BACK

What is a Thermocouple?

What is a Thermocouple?

Averaging Thermistors and How They Work

Averaging Thermistors and How They Work

Heat Pump Defrost Sensor vs. Thermostat

Heat Pump Defrost Sensor vs. Thermostat

NTC, PTC and Thermocouples – Short #183

NTC, PTC and Thermocouples – Short #183

#thermistor

Tech Tips:

In HVAC, we work with thermocouples for temperature measurement all the time, but we may not understand the difference between a thermocouple and other types of temperature measurement sensors. A thermocouple is just two different types of metal connected at a “junction” that generates a small voltage with a temperature change. Older furnaces would often […]

Read more

There was a question in the Facebook group a few days ago about averaging sensors. There are two common configurations/methods used for averaging. The first is simply a setting in a thermostat or control where it reads separate sensors, and then the thermostat itself averages out the readings using its software. For example, if the […]

Read more

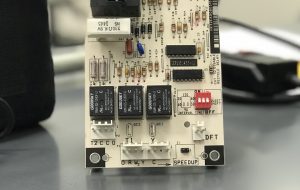

When you work on a heat pump system and want to test defrost, you can follow many different test procedures to test the board and sensors. Most involve “forcing” a defrost by shorting out pins on the board or advancing the time of the defrost initiation and installing a factory-provided pin jumper. Lots of pins […]

Read morePodcasts:

In this short podcast episode, Bryan dives into NTC, PTC, and thermocouples. NTC and PTC are two types of thermistors, and all three tools are used to sense temperature. Thermistors are resistors that change their resistance based on a change in temperature. They must be powered, and the resistance changes the amperage. You can […]

Read more