Get Tech Tips

Subscribe to free tech tips.

HVAC Ghosts of Christmas Past, Present, and Future

There have been many adaptations of A Christmas Carol over the years, but it all started with a novella written by Charles Dickens in the 1840s. It was early in the Victorian Era, fresh off the heels of the Industrial Revolution. The British were reflecting on past Christmas traditions, like caroling, and exploring new ones with their newfound economic prosperity, sending Christmas cards and decorating trees. They were at a point where they could choose how to spread the Christmas spirit. Dickens took this opportunity to explore the turning point of a man named Ebenezer Scrooge: to continue down the same ruinous path as his dead business partner or leave behind his miserly ways and embrace the spirit of giving.

HVAC, too, always seems to find itself in major changes—sometimes because the government tells us we have to, and other times because broader societal trends influence the trades. The industry often finds itself at a crossroads, whether in terms of adopting a new refrigerant, new business practices, or new technology in general. Sometimes, it seems like we have no choice but to adapt, but sometimes, we do have the power to recognize where a path will lead and make a change for the better.

No, this isn’t my latest hairbrained scheme to get as many people aboard the R-290 Monobloc Heat Recovery Chiller Express as I can. I want us to think about where we’ve come from as an industry and avoid becoming a ghost of our former selves, bound by the chains of private equity and a technological race to the bottom. And who better to show us than the Ghosts of HVAC Past, Present, and Future (or HVAC Yet to Come, if you want to get fancy)?

The Ghost of HVAC Past

The Ghost of HVAC Past is a curious creature. Some say it looks like a 7-SEER split air conditioner that dehumidifies like a champ. Others have reported sightings of a mercury thermostat with the ol’ reliable heat anticipator. In any case, it looks ancient and REALLY good for its age.

The Old-Timer Ethos to Remember

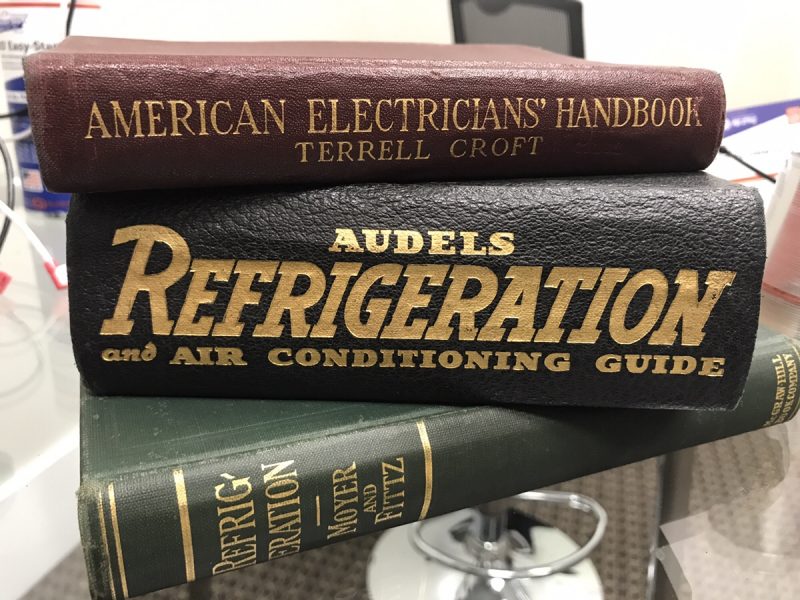

This ghost is familiar with the old-timer ethos forged in a time before A2Ls, EEVs, and communicating thingamajigs: beer can cold, RTFM from a heavily processed dead tree, venting refrigerant, and never flowing nitrogen while brazing. Old-timers are a different breed, still around in some circles but becoming scarce as sunny beaches and pensions call their names. They have sharp mechanical intuition and know how to make things work using just their hands, brains, and a little grit. Online resources were scarce (if they existed at all), and there was certainly no ChatGPT.

HVAC technicians of the past knew how to be resourceful and rapidly gained experience by putting their hands on systems. They put in reps and had many chances to hone their craftsmanship. The emphasis on hands-on work made it easy for many of them to become really dang good at their jobs.

… But Skills Were a Product of the Times

Trades knowledge in the HVAC past was highly practical, and the techs and installers knew how to do things very well. However, that knowledge was also specifically tailored to the systems of the times. There was a limited understanding of the chemistry that informs many of our current best practices.

There was less need to pull deep vacuums or flow nitrogen while brazing back in the day because we used chlorine-based refrigerants (CFCs and HCFCs). CFCs and HCFCs used mineral oil, which didn’t attract water, turn to acid, or scrub cupric oxide off the tubing walls and gunk up filter-driers and valve screens.

As the industry has evolved, many of the practices that were fine twenty, thirty years ago are no longer so. Flowing nitrogen while brazing and pulling a deep vacuum is a MUST because of the POE oil used by HFCs and HFO blends. Beer can cold no longer cuts it for superheat (and really never did, but who doesn’t still grab the suction line?).

Simply knowing to feel for a certain temperature is no longer good enough; we need to know how to use P-T charts and understand what superheat and subcooling really signify to avoid making mistakes while charging (or blaming a perfectly fine TXV).

Field practices must be supported by theory and an understanding of why. Getting in the reps helps, but it’s not enough to understand how HVAC systems work and give customers the best possible comfort.

The Ghost of HVAC Present

The Ghost of HVAC Present looks like a jolly giant VRF system. It has at least three heads of varying capacities tied to a single outdoor unit. Some might find it intimidating and mistake it for a monster. Others make friends with it quite easily. (*Everybody collectively looks at Roman Baugh.*)

Tools and Tech

The tools and HVAC equipment have evolved a lot in the last decade or two.

Nowadays, we don’t just have HVAC systems that turn on and off; we have compressors that can modulate to meet different load conditions (whether we set them up to do it effectively in humid climates is another matter entirely). We have fan speeds that can change. We have controllers that send signals between indoor and outdoor units to adjust their performance. Heck, we have heat pumps that work very well in Maine and even Norway, thanks to improved system and equipment design.

We also have better tools: digital tools with fine resolution, probes that let us see refrigerant pressure and temperature readings on our phones 20 feet away, and apps that point out the red flags in our measurements. HVAC technicians are no longer just limited to installing and fixing boxes. They can become building engineers with access to the right resources (and excellent educators) and widely available blower doors, duct leakage testers, and precision manometers.

We can optimize comfort in ways that most HVAC technicians in the past might never have thought. Equipment has gotten better at load matching, we have many great industry resources (from organizations like ACCA and NCI to individual educators like Craig Migliaccio and Ty Branaman), and we have information available at our fingertips.

However, all these improvements also pave the way for vices to emerge…

The Rise of a Sales-Driven Culture

First of all, sales aren’t bad. Wanting to earn money to secure a better life for yourself and your family is perfectly fine. What is bad is sacrificing integrity in the pursuit of sales.

We can use data to drive sales; if a customer has comfort problems and requests a Manual J load calculation, we can sell them a properly sized system. We make a sale to feed our families (or pay our employees so they can feed theirs), and the customer gets better comfort in return.

However, the issue is when people don’t understand how to solve problems and push “solutions” that do very little to help and may actually worsen the customer’s situation. Selling a bigger HVAC unit without offering to investigate the structure or perform a load calculation when a customer complains about a muggy home is a prime example; there could be duct or building leakage making the house feel muggy, and a larger unit is just going to have shorter runtimes (and reduced dehumidification), which makes the problem worse.

And what does that say about the industry? One bad actor (or poorly informed HVAC practitioner) is just going to inform the opinions of their dissatisfied customers. But when we have several people (or private equity buyers) who put the almighty dollar above thorough diagnostics, education, and genuine customer care, there comes a point where the general public can’t trust the industry.

There are many great people out there who do things the right way and educate others to commission and diagnose HVAC systems properly. But when workmanship cheapens across the board, in part accelerated by the pursuit of profit (or debt repayment) over best practices, things start to look bleak.

The Ghost of HVAC Yet to Come

I think this is the part where a hooded ghost that doesn’t talk points at a tombstone with something like a gauge manifold on it. That’s a bit melodramatic, but there is indeed a grave consequence to workmanship and education taking a backseat to sales.

Private Equity Buyouts

In recent years, we’ve seen more HVAC businesses get bought out by private equity firms. In fact, it’s such a well-known issue in the industry that Forbes reported on it last year. These buyouts often cause those firms to go into debt in the short term while they hold out for greater long-term profits—how do they pay off that debt quicker? Raising prices, pushing sales over repairs, and cutting corners. And why invest in the technicians’ training when it comes with an upfront cost? Why teach them to repair when a replacement is much more lucrative?

Those moves only accelerate the race to the bottom in terms of education, skill, and craftsmanship. When technicians don’t have a company that’s willing to invest in their training, they don’t have a chance at doing their jobs well. Sure, some technicians could take it upon themselves to find those resources themselves, but therein lies another rising problem…

Dependency on Tech and AI

AI has become a huge part of the industry within the last couple of years, and it has many good uses. AI is great at detecting patterns, so it’s great when we apply it to commercial controls and manage runtimes for energy efficiency, assist with troubleshooting, and more. On the business side, it can help organize information and automate drumbeat tasks, to some extent, which gives us more time to do the tasks that make a difference (and that we enjoy).

However, it is NOT good at teaching hands-on skills or solving very specific, niche problems—and many people use it to get quick and easy answers or solutions. How can you expect to learn how to dial in superheat with pressure probes by reading an amalgamation of text from a mix of free educational resources, forums, and who knows where else? How are you supposed to learn how to troubleshoot a commercial system with advanced controls—which are often highly customized and for which there is very little publicly available literature—by asking ChatGPT to spit out an answer?

Unfortunately, a good chunk of the upcoming generation of workers has already used AI heavily to write essays and solve problems in school—not just to organize information but to outsource the creative problem-solving and critical thinking parts as well. Those two things are non-negotiable for good HVAC techs, and we reinforce them each time when we put our hands on systems and seek out the bulletins and manuals we specifically need to solve a problem. And what happens when fewer people understand the systems on the market and can’t write useful product literature to assist with problem-solving?

Fewer people have what it takes to do the work.

A Loss of Pride, Identity, and Quality

When HVAC companies become investments rather than service providers and critical thinking is sacrificed for a quick and easy solution in all segments of the industry, what’s left to take pride in? Service, diagnostics, manufacturing, and tech support all suffer from this cheapening while prices continue to climb. Customers take out their frustrations on techs, even when the issue is way above them. Does anyone want to do a job they can’t take pride in?

If we continue down this path, then in fifty-some years (if it even takes that long), there may be no such thing as an expert—just dull parts-changers who do what they can to get by. In this future, there is no artistry in the install anymore, as the systems are no longer built or maintained to last. There is no tech support question that’s worthy of human attention and can’t be answered by a chatbot that may or may not give you the answer you’re looking for. There’s no reason to find the same professional pride in a blue-collar work ethic.

What satisfaction is there in solving a problem when everything is “easy” and doesn’t last? What kind of life is that, and who would willingly be part of it?

Nevertheless, those questions sink, collapse, and dwindle down into bedposts, and when we awaken, we realize…

The Time Before Us Is Our Own

Luckily for us, the grim image of HVAC yet to come is the HVAC that may be, not the HVAC that will be. Just like Scrooge on Christmas morning, we know there’s still time to choose a better future for the trade.

Treat HVAC Businesses as a Way of Life, Not an Investment

While HVAC businesses are a means of making money and providing for our families, they also provide for communities. Would you rather be the one doing a service for your neighbors, or would you rather have a large company do it and provide substandard service?

When technicians are the ones who own their businesses, they are connected to the community, and that’s what humans are wired for anyway—connection. We do need money to survive, but isn’t there something to be said about earning money while providing value to the community? Particularly when the alternative is walking away with a bunch of money from a private equity investor who will jack up prices and push sales over workmanship?

A lot of industry leaders and educators own their HVAC businesses and have specialized in some area of building performance or consultation. That’s their path to continuous improvement, and it would be great for more people to follow in their footsteps: master fundamentals, and then open up your service offerings. This is the way to upward mobility within companies: give apprentices a solid foothold and then commit to education to build their skills and grow into specialized roles that suit them.

Maybe those techs will stay with your company and train the new blood, or maybe they’ll work for another company (or start their own!) and bring their skills with them. No matter where they end up, they’ve been trained with the commitment to craftsmanship and best practices that our industry thrives on.

Get Young People Interested in the Trades

And then there’s the question of where we get apprentices to train in the ways of craftsmanship and best practices. Look no further than the upcoming generation.

Many young people simply aren’t aware of opportunities in the skilled trades—or the joy of working with their hands. Shop class is nowhere near as prevalent as it once was, so students are not getting the exposure to hands-on crafting and problem-solving that they once had.

Groups like the GRIT Foundation are working to change that. We’ve worked with contractors around the country to run day camps where middle and high schoolers receive a set of plans for an assembly they need to build using carpentry, plumbing, and electrical skills. The mentors who guide the students don’t answer questions directly; we train them to use the Socratic method to get students to think about things like why we use PVC for some pipes and copper for others, why and when we use different fastener types, and why electrical circuits have a switch, load, and power supply. The purpose is to get children to feel the joy of working with their hands and solving a puzzle in a safe, controlled environment while they build their skills.

When we get people excited about opportunities in the trades (and what their hands and minds are REALLY capable of) and make sure HVAC businesses are run by actual tradespeople, the future looks a lot brighter. The industry stays sustainable; although prices do depend on economic trends, they can at least reflect the quality of our labor more than massive private equity debts. And tomorrow’s future looks brighter when we have the professional pride to evangelize the value of the trades with each and every service call, GRIT Camp, career day, or wherever else.

Of course, that’s pretty idealistic. But if enough people reflect on who we are and what people really value, just like Ebenezer Scrooge, we can stand together to create a better future that is enhanced by technology and the times but not totally reliant on it. We must remember that blue-collar ethos, pair it with the technology of today, and consider tomorrow’s apprentices.

Merry Christmas. In the words of Tiny Tim, who indeed lived when Scrooge had his change of heart: God bless us, every one.

Comments

To leave a comment, you need to log in.

Log In