BACK

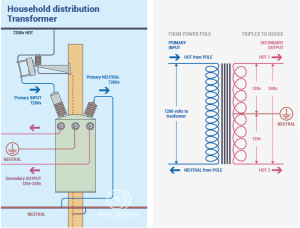

Understanding 240-Volt Circuits

Understanding 240-Volt Circuits

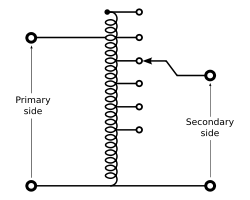

What Makes an Autotransformer Different?

What Makes an Autotransformer Different?

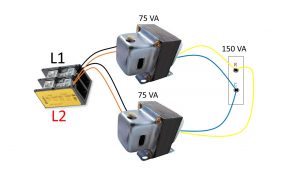

Connecting Transformers in Parallel

Connecting Transformers in Parallel

Multi Tap Primary Transformers

Multi Tap Primary Transformers

Careful With That 40VA Transformer

Careful With That 40VA Transformer

#transformer

Tech Tips:

It can be useful to think of a multimeter as a “voltage drop” tool. Bryan covers the concept here in an excellent class that I highly recommend. This concept was a big help to me as I began to truly learn how to use a multimeter. A meter reads the voltage differential between two points. […]

Read more

The definition of a transformer is a device that changes the voltages in an alternating current circuit. You may have heard of an autotransformer or a buck-boost transformer, and these terms are usually used for the same type of device; they just highlight different aspects. A transformer does not need to be a buck-boost to […]

Read more

I had an old-timer tell me that you can never connect two transformers together because they will “fight one another.” If you are anything like me (and heaven help you if you are), a cartoon in your head starts playing whenever someone says something like that. In this case, I imagine two transformers with boxing […]

Read more

Have you ever seen a low-voltage transformer like the one shown above? It has multiple input (primary) taps for a good reason. It is common to find three-phase and single-phase equipment rated to operate on both 240v and 208v power. That is because three-phase power can either be 208v leg to leg when the building […]

Read more

A 40VA transformer is rated for 40 VA or volt-amps on the secondary. For a typical 24 volt secondary, this is simply using Watt's law to calculate amperage. (For more information on Watt's or Ohm's laws, please check out this article HERE.) 40 ÷ 24 = 1.666666 ∞ (round up to 1.67 already) So, you […]

Read more