BACK

Fresh Air in Commercial Buildings: Economizer Sensors and Settings

Fresh Air in Commercial Buildings: Economizer Sensors and Settings

500 BTUs per Person Per Hour?

500 BTUs per Person Per Hour?

Commercial Contactor Considerations

Commercial Contactor Considerations

Stacking Evaporator Coil Stages

Stacking Evaporator Coil Stages

#commercial

Tech Tips:

This tech tip is based on a presentation by Joey Henderson, a veteran symposium speaker and excellent HVAC educator. You can learn more about Joey and the work he does at joejoehvac.com and his YouTube channel HERE. Simply put, indoor air is often nasty. People cough up and exhale germs, and cracks in the envelope […]

Read more

I heard a great presentation by Ron Auvil on VAV systems, and it got me thinking… Can you size a commercial system/perform a block load by the number of occupants? Yes! No, I'm just kidding. That's crazy talk. There is way more to it than that. However, in a commercial environment, while the building's perimeter […]

Read more

This tip was created by Jason Pinzak and originally posted on the HVAC Technician's Facebook group. It is reposted here with permission from Jason. Thanks! Contactors are useful in commercial and industrial applications, particularly for controlling large lighting loads and motors. One of their hallmarks is reliability. However, like any other device, they are not […]

Read more

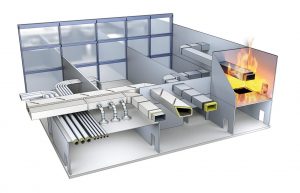

In commercial HVAC, you will find several different types of multi-stage evaporator coils: intertwined (shown above), horizontal face split (one coil on top of another), and vertical (side by side). When staging a horizontal evaporator, pay attention to ensure that stage #1 is on the bottom and stage #2 is on the top. If stage […]

Read more