BACK

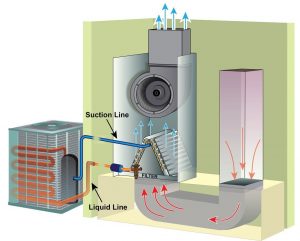

Impacts of Decreasing Evaporator Airflow

Impacts of Decreasing Evaporator Airflow

#split

Tech Tips:

Airflow, airflow, airflow… When we set up and commission comfort cooling and heating systems, we need to pay more attention to airflow before worrying about the fancy controls or the refrigerant circuit. One way to do that is by checking out Bill Spohn's Airflow 101 webinar on ESCO Group's learning network, which you can access […]

Read more