Get Tech Tips

Subscribe to free tech tips.

Scroll Compressors in a Changing Regulatory Landscape

This tech tip is based on an HVAC School podcast episode about scroll compressors and new refrigerants with Jeff Kukert and Tom Fesenmyer from Copeland. Jeff is the senior technical trainer, and Tom is the manager of technical services. You can listen to the original podcast HERE, and you can explore Copeland’s vast selection of compressors and resources for low-GWP refrigeration HERE. The Copeland Mobile app is also a great resource, and you can download it in the Google Play Store for Android or the App Store for iOS.

Even techs who live under a rock know that the regulatory landscape around refrigerants has changed a lot in the last five years. Technicians, manufacturers, and distributors alike have had to adapt quickly to lower GWP targets, and the national 700 GWP cap that led the industry to use A2Ls like R-32 and R-454B in air conditioning is just the beginning. Commercial and industrial refrigeration systems are being subjected to even lower GWP limits.

We’ve seen some obvious changes to equipment, tanks, and tools—including red service caps, left-handed threads, and brushless DC motors in recovery machines and vacuum pumps. Compressors are no exception. Different refrigerants have different operating pressures and temperatures, so compressors—which raise the temperature and pressure of the refrigerant—need to be designed to handle the temperatures and pressures of A2Ls and even natural refrigerants like CO2 and R-290 in the commercial refrigeration world, and scroll compressors are no exception.

Review of Basic Refrigerant Terms

When we talk about anything related to the refrigerant transition, two things always come up: ASHRAE’s refrigerant classification system and GWP.

ASHRAE classifies refrigerants based on their toxicity (Class A for non-toxic or B for toxic) and flammability (Class 1, 2L, 2, and 3 in order from least to most flammable). We combine these and end up with classifications A1, A2L, B2L, etc.

R-22 and R-410A are A1 refrigerants. However, R-22 depleted the ozone layer, so it was phased out in 2020. Instead of focusing on the ozone layer, new regulations focus on global warming potential (GWP). GWP is the measure of how much heat a vapor traps in the atmosphere. Carbon dioxide (CO2) sets the standard and has a GWP of 1. By comparison, R-410A has a GWP of 2088.

The refrigerant transition has focused on moving to lower-GWP refrigerants in HVAC (and shifting to lower-GWP products in other industries, like aerosols and foams). As we’ve had to begin moving away from the familiar A1s, we’ve seen A2Ls begin taking their place. In residential and light commercial applications, these have primarily been HFC R-32 and blend R-454B.

A Common Misconception About A2Ls

Despite what many technical trainers and organizations have said over the past few years, many people think A2Ls have propane (R-290) in them. That is FALSE. R-290 is an A3 refrigerant (and a very good one at that), not A2L, and the A2L blends do not contain any A3 refrigerants.

R-32 is a pure refrigerant, like R-12 or R-22. It does not contain any other refrigerants. R-454B is a blend made of two other A2Ls: 68.9% R-32 and 31.1% R-1234yf (an HFO refrigerant used in automotive air conditioning since the 2010s). R-290 is nowhere to be seen in that formula.

Quick Recap of the Refrigerant Transition

The AIM Act was signed in 2020 and authorized the EPA to set the timeline for reducing the production of high-GWP HFCs like R-410A. In 2021, the EPA created a timeline to reduce the production of high-GWP HFCs by 85% over 15 years—not a total ban on production.

However, while the importation and manufacturing of the refrigerants themselves won’t be banned, there are different rules for the manufacturing, importation, and installation of equipment that uses those high-GWP A2Ls. The EPA published GWP restrictions, ranging from 700 to a mere 150. The EPA also published deadlines for manufacturers to discontinue making equipment and for contractors to stop installing field-assembled equipment. Parts may continue to be manufactured and installed indefinitely.

The manufacturing of residential and light commercial split systems with GWPs greater than 700 was discontinued on January 1st, 2025. Those systems can be installed through 2025, but installation will be illegal after January 1st, 2026. Chillers, non-chiller industrial process refrigeration, and some other specialized applications have later dates and may have different GWP limits as well.

For example, supermarket rack refrigeration systems with less than 200 pounds of charge have a 300 GWP limit, and those with more than 200 pounds have a 150 GWP limit. Both system types have an installation deadline of January 1st, 2027.

Information about different applications and their manufacturing and installation deadlines is available on the EPA’s website HERE.

Changes to Service Practices

We’ve covered the changes that come with adopting A2L systems in several tech tips, including Don Gillis’s tech tip about the changes to tanks, systems, and service procedures.

In reality, the transition from R-410A to A2Ls isn’t a huge shift in terms of readings and field practices. Compared to the transition from R-22 to R-410A, the operating pressures of R-32 and R-454B are much closer to those of R-410A. Service practices will change minimally if you’ve already been doing best practices, like performing a nitrogen pressure test or pulling a deep vacuum; they’ll just be required now.

Nothing new if we’ve been following best practices all along.

How Parts and Equipment Manufacturers Adapt to A2Ls

These changes are a lot to ask of contractors, and manufacturers have had to act quickly to design and manufacture new parts and equipment for the replacement refrigerants. While R-32 and R-454B aren’t that much different from R-410A in terms of operating pressures, there are some key differences manufacturers need to design for, especially when it comes to compressors.

As Copeland has adapted to the times, they’ve stuck with their scroll compressor design because of its efficiency and reliability.

Why Scroll Compressors?

Scroll compressors consist of a fixed scroll, which doesn’t move, and an orbiting scroll. The orbiting scroll moves in a somewhat circular, oscillating motion. As that orbiting scroll moves, it squeezes pockets of vapor together and moves that vapor to the center of the scroll in the process, where that vapor is then discharged.

That’s such an efficient design because there can be lower-pressure vapor in the outer scroll cells while high-pressure vapor is in the center scrolls at the same time. They’re also versatile, as we see them in residential and commercial applications, including low-temp refrigeration. Apart from their efficiency and versatility, they tend to be quieter and are built with fewer moving parts than rotary and reciprocating compressors.

Credit: Copeland

The challenge is that we can’t use R-410A compressors with these new A2Ls and expect the same reliability and efficiency. Governing bodies like the U.S. Department of Energy set specific SEER and EER targets that new HVAC equipment must meet. That means each time there’s a new refrigerant, manufacturers adjust the scroll geometry for the best possible efficiency.

Refrigerant pressure, temperature, and oil requirements also factor into the design. R-32 has higher discharge temperatures than R-410A, and compressors need to be able to handle those higher temperatures. R-32 also requires a more viscous oil type to dissipate that heat. R-454B has a little bit of glide, which is another design and service consideration.

Oil Types

Copeland Bulletin 93-11 has a list of refrigerants used in Copeland scroll compressors and the oil types they require. It also has notes on phaseouts, brand names, alternatives (where applicable), and special use cases.

R-410A uses POE oil in most cases. R-32 and R-454B do as well. However, R-32 uses a different type of POE oil due to its higher discharge temperatures. Excessive discharge temperatures can cause oil to break down, which then causes internal components to overheat. When we have those high discharge temperatures, we need a thicker oil that doesn’t break down and can keep the parts lubricated.

R-410A and R-32 use POE-36, but R-32 uses POE-46. As such, R-32 compressors need to be designed to work efficiently with a different oil type.

Glide

Glide is a feature of refrigerant blends that have different saturation temperatures. Instead of relying on a single saturation temperature for a given pressure (and vice versa), we need to rely on dew point, bubble point, or midpoint, which is all explained in THIS video.

Refrigerant blends with different boiling points have some special considerations when it comes to capacity and reliability (such as preventing liquid refrigerant from flooding or slugging the compressor). Those of you who worked on R-22 systems that were replaced (or especially topped off) with R-407C probably remember the efficiency hits those units took with the new refrigerant. Even if you recovered the R-22 and replaced the mineral oil with POE, the capacity still wasn’t the same.

You may not have realized it, but R-410A has glide. The temperature glide is very small—around 1°F between the dew and bubble points. R-454B has a little more glide than R-410A: about 1–2.5°F. That’s practically nothing compared to R-407C’s glide, which was sometimes as high as 11.5°F, but it still requires a different compressor design than R-410A.

Copeland Compressor Nomenclature and Refrigerant Compatibility

The Copeland Mobile app tells you which refrigerants are compatible with the compressors in its database. You can either look up the model number directly or enter some basic information about the system (including capacity in tonnage or BTU/h, voltage, refrigerant type, etc.).

Traditionally, Copeland’s scroll compressors for air conditioning have had model numbers starting with Z. Scroll compressors for A2Ls and other flammable refrigerants will have model numbers starting with the letter Y. We can differentiate R-32 from R-454B by the letter after Y: YA for R-454B and YP for R-32.

Replacement Compressors for R-410A Systems

Even though there are no new R-410A residential and light commercial units being manufactured, we’ll still have compressors available for years to come. The EPA’s restriction is on manufacturing new complete systems, not individual parts. There are no rules stopping the manufacturing of R-410A compressors.

Copeland will continue to make R-410A service models in its new LXE line, which will replace compressor models beginning with ZP (ZP**K5, ZP**KA, etc.). There are 80 LXE compressors that can replace 277 legacy compressors, so one LXE model may be a suitable replacement for multiple legacy models. These compressors will be listed as ZPLXE for single-stage compressors and ZPSLXE for two-stage.

Information about Copeland’s LXE product line, including brochures and FAQs, is available on their website. Copeland also recorded a free webinar about their LXE line.

Commercial Refrigeration Scroll Compressors

Several of Copeland’s refrigeration scroll compressors are compatible with several refrigerants, including R-454A, R-455A, R-454C, R-404A, and more. The Copeland Mobile app shows the compatible refrigerants for each compressor type. In the screenshot below, you can see the model number, oil type, and list of compatible refrigerants.

As with the air conditioning compressors, the model numbers starting with Y are compatible with flammable refrigerants. Some of Copeland’s models are even manufactured for R-290 (propane, which is an A3 refrigerant), which is becoming more popular with the even tighter GWP restrictions in commercial and industrial refrigeration.

Additional GWP Restrictions

Currently, several heavy commercial and industrial refrigeration applications have lower GWP limits than the 700 we’ve seen for residential air conditioners and heat pumps. We’re already seeing GWP limits of 150 and 300 in market refrigeration and industrial applications. Some A2Ls fit the bill already (namely R-454A and R-454C), but there is still the question of what future regulations might entail.

The European Union and the United Kingdom have already reached the point where R-32 is slated to be phased out as part of the F-Gas Regulation (which aims to phase out HFCs by 2050). We’re not there—at least not yet—in the USA, but if we want to stay ahead of the curve, we should pay attention to the replacements.

The refrigerants that have been discussed as replacements are “natural” refrigerants R-290 and carbon dioxide (CO2 or R-744).

Natural Refrigerants and Specialized Compressors

R-290 is extremely efficient and has a low GWP (3). However, it’s highly flammable and requires small charge sizes as a result. On the other hand, CO2 is an A1 refrigerant with a GWP of 1, but its operating pressures are very high.

Despite those challenges, plenty of facilities successfully use these refrigerants. Several organizations offer training on these systems, and compressors that can handle the unique challenges of R-290 and CO2 already exist. Just as Copeland optimized their scroll compressors for R-32 and R-454B, they’ve designed scroll compressors for R-290 and subcritical CO2 (as well as semi-hermetic compressors for subcritical and transcritical CO2).

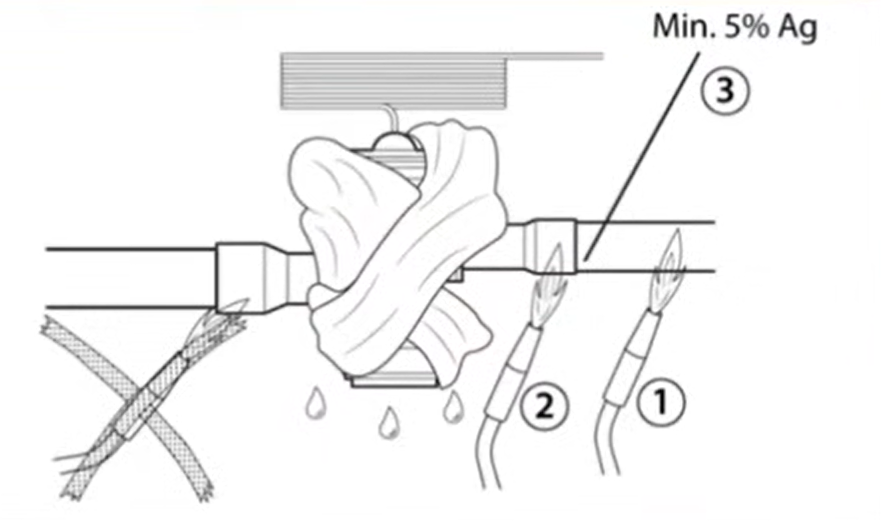

R-290 Scroll Compressors

R-290 scrolls sold in the United States come in vertical and horizontal varieties. Vertical scrolls for R-290 can be used in medium-temp, extended medium-temp, and low-temp refrigeration. Horizontal scrolls are made for medium-temp and low-temp applications. The table below shows horizontal scrolls for A2Ls and R-290:

Credit: Copeland

CO2 Scroll Compressors

CO2 refrigeration is a unique beast, so I’ll leave you with THIS tech tip if you want to learn more about it, but the main thing you need to know is that you may deal with subcritical or supercritical operation (or both). Subcritical CO2 only changes between liquid and vapor in its circuit, and it’s common in low-temp refrigeration. Supercritical CO2 exceeds a temperature and pressure called the critical point, at which the temperature and pressure decouple, and is more common in medium-temp CO2 systems. Copeland’s ZO scroll series is for low-temp subcritical CO2 systems, and their ZO(D) series specifically refers to their digital scrolls.

Again, the CO2 only changes between liquid and vapor. In a booster system with medium-temp and low-temp refrigeration, the subcritical CO2 will be compressed and discharged into the medium-temp circuit with CO2 from the medium-temp evaporators and bypass valve (shown below).

Credit: Copeland

In a hybrid cascade system with HFCs, the discharge CO2 goes to a heat exchanger that gives off some of that heat to the medium-temp HFC circuit.

Credit: Copeland

Copeland has several great resources about CO2 refrigeration. You can find white papers, product listings, and more at the “CO2 Solutions” part of Copeland’s website HERE.

As our industry continues to adapt to the HFC phasedown and lower GWP targets, education and awareness will be vital. Free resources like the Copeland Mobile app are invaluable—you can find exact matches for replacement compressors from local distributors, get clarity about which refrigerants a compressor is designed to handle, and access AE bulletins and training at your fingertips.

The EPA website also contains timelines and deadlines for GWP targets as well as important legal documentation like final rules. While this change has been more than frustrating for several contractors, there are plenty of resources to help us stay informed during this technological transition.

Comments

To leave a comment, you need to log in.

Log In