BACK

Ramping Your Team Up for CO2

Ramping Your Team Up for CO2

What is “Cascade” Refrigeration?

What is “Cascade” Refrigeration?

CO2 Booster Systems (Codenamed CO2 is Interesting and Weird)

CO2 Booster Systems (Codenamed CO2 is Interesting and Weird)

How Do You Ramp Up Your Team to Effectively Service and Support CO2 Applications?

How Do You Ramp Up Your Team to Effectively Service and Support CO2 Applications?

CO2 Introduction Podcast & Resources

CO2 Introduction Podcast & Resources

The Fundamentals of CO2 Refrigeration

The Fundamentals of CO2 Refrigeration

#co2

Tech Tips:

This tech tip is based on a podcast with Andre Patenaude from Copeland. You can listen to that podcast episode HERE, and we encourage you to check out some of the resources at the end of this tech tip—whether you’re all in on ramping your team up for CO2 or just CO2-curious. Carbon dioxide (CO2) […]

Read more

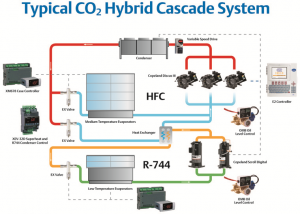

Photo Courtesy of Emerson What is Cascade refrigeration? “Cascade refrigeration” is a term you will hear more and more over the coming years, and while some of the systems may be very complex, the concept is actually pretty simple. Some refrigerants are well-suited for high and medium-temperature applications, and some are better suited for lower-temp […]

Read more

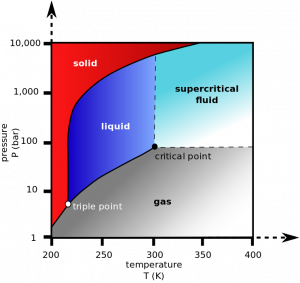

Illustration Courtesy of Emerson CO2 is a pretty nice refrigerant. It has zero ODP (ozone depletion potential) and a GWP (global warming potential) of 1. CO2 has been used as a refrigerant almost from the very beginning of refrigerants, and it's been making a big comeback in market refrigeration (especially in colder climates). CO2 […]

Read moreVideos:

Podcasts:

In this informative episode, Bryan Orr speaks with Andre Patenaude from Copeland about CO2 refrigeration systems. They dive deep into the unique characteristics and challenges of working with CO2 as a refrigerant, providing valuable insights for HVAC and refrigeration professionals looking to expand their knowledge in this growing field. Andre explains the reasons behind […]

Read more

In this episode of the podcast, Bryan talks with Andre Patenaude from Emerson about CO2 refrigeration, and transcritical booster systems. Modern CO2 systems are efficient and effective due to their electrical controls and components, including case and high-pressure controls. Carbon dioxide (CO2) is a good refrigerant to address global climate change. From a sustainability standpoint, […]

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more