BACK

3 Ways to Reduce Compression Ratio in a Heat Pump

3 Ways to Reduce Compression Ratio in a Heat Pump

Refrigerant Charging Basics For Air Conditioning & Heat Pump Systems

Refrigerant Charging Basics For Air Conditioning & Heat Pump Systems

Understand Heat Pumps

Understand Heat Pumps

Heat Pump Defrost Troubleshooting Tips

Heat Pump Defrost Troubleshooting Tips

Good COP – Bad COP

Good COP – Bad COP

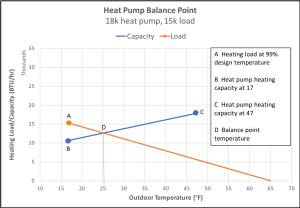

Thermal Balance Point

Thermal Balance Point

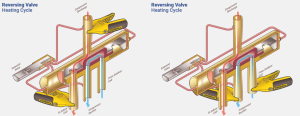

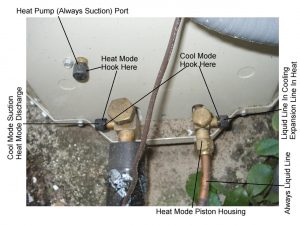

Diagnosing a Reversing Valve

Diagnosing a Reversing Valve

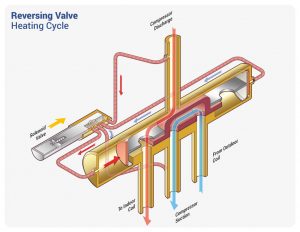

How a Heat Pump Reversing Valve Works

How a Heat Pump Reversing Valve Works

Checking the Charge on a Heat Pump in the Winter

Checking the Charge on a Heat Pump in the Winter

Heat Pumps / Comfort and Electrification w/ Copeland

Heat Pumps / Comfort and Electrification w/ Copeland

How to Predict Air Flow Issues in the Sales Process

How to Predict Air Flow Issues in the Sales Process

Q&A – System Won’t Dehumidify? – Short #214

Q&A – System Won’t Dehumidify? – Short #214

Heat Pump COP and Low Temp Lock Out

Heat Pump COP and Low Temp Lock Out

When to Switch to Emergency Heat? – Short #190

When to Switch to Emergency Heat? – Short #190

What’s Different About Pool Heaters w/ Bert

What’s Different About Pool Heaters w/ Bert

Checking a Heat Pump in Heat Mode – Short #178

Checking a Heat Pump in Heat Mode – Short #178

Heat Pumps, Reversing Valves, and Defrost Podcast

Heat Pumps, Reversing Valves, and Defrost Podcast

The Great Heat Pump Revolt of 2026 and How to Avoid It

The Great Heat Pump Revolt of 2026 and How to Avoid It

Electrification in HVAC: An Update

Electrification in HVAC: An Update

Understanding Dual Fuel

Understanding Dual Fuel

#heat pump

Tech Tips:

We’ve talked about compression ratio a lot over the years. Compression ratio is the number you get when you divide the absolute head pressure (PSIG + 14.7) by the absolute suction pressure (PSIG + 14.7). It measures the efficiency of a compressor, and lower numbers indicate that the compressor is moving more refrigerant while consuming […]

Read more

Before I start on this one… At HVAC School, we focus on a wide range of topics. Many of them are very basic. My experience as a trainer for over 20 years has taught me that no matter what I assume others SHOULD know, it doesn't change the fact that they often do not. This […]

Read more

My goal in this tech tip is to help those who struggle to understand heat pumps get their heads around them as quickly as possible and understand some of the things a tech needs to know about them. The basic idea of a heat pump is to use the compression refrigeration cycle to move heat […]

Read more

We’ve entered that season of service calls for “smoking heat pumps,” and I figured now is as good a time as any to share a few quick tips for troubleshooting defrost. Of course, the “smoking heat pump” calls can be solved over the phone with a quick explanation of normal defrost conditions—as can the service […]

Read more

There has been a lot of advice being tossed around by contractors and builders about the best time to use the emergency heat feature on an all-electric heat pump system. The answer is never! That was easy. Next article… In all seriousness, “Emergency Heat” should be used as described, ONLY during an emergency. I guess I should […]

Read more

Thermal balance point is a concept that is going to start mattering a lot more in years to come as more and more homeowners become interested in electrification. In almost all cases, the heat load for a house is larger than the cooling load; this is true even where I live in Dallas, Texas. Why […]

Read more

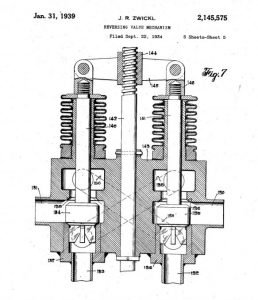

Introduction Replacing a reversing valve is either every technician’s dream or nightmare. The sheer amount of brazing involved in confined spaces will inspire either delight or nightmares about the upcoming valve replacement. Fortunately, these emotional highs and lows are uncommon because we don’t diagnose and replace bad reversing valves very often. That itself poses a […]

Read more

If you don’t have a gas furnace or fireplace in your home, your unit’s reversing valve is probably your best friend during the winter months. As their name suggests, reversing valves reverse the refrigerant flow to send the hot, compressed vapor to the indoor coil instead of the outdoor coil. The system releases heat into […]

Read more

When you ask many people nowadays how to check the charge on a heat pump during low outdoor temps, they will say that you need to “weigh in and weigh out” the charge. While this may be an effective method, it isn't always practical. Now, if you are making a refrigerant circuit repair, weighing out […]

Read moreVideos:

Podcasts:

In this informative episode, Josh Souders from Copeland joins Bryan to dive deep into heat pump technology, discussing everything from basic operations to advanced features in cold climate applications. The conversation begins with a fundamental explanation of how heat pumps work, describing them as essentially air conditioners with a reversing valve that allows them […]

Read more

Chris Hughes and Steve Rogers from The Energy Conservatory discuss TEC's TrueFlow technology and its crucial role in predicting airflow issues in the sales process, particularly for heat pump retrofits. They explain how the TrueFlow app helps contractors accurately measure both static pressure and airflow in existing systems, enabling them to predict whether proposed […]

Read more

In this short podcast episode, Bryan answers a listener-submitted question about an HVAC system that won't dehumidify. This question was submitted by a homeowner with a Carrier heat pump with an attic air handler that cools but won't dehumidify on the hottest days of summer. One of the past companies that serviced the system […]

Read more

This episode of the HVAC School Live Stream covers the key concepts around heat pump efficiency and understanding the coefficient of performance (COP). Eric Kaiser from TruTech Tools and Jim Fultz from White-Rodgers provide valuable insights into how heat pumps operate and how to optimize their performance, especially in colder weather conditions. The discussion […]

Read more

In this short podcast episode, Bryan talks about when to switch to emergency heat. He talks about coefficient of performance (COP) and how it's a deciding factor when to run emergency heat, which is when a system ONLY runs the backup heat; it doesn't use it as supplementary heat. When we have a heat […]

Read more

In this podcast, Bryan Orr and Bert discuss various aspects of pool heaters, focusing on issues that make them different from typical HVAC systems. They cover the basics of pool heaters – the main types (heat pumps and gas heaters) and how they operate similarly or differently from things HVAC techs work on regularly. […]

Read more

In this short podcast, Bryan talks about checking the charge of a heat pump in heat mode. This skill will become more critical as ambient temperatures get cooler. The most reliable way to check and set the charge regardless of operating mode and season is to weigh the charge. This method is most practical […]

Read more

In this episode of HVAC School, Bryan covers the basics of heat pumps. Heat pumps are common technologies in Florida. They reverse the sequence of the typical refrigerant circuit: the indoor coil can become the condenser, and the outdoor coil can become the evaporator. Heat pumps can achieve that transition via a reversing valve, which […]

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more