BACK

Under Pressure

Under Pressure

Finishing Trade School? Some Things you Need to Know

Finishing Trade School? Some Things you Need to Know

Using Power Factor to Check Capacitors Under Load

Using Power Factor to Check Capacitors Under Load

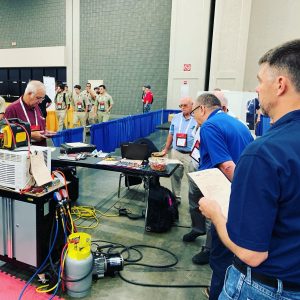

Getting Involved In HVAC/R Education

Getting Involved In HVAC/R Education

#hvac school

Tech Tips:

A few weeks ago, I was hired to consult on a multi-family new construction project. The building was already framed, and the ducts were roughed in. The owner of the building was concerned with the quality of the ductwork. He noticed that the HVAC company was not following the mechanical engineer's plans. This was my […]

Read more

So, I hear you're just finishing trade school. Well done. You chose to take an excellent path, and now your journey is just beginning. How this will go is really up to you, and that's a good thing! You aren't going to be forced in one direction or another; you get to choose. Let's talk […]

Read more

Capacitors are traditionally tested with a capacitance meter (commonly found as a function within a multimeter), with the component taken entirely out of the circuit. “Bench testing,” as this method is referred to, is hands-down the safest method of checking capacitance in microfarads. All other methods require the capacitor to be wired into the circuit […]

Read more

Because the name of the website is HVAC School, I get a lot of people who assume we either: A) Have a physical location B) Sell online courses You are probably aware by now that we do neither of those things. We are a free learning resource for anyone looking to improve their professional skills […]

Read more