Get Tech Tips

Subscribe to free tech tips.

Set Inverter Technology Up for Success in Humid Climates

This tech tip about humidity control, particularly as it relates to VRF systems and others that use inverter technology, is a companion piece to a podcast episode with Roman Baugh. You can listen to that podcast episode HERE.

Those of you who work in humid climates and install or repair ductless systems are probably well aware of a common issue they face: efficient as they are, they’re just not that good at removing humidity. There are several misconceptions about systems that use inverter technology, including ductless mini-splits and VRF systems, and their ability to adapt their performance to their environment.

In this tech tip, we’ll cover some common misconceptions about inverter-driven system performance in humid climates. Along the way, we’ll cover the ways in which they may (or may not) be able to dehumidify effectively and share some practical ways to support them in humid climates.

Main Factors of Equipment-Based Dehumidification

First, let’s look at the relationship between HVAC equipment and indoor humidity in general. This relationship is influenced by many factors. Several of these are external, particularly related to the building envelope, but the main three that are directly related to the equipment are:

- Runtime

- Surface condensation

- Coil temperature

Generally, Longer Runtimes = Better Dehumidification

We’ve discussed short-cycling quite a bit on the podcast and in tech tips, and it’s not good for several reasons (including reducing the compressor life). From a dehumidification standpoint, we don’t like short-cycling because it keeps the unit from running long enough to get the coil temperature to drop well below the dew point.

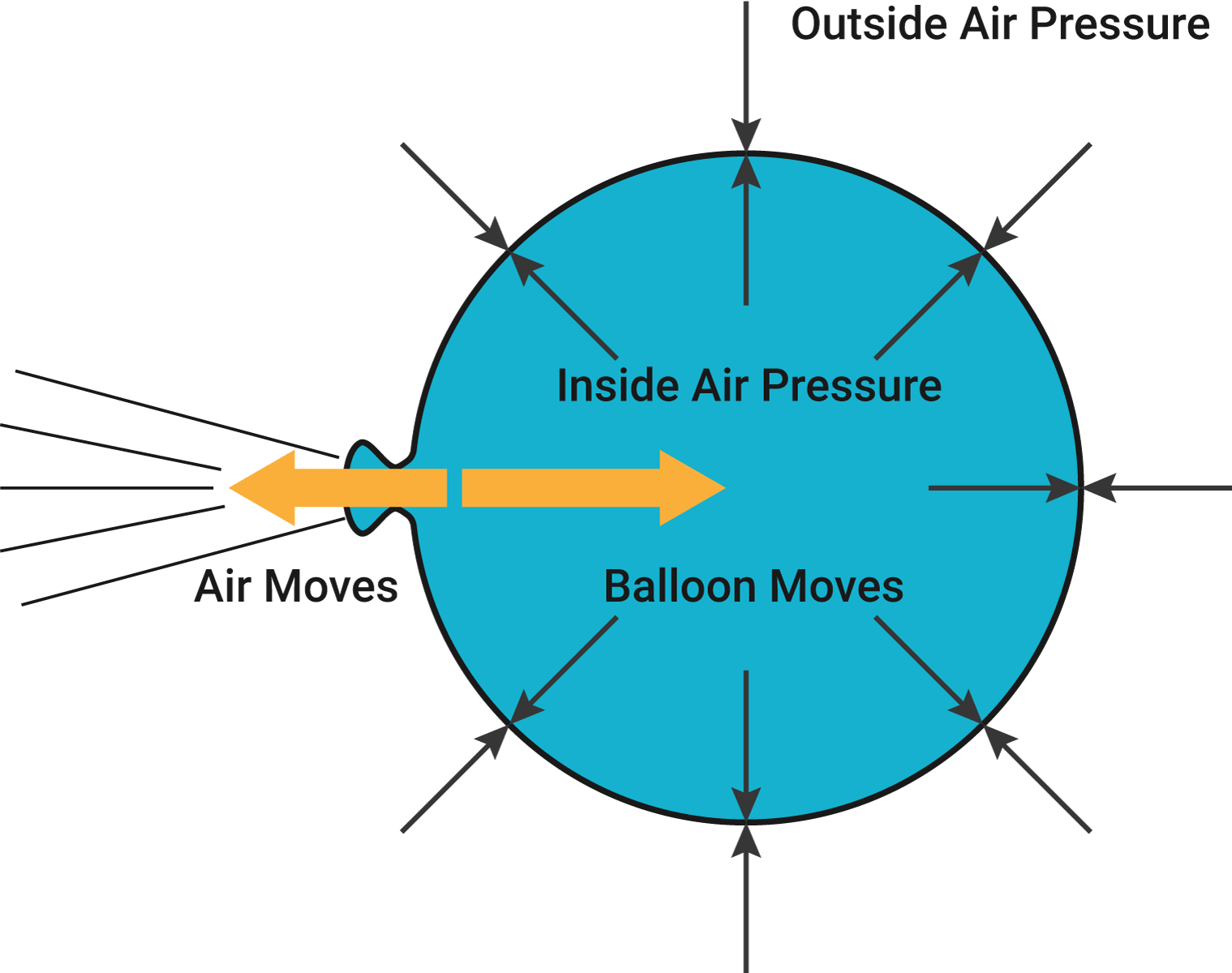

When a surface (in this case, the coil) is below the dew point, the air around it cools and can no longer support the amount of water vapor moving with it. That water vapor condenses to liquid water and deposits on the surface, almost like localized rain.

Condensation We DON’T Want: Sweating Vents

One of the biggest problems we come across in humid climates is when this condensation happens on ducts and vents (surface condensation or “sweating”). After passing over a cold coil and moving through the ductwork, the air that comes out of the supply registers (or diffusers, depending on design) is usually around 55°F. That cool air will reduce the temperature of the vent’s surface, and since the dew points are usually above 55°F in the summers and shoulder seasons of humid climates, it’s common for moisture to condensate on the cool vent.

A common band-aid fix is to increase the equipment’s fan speed and make it so that the vent’s temperature doesn’t drop as much. Unfortunately, that fix focuses on the vent’s surface temperature at the cost of raising the coil temperature, resulting in less dehumidification overall. Sealing the area around the vent to prevent moist attic air from escaping and condensating on and around the vent is a sound strategy that doesn’t directly affect the coil temperature.

Coil Temperature and VRF Considerations

As stated earlier, the coil needs to be cold for condensation to happen. In the case of traditional single-speed equipment, the coil temperature is partially dictated by fan speeds and runtime, with slower fan speeds and longer runtimes contributing to colder coils. That’s not necessarily the case with VRF systems.

VRF systems actively try to maintain a constant superheat (9°F) and saturation temperature (which you can usually select). In these cases, reduced fan speeds can extend runtime by lowering the delivered capacity, but these will not change the temperature of the coil.

Historically, short runtimes have been attributed to oversized single-speed equipment. The compressor only operates at one speed, so it can’t slow down and vary its operation to satisfy the thermostat setpoint more slowly. Therefore, smaller units with longer runtimes performed way better at dehumidification than oversized units with short runtimes. But again, inverter-driven equipment is different because it can ramp down.

How Inverters Really Work

Inverter-driven equipment, like ductless units and VRF systems, can adjust their heating or cooling output to demand. Many of these residential systems come equipped with technology that converts AC power from the utility source to DC power, then smooths those signals to simulate AC power and turn the motor at speeds other than the standard 60 Hz (or 50 Hz, depending on where you are in the world).

The speed of these electrical signals dictates the compressor’s ability to ramp the motor up or down based on the demand, not just remain at a single speed or a couple of fixed speeds. This design allows inverter-driven equipment to operate outside the BTU ranges on the data plate. In many cases with VRF, the same compressor might be used for multiple rated tonnages because of its ability to operate outside its range. In many cases, the main difference between model numbers may just be the compressor speed programming; the compressor, coil, blower, and even the control board may be the same. But the compressor does have the ability to stretch its range of operation.

When it’s the cooling season and there’s a time of low sensible demand, the compressor can reduce its speed. The ability to operate at a fraction of the maximum capacity without cycling off is called turndown.

Equipment Performance Considerations for Inverter-Driven Systems

The main drivers of equipment performance are saturated suction temperature, return air temperature, and the setpoint. The difference between the return air temperature and the setpoint is known as the setpoint depression. As those two values get closer together, the system doesn’t need to work as hard to meet the setpoint.

As a result, the compressor ramps down, which floats the suction saturation temperature up. This combination warms the coil and decreases the compression ratio. (Remember: compression ratio = absolute discharge pressure / absolute suction pressure.) Low compression ratios are great for efficiency, but the ways inverter-driven systems achieve it also reduce the equipment’s dehumidification capabilities.

Proper charging also plays an important role in maintaining an appropriate compression ratio. If the system is low on charge, it will attempt to maintain its suction saturation setpoint, resulting in low compressor speeds and high suction superheat. Due to the higher temperature, this combination will result in poor latent removal. Compressors will also ramp down if the compression ratio gets too high; that’s a protective measure that warms the coil and kills capacity.

Misconceptions about Inverter-Driven Systems and Dehumidification

The misconceptions about inverter-driven systems usually have to do with the range of operation. While they do indeed ramp up or down to match many loads, they are not infinitely variable.

They also mostly tend to ramp up or down based on sensible BTUs, not latent. That said, in the case of ductless and VRF equipment, the engineering specs will have sensible and latent BTU data that you can use to help you size the equipment to your Manual J load calculations (which, of course, need to be accurate for effective equipment selection). It may not always be easily accessible, but that information does exist and can usually be acquired by contacting the manufacturer.

On top of that, when systems do implement strategies to help dehumidify the space, these strategies are often misunderstood at best.

Equipment-Based Dehumidification Strategies

Latent removal is determined by the equipment’s way of controlling refrigerant flow and coil temperature. Some equipment doesn’t have any control over it, and some equipment relies on multiple data points to change fan speeds, compressor speeds, and even expansion valves to control coil temperature.

As we go over these strategies, keep in mind that the methodology (and challenges of each methodology) will vary by equipment model and manufacturer. The main thing HVAC technicians need to do is understand what they’re working with.

Just the Humidity Display

Many electronic thermostats nowadays display humidity, but that doesn’t necessarily mean that the equipment makes any effort to control humidity.

You and the homeowner might be able to use the humidity display to identify problems, but the equipment may not be able to mitigate those on its own.

“Active” Dehumidification and Overcooling

One method of dehumidification is known as active dehumidification. True active dehumidification happens when a system measures relative humidity (RH) and temperature independently and tries to reach a target RH percentage. The term “active dehumidification” isn’t always used this way, however; it sometimes refers to attempts to remove excess humidity beyond whatever dehumidification we can get with a typical cooling cycle.

A simple form of achieving “active” dehumidification consists of maintaining a cold coil by allowing the system to maintain cooling past the designated setpoint to keep removing moisture. (Some Honeywell thermostats called this condition “droop.”) While the system is running and indeed removing humidity, the downside to this method is that it’s essentially overcooling the space. While humidity isn’t comfortable, neither is being too cold.

Overcooling has a few other pitfalls that aren’t directly related to comfort. The indoor dew point will drop a bit when you overcool the space, but the conditioned space is connected to unconditioned interstitial spaces (including the attic or an unconditioned garage). There is thermal communication between those spaces, particularly via conduction (due to insufficient insulation) and convection (due to gaps and cracks). When you overcool the conditioned space, the temperature of those interstitial spaces will also drop. Attics in particular are notorious for their humidity, so you end up with a jungle if the temperature drops: duct sweating, perfect conditions for microbial growth, etc.

Slowing Fan Speeds

Another way the equipment could achieve active dehumidification without overcooling is to slow the fan speed as the return temperature gets closer to the setpoint. This strategy extends the runtime and drops the suction saturation temperature.

The equipment may run with the lower fan speed and suction saturation temperature until the humidity setpoint has been reached or the unit has overcooled (usually determined by a deadband threshold). The exact details of a reduced fan speed strategy will vary by system and manufacturer, but it is more in line with what the term “active dehumidification” really implies.

Of course, colder coils run a freezing risk and increase the compression ratio, so it isn’t perfect. However, you’ll find that most dehumidification strategies are at odds with energy efficiency.

Modulating Expansion Valves

One way newer ductless and VRF units may control coil temperature is by adjusting the indoor metering device based on relative humidity (RH) sensors built into the equipment. It’s another layer to the compressor’s ability to modulate according to the setpoint depression.

When the sensors detect humidity above the RH setpoint, the indoor expansion valve closes a bit more to starve the evaporator coil. Starving the coil achieves two things:

- Drops the coil temperature to just above freezing

- Extends equipment runtimes (by causing refrigerant to boil off quicker and drop capacity)

Again, there’s the capacity drop; this method is at odds with energy efficiency, but it’s good for dehumidification.

A Quick Note About Dry Mode

Many ductless and VRF systems have a “dry mode,” and there’s a lot of confusion about what this mode really does. In a nutshell, the coil stays in cooling mode with the fan speed on low or LL (low low, as some manufacturers call it). It does NOT actively dehumidify the home or try to reach any humidity targets. It is simply overcooling the space at the lowest possible fan speed available.

In dry mode, the setpoint will disappear from the thermostat. The system will record the room temperature and treat that as the setpoint, aiming to keep it within a ±1.8°F range. Once that threshold is exceeded, the system will cycle off and keep the fan from running for at least six minutes to prevent any moisture on the coil from reevaporating into the air.

Dry mode is an example of passive dehumidification. It’s not trying to reach a humidity target; it’s just running cooling mode with a low fan speed and trying to get more moisture to condensate on that coil without overcooling too much. Daikin explains dry mode in greater detail in its app notes, including a Dry Mode 2.0 setting on most controllers.

A Quick Note About Variable Refrigerant Temperature (VRT)

VRT is a feature of Daikin VRV systems that enables the equipment to assess the outdoor ambient temperature and determine what saturation temperature is needed to meet the demand effectively. This, in turn, causes the compressor to run at varying speeds to meet this moving target of saturation. In cases where we have very high ambient temperatures, the compressor will ramp up as high as it can and maintain a low suction saturation temperature (38°F).

However, on humid, cool nights, the compressor ramps down because the ambient temperature is much lower. Remember: ramping up decreases the suction saturation temperature, and ramping down increases it. Having a warm coil on those cool nights leads to uncomfortable mugginess, even if it feels fine during the day; the temperature of the refrigerant leaving the indoor expansion valve increases with those low sensible loads, which will make the coil do very little for latent heat removal. When that’s the case and VRT is enabled, a 56°F saturation temperature isn’t unrealistic, but it can get as high as 62°F based on deviation from the setpoint. Latent removal would be practically nonexistent with those coil temperatures!

As such, this feature often must be turned off in humid climates. If your particular VRF system or mini-split does not have the ability to set or change saturation temperatures, use caution and always reference the engineering specifications of the equipment you are installing.

Fan On or Off?

There are a few things to consider when deciding whether to run the fan all the time or only when there is a call for cooling. One consideration is sensor location, as this will dictate when there is a call for cooling.

Sensor Location and Why It Matters

VRF temperature sensors may be located in the return airstream and/or remote controllers. Many VRF systems are programmed to determine the space temperature by averaging the readings from the thermistors in the return air sensor and remote controllers.

When the fan is on, the blower moves as needed to reach the setpoint and then ramps down to move very slowly when there isn’t a call for cooling. From a unit location standpoint, things can get a little bit complicated if the return air thermistor is located in an uninsulated return box in a hot attic; if the attic is hot, the constant fan will add to the heat load, something that isn’t typically factored into system design but will affect comfort.

The sensor location may also depend on the use case. It makes more sense to use only sensors that will pick up the space temperature in a building (or portion of it) that will be occupied for much of the day, like an office. That way, we avoid tailoring comfort to an average or another remote sensor that doesn’t accurately represent the comfort of the people within the space. Keeping the fan on might be advantageous in those cases.

Benefits of Keeping the Fan Off

Generally speaking, though, in a humid climate, having the fan stay off except when there is a call for cooling is typically the best strategy for multiple reasons.

Running the fan all the time consumes energy, so that’s one reason not to keep it on. Another reason that’s more specific to humid climates is that running the fan re-evaporates moisture on the coil or in the pan while the system isn’t actively cooling. (That’s the same reason why we choose to have our float switches break R instead of Y at our Central Florida HVAC company.)

The blower is also a pressure driver. Leaks in the ductwork, closed doors, and inadequate return paths all contribute to building pressure imbalances anytime the fan runs. As a result, air gets forced into or out of the structure. In a humid climate, that air brings its moisture with it. While air movement has some benefits, like reducing stratification, you’re better off using a ceiling fan to achieve that than running the blower constantly.

Structure Checklist

So far, we’ve mostly talked about the equipment and understanding how to work with the dehumidification capabilities it has (or may not have). The structure itself also plays a major part in indoor humidity, so we’ll look at the structural items you’ll need to address to help reduce indoor humidity and set up your inverter-driven heat pumps for success.

We’ll dig a little deeper into each of these, but the main items to investigate are as follows:

- Bulk water

- Ceiling, roof, and wall control layers

- Gaps and cracks within the space

- Bath fans

- Duct leakage

- Equipment selection

- Pressure imbalances within the structure

- Kitchen exhaust

- Ceiling fans

- Ancillary dehumidification or reheat

Additionally, these things are all covered in our tech tip about how to do a thorough comfort consultation.

Address Bulk Water FIRST

Bulk water is the biggest problem that will undo pretty much any other efforts to control humidity. Any liquid water that comes in through roof leaks, around windows and doors, or due to plumbing leaks needs to be addressed and removed before we even think about reducing water vapor.

Watch out for things like drain outlets close to the structure or low spots where water pools against the structure outside, too. If water is allowed to pool around and sit against the structure, that water can get in.

To quantify moisture and the effects of bulk water inside the structure, use a moisture meter on the walls to detect where there may be bulk water leaks in the structure. Many plumbing leaks are impossible to see (unless they’ve already spiraled way out of control), so having a tool to help detect those leaks goes a long way.

Address Ceiling, Roof, and Wall Control Layers

Much like flex ducts or onions or ogres, buildings have layers. These layers control air, heat, and moisture; they insulate the structure AND keep water vapor out.

All of these layers are important because both sensible and latent BTUs can be added through a poorly sealed structure. The design aspect becomes a lot more difficult if we have an uncontrollable structure. But what if we have no idea how sealed the structure is?

Blower door testing can give you an idea of how many air changes per hour there are in a home; the higher the value, the less sealed (and less controllable) the structure. Thermal imaging is another tool you can use to see where leakage is happening, as there will be visible color differences in areas where the layers are compromised. That tip leads us to the next item on the checklist…

Seal Gaps and Cracks Within the Space

Gaps and cracks between the conditioned space and interstitial spaces, like attics, are very common. These gaps between the living space and attic are especially common around vents, can lights, and ceiling fans. These need to be sealed and insulated properly.

Again, a thermal imager is a great tool to find plumes where heat is leaking into or out of the structure; you can identify gaps or cracks around windows, doors, recessed can lights, etc.

Ensure Proper Bath Fan Operation

Bath fans should run when people are using the bathroom or shower, and they should NOT run when the bathroom isn’t in use. Exhausting water vapor is a good thing, and we want to do it when the bathroom has a heavy moisture content, such as during and in the 10–15 minutes after a bath or shower. However, when it’s dry in the bathroom, exhausting that dry air puts the house under negative pressure, meaning it will draw air in from spaces we DON’T want, especially moist attics.

Some bath fans come with humidity sensors, and these can be tricky. If they work as intended and only run when the bathroom is in use, then they’re great. If they come on when the bathroom is NOT in use, they cause the pressure imbalance described above and may suck moisture into the structure. Sealing around these vents can help reduce the likelihood of the fan running when the bathroom isn’t being used. However, occupancy sensors that turn on when someone is using the bathroom and turn off within 15 minutes of them leaving may be more reliable.

Address Duct Leakage

Like misused bath fans and kitchen exhaust, duct leakage is also responsible for bringing moist air into the structure.

Return leaks suck air into the ductwork; in the attic, they’re pulling in moist, dusty, dank air that we don’t want to circulate through the home.

Supply duct leaks blow air out, which results in lost capacity and creates a pressure imbalance. The pressure imbalance happens when air from the space leaks out through the ductwork, like exhaust ventilation, so the space goes under negative pressure and pulls in air from wherever it can. Unfortunately, as with return ductwork, that’s often the attic or crawl space.

Proper Equipment Selection

Equipment selection for VRF and other inverter-driven equipment in humid climates is a bit more than just BTUs in, BTUs out; it requires an understanding of the dehumidification capabilities that the equipment really has.

Does the equipment’s thermostat merely display the humidity without controlling it? Or does it let the thermostat drop below the setpoint to continue dehumidifying? Does the compressor turn down with or without adjusting the fan or refrigerant flow?

This information may not be readily available, but latent capacities are often embedded in the engineering specs.

Check Pressure Imbalances Between Rooms

So far, we’ve dipped into pressure imbalances between the conditioned space and external or interstitial spaces, but we can also get pressure imbalances between rooms. These imbalances happen when returns and supplies don’t match, and they’re usually worsened by things like closed doors.

Tools like TEC’s Roomulator can help you discover ways to balance pressure between rooms via jumper ducts, transfer grilles, and door undercuts.

Make Sure Kitchen Exhaust is Appropriate

Kitchen exhaust is another potentially significant driver of leakage. You could be exhausting up to 750 CFM when you’re just trying to boil water, and that air has to come from somewhere—like the attic (surprise!).

Makeup air, which is provided via a controlled fresh-air pathway, is the antidote to the pressure problems produced by a runaway range hood. Of course, that has to be designed properly. We have a tech tip that dives a bit more into makeup air and kitchen exhaust from a code compliance perspective.

Hoods that can passively capture moisture and particulate matter are also worth considering. These tend to have wider designs so that moisture, smoke, and other cooking contaminants naturally flow towards them. Then, you can briefly turn the hood on and vent it out as opposed to running the fan for several minutes, which dumps out (and consequently sucks in) thousands of CFM of air.

Don’t Snub Ceiling Fans

If the customer complains about uneven temperatures that might be due to issues like stratification, the ceiling fan is a useful method that doesn’t introduce the same pressure issues that the HVAC may.

Investigate the specific rooms the customer is complaining about. If they don’t have a ceiling fan (or are perhaps underutilizing it), mention ceiling fan use in the discussion.

Consider Ancillary Dehumidification or Reheat

Dehumidification with a standalone or whole-home dehumidifier uses the same compression-refrigeration method as air conditioners and heat pumps. However, instead of rejecting heat like a condensing unit, a dehumidifier passes air over the condenser coil and reheats it. (That’s why dehumidifiers add sensible BTUs to the heat load in your Manual J load calculations.) Reheat is a critical function of dehumidifiers, and it’s a concept that can be used to your advantage in a humid home, albeit at a cost.

Reheat, as its name suggests, does NOT cool the space; it makes the air warmer and drops the relative humidity. We have a few different reheat methods we can use to add heat to the structure to drop the RH and extend runtimes.

One reheat method consists of using an electric heater to introduce more sensible BTUs and drop the relative humidity. What’s the main drawback?

$$$

Electric reheat is a pit for energy efficiency and money. You only get 3.41 BTUs per watt, which isn’t a lot at all. In fact, that energy conversion rate sets the COP baseline we use for measuring heat pump efficiency (COP of 1). That means your average heat pump with a COP of 3 is three times more energy-efficient than electric heat (which is why, when it comes to heating, electric heat strips are a last resort during the defrost cycle or when the heat pump can’t keep up).

You can also leave curtains and blinds open during the day to allow radiant heat inside. While that’s technically free, your energy bills will increase. There’s no way to get around an energy bill increase to some extent, whether you leave the blinds open, install a dehumidifier, or use electric reheat, either because of extended HVAC runtimes or extra energy costs (or both).

As a side note, if you’re interested in comparing a dedicated dehumidifier to electric reheat, you can read Tim De Stasio’s tech tip comparing the two based on how they performed in his home.

Some Final Thoughts on the Benefits of VRF in Humid Climates

VRF technology comes in many flavors and is one of the more flexible options due to the fact that it can shift loads based on occupancy. (Note: The load shifting capabilities of VRF do best when you have a structure that has a well-controlled envelope: minimal leaks, no bulk water, etc.)

Roman Baugh’s house is a prime example of that; his 2,400-sq-ft home has five indoor units with different capacities to one 5-ton outdoor unit. Although we all know 5 tons is overkill for 2,400 square feet, when you look at the smaller capacity 4-ton outdoor unit engineering specifications and associated derate at elevated outdoor ambients, you will find that this particular model is far more energy efficient, and indoor delivered capacity is different than outdoor capacity when it comes to VRF.

He also has a 3.5-ton vertical air handler and a few 7,000-BTU slim ducted units in the bedrooms. The slim ducted units go into an unoccupied mode during the day (around 78–80°F), and the 3.5-ton unit cools the central areas of the home: kitchen, dining room, living room, and bathroom. At night, that vertical air handler goes into unoccupied mode, and the ducted units cool the bedrooms, which can also be adjusted based on the preferences of each occupant.

While the 5-ton outdoor unit can cool most of the structure if there ever is a reason to run the 3.5-ton air handler and slim ducted units to cool simultaneously, there is almost no need. The smaller-capacity indoor units allow occupants to customize which units run and when. This flexibility also comes in handy during the shoulder seasons.

At the end of the day, inverter-driven systems are pretty great, but we need to understand how they work and support them in humid climates. That starts with controlling the structure (and REALLY starts by eliminating bulk water), and then you have to understand what the equipment can and can’t do. The equipment isn’t a wave of a magic wand; we need to set it up for success, and that [often] means sacrificing efficiency for dehumidification.

Comments

Great article. Wish I had this info 7 years ago. After building a small ICF home here in Central FL with Ductless mini’s we found out during the first year our concrete walls added allot of moisture and setting our Mitsubishi units to dry only froze us out quick with a .83 ACH blower door. We then installed a 60 pint per day Aprylair on a scheduled 5 hour run while no one was home. After the walls finally dried out the first year or so we found we could run it 3 hours after morning showers and keep humidity down around 45 – 50. Depending on how dry the shoulder months are we have Alexa turn in on when needed. We can cool the whole home with a Honda 3000 inverter during storm season and one 6000 BTU unit and some well place fans

Great article. Wish I had this info 7 years ago. After building a small ICF home here in Central FL with Ductless mini’s we found out during the first year our concrete walls added allot of moisture and setting our Mitsubishi units to dry only froze us out quick with a .83 ACH blower door. We then installed a 60 pint per day Aprylair on a scheduled 5 hour run while no one was home. After the walls finally dried out the first year or so we found we could run it 3 hours after morning showers and keep humidity down around 45 – 50. Depending on how dry the shoulder months are we have Alexa turn in on when needed. We can cool the whole home with a Honda 3000 inverter during storm season and one 6000 BTU unit and some well place fans

The Cyberpunk 2077 inspiration sounds really interesting for a speed game about a robotic ball dodging obstacles. I’m curious if the score mechanics elaborated further on the page at https://hypackelgames.com/games/slope-cyber.

The Cyberpunk 2077 inspiration sounds really interesting for a speed game about a robotic ball dodging obstacles. I’m curious if the score mechanics elaborated further on the page at https://hypackelgames.com/games/slope-cyber.

This sounds like a really fun game, especially the ability to build a winter park. Do you know if the customization features mentioned on https://hypackelgames.com/games/snow-rider-3d are extensive?

This sounds like a really fun game, especially the ability to build a winter park. Do you know if the customization features mentioned on https://hypackelgames.com/games/snow-rider-3d are extensive?

This sounds like a fun sequel with even more challenges than the original. I’ll have to check out the details on the game page at https://hypackelgames.com/games/obby-prison-escape-2.

This sounds like a fun sequel with even more challenges than the original. I’ll have to check out the details on the game page at https://hypackelgames.com/games/obby-prison-escape-2.

That description of the blend of skill and humor sounds like fun; is the customization system pretty detailed? I think I also read more about the features over at https://hypackelgames.com/games/douchebag-workout-2.

That description of the blend of skill and humor sounds like fun; is the customization system pretty detailed? I think I also read more about the features over at https://hypackelgames.com/games/douchebag-workout-2.

To leave a comment, you need to log in.

Log In