuit board troubleshooting: is there a quick way to learn how to check circuit boards, and if so, where are those resources? A circuit board is a bunch of components put together on a printed circuit board (PCB). There isn't a lot […]

Read more

In this short episode, Bryan explains the fundamentals of capacitance, focusing on the unit of measure: farads, including micro and pico. Farads are named after scientist Michael Faraday and measure capacitance; one farad represents the capacitance of a capacitor in which one coulomb of charge causes a potential difference of one volt across the […]

Read more

This podcast is a high voltage A/C electrical class that Bryan gave to some of the Kalos apprentices. The high voltage journey begins with basic electrical theory. Basically, a difference in charge is needed for electrons to move and generate power. Motors, which are inductive loads, are the greatest users of power that we will […]

Read more