BACK

Introduction to SORIT Valves

Introduction to SORIT Valves

EPR valves 101

EPR valves 101

Q&A – EPR and Pressure Limiting Valves w/ Matthew Taylor

Q&A – EPR and Pressure Limiting Valves w/ Matthew Taylor

#EPR

Tech Tips:

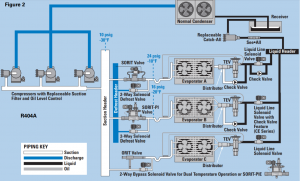

Photo Courtesy of Parker/Sporlan There are many brands and styles of evaporator pressure regulating valves (EPR), but none as common as the Parker/Sporlan SORIT and ORIT valves. The diagram above clearly shows some of the common applications. An EPR or “hold back” valve maintains a set suction line pressure and, therefore, coil temperature. That is […]

Read more

I don't do much in the way of “rack” refrigeration. However, I recently had a conversation with experienced rack refrigeration tech Jeremy Smith, and he got me thinking about EPR valves. I've heard EPR (evaporator pressure regulator) valves called suction regulators or hold back valves. In essence, they hold back against the suction line to […]

Read moreVideos:

Podcasts:

In this episode, Matthew Taylor joins the podcast to dive deep into the world of pressure-limiting valves and regulators used in refrigeration and air conditioning systems. They explore the intricacies of Maximum Operating Pressure (MOP) expansion valves, Evaporator Pressure Regulators (EPR), and Crankcase Pressure Regulators (CPR), discussing their functions, applications, and differences. The conversation […]

Read more