BACK

It’s All Relative… Humidity

It’s All Relative… Humidity

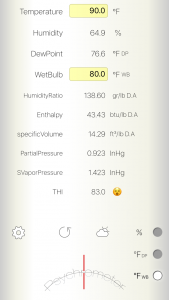

Wet-Bulb and Dry-Bulb Temps in HVAC Service

Wet-Bulb and Dry-Bulb Temps in HVAC Service

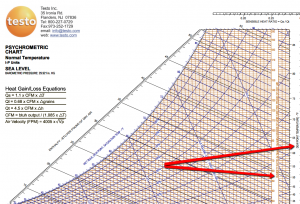

Understand Dew Point and Absolute Moisture, The Right Side of the Psych Chart

Understand Dew Point and Absolute Moisture, The Right Side of the Psych Chart

Coil SHR, Ventilation, and Bypass Factor – Advanced Psychrometrics Part 2

Coil SHR, Ventilation, and Bypass Factor – Advanced Psychrometrics Part 2

Room Sensible Heat & CFM – Advanced Psychrometrics Part 1

Room Sensible Heat & CFM – Advanced Psychrometrics Part 1

Psychrometrics Without Tears

Psychrometrics Without Tears

#Psychrometrics

Tech Tips:

Florida’s got a lot of great qualities: some pretty neat wildlife, beaches all around, and theme parks. On the flip side, Florida also has hurricanes and a lot of humidity. As much of a pain as it might be for residents and contractors alike, humidity is one of my favorite topics. We see relative humidity […]

Read more

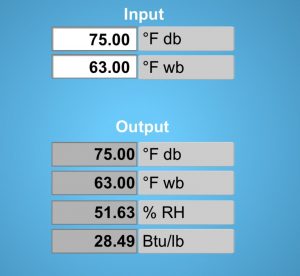

This tech tip is based on a segment of a recent podcast episode with Joey Henderson, “Using Refrigerant Troubleshooting Charts w/ Joey Henderson.” You can listen to that podcast HERE. Credit: efficientcomfort.net If you’ve seen a superheat charging chart (like the one above), you’ll notice that you need to take the dry-bulb (DB) temperature entering […]

Read more

Let's first state the obvious. Most techs are intimidated by psychrometric charts and Mollier diagrams. We JUST ARE. While there are some pretty complicated formulas that back up these diagrams, using them isn't that big of a deal once you understand the different elements and then focus on one at a time. BUT WHY DO YOU […]

Read more

This is the second article in a three-part series where we explore advanced psychrometrics. The source material for each of the articles in this series is ACCA Manual P Sections 3, 4, and 5. This article is based on information found in Section 4. If you followed the previous advanced psychrometrics article, you now know […]

Read more

This is the first of a three-part series of articles that will dive deep into advanced psychrometrics. The source material for each of these articles may be found in ACCA Manual P Sections 3, 4, and 5. This article is based on information found in Section 3. Psychrometrics is the study of the physical and […]

Read moreVideos:

Events:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more