Get Tech Tips

Subscribe to free tech tips.

What Makes a Thorough Comfort Consultation

This tech tip is based on an HVAC School podcast episode with Tim De Stasio. Tim has written several articles about HVAC design on his blog, several of which he has been generous enough to share with HVAC School. Tim’s focus is on humid climates, and moisture mitigation is one of his main focuses in HVAC and building design. You can support him on his YouTube channel HERE.

The process in this tech tip isn’t exhaustive; you will need to adjust it to your climate, local building codes, and other market-specific considerations. Due to the sheer length of this procedure, we’ve also included a quick outline at the end, and you may also use Ctrl + F to look up specific key terms.

Let’s be honest: when a lot of us hear “comfort consultation,” we imagine some guy in a white shirt walking up to a house with a clipboard in hand, ready to sell a 5-ton, 26-SEER inverter system with a UV light and close the deal in 30 minutes tops. That’s NOT what a comfort consultation should be.

A thorough comfort consultation requires a contractor to look at the building as a system, not just sell a new appliance. Contractors deploy tools, including specialty tools like blower doors and precision manometers, to slow down, zoom out, and collect data to get the full picture before prescribing a solution. After all, a physician writing a prescription without diagnosing a patient is considered medical malpractice; why shouldn’t it be the same for home comfort and safety?

In our market (Central Florida) and Tim De Stasio’s (Coastal North Carolina), moisture is also a huge issue. The solution to those problems often requires a mix of HVAC equipment and building envelope modifications. We’ll go over some of those unique aspects of our own comfort consultations as well.

One thing Tim cautions, however, is to avoid gathering too much data. A good rule of thumb is not to bother gathering data unless you plan to use it. There’s no shortage of tests and readings you can take. Tim focuses on the testing he’ll need to develop a report and scope of work. Beyond that, it’s academic and may not be practical or pragmatic.

How Does a Comfort Consultation Even Come Up?

Barring a handful of customers who know somebody in the building science side of HVAC, very few people will seek out a comfort consultation on their own. Here’s how customers usually find out about a comfort consultation:

- Customer calls an HVAC technician out because they’re having comfort or moisture problems

- HVAC technician hooks up gauges and takes some airflow measurements at the unit, and everything looks fine

- With no answers to be found with the unit alone, the HVAC technician suggests a more holistic approach via a comfort consultation

At Kalos, we’ve been revamping our maintenance programs to include a thorough whole-home check on the first maintenance. We generate simple reports of any issues we find and then offer a more in-depth comfort consultation to customers who have comfort issues that go beyond just the HVAC unit.

How to Price a Comfort Consultation

A comfort consultation could either be a paid front-end service or a loss leader.

Due to the considerable time and specialty equipment required, Tim and our team at Kalos offer it as a paid service and recommend that other contractors do the same. An upfront price tag keeps the scope honest and sets expectations. And remember—comfort consultations don’t happen whenever there’s a no-cooling emergency; they require a lot of preparation and on-site work.

Once a customer is interested, both parties need to do a little bit of homework before the actual consult can take place.

Pre-Visit

Before even setting foot in a customer’s home, contractors need to ask some questions and set some expectations for the comfort consultation. The customer will need to do a little bit of work here, so the more time before the consultation, the better.

Gathering Information from the Customer

A basic idea of the customer’s current comfort complaints can provide context for trends that become apparent during the consultation. We can gather this information by sending a simple survey a few weeks ahead of time. Some of the questions on this form should be:

- What rooms feel the most uncomfortable? At what time of day?

- Do you close the bedroom doors at night?

- Any odors?

- How high are power bills compared to neighbors?

- Is there anyone in the home who’s on allergy/asthma medication?

The goal isn’t to pry into the customer’s personal life; it’s to get a glimpse into their indoor health and power consumption, especially if they’re not aware that their problems might be related to their HVAC system or building envelope. For example, a customer might have a backstock of Benadryl and chalk up their illness to general allergies without realizing their indoor air is the problem.

You can use something simple like a Google Form to collect and record this information, but there are plenty of options out there.

Never collect data that you don’t intend to use. Your final report to the customer should reference the original survey. For example, if their main concern was condensation and high humidity, your final report should clearly say: “Your home is having moisture and condensation because…”

Preparing the Customer

Once the customer’s basic information and complaints are on record, they need to understand what will happen during a comfort consultation, what contractors will need to access, and that care arrangements will need to be made for pets and kids.

The client will need to know that the comfort consult is an all-day project. A contractor may not be able to guarantee they’ll be out of the house by 4 PM so that guests can come over for dinner. Customers must know to plan accordingly.

Scheduling also requires more forethought than one might realize. Comfort consultations get the best results on days when the temperature is decisively hot or cold. An average cool or warm temperature will make issues found on thermal cameras less apparent than if there were a bigger temperature contrast. As a general rule, comfort consultations are best on days with at least a 5°F indoor-outdoor difference to make those thermal images pop.

The customer also needs to know that the comfort consultation itself is a long and invasive process, so their pets and children can’t be in the house. Even cats that sleep most of the day could still sneak out when a blower door is being set up, so it’s just a risk not worth taking. Customers may need to board their pets for a day and send the kids to a friend or family member’s house.

Tim prepares his customers by sending them THIS video.

Consultant Prep

A comfort consultation is a big job that requires specialized tools. If you start offering this service, you’ll need to set aside extra time to make sure you have everything on your truck and organized.

Safety needs to come first, and comfort consultations require contractors to get into sketchy attics and crawl spaces. Bring Tyvek coveralls and a respirator—it sounds like overkill, but when you’re in a crawl space with the nasty M-word all over it, you’re going to be grateful you had it on hand.

As far as tools go, your lineup will likely include:

- Smartphone and/or tablet with diagnostic and load calculation app(s)

- Refrigerant probes

- Thermal camera

- Duct leak tester (depending on the scope)

- Plastic and painter’s tape (to seal off vents)

- Blower door

- TrueFlow grid

- Flow hood

- Flow box

- Smoke pencil

- Precision manometer

- Power quality meter

- Handheld IAQ monitor

- TEC’s Roomulator

Software is equally important. When you do a comfort consultation, ask the customer for permission to use their guest Wi-Fi so that all your smart tools can link up and photos can upload quickly without syncing issues. Here’s what you’ll need on the technical side:

- Tool-compatible diagnostic apps (e.g., measureQuick and TEC’s TrueFlow app)

- Load calculation software (e.g., Conduit or Amply)

Software can also help keep data organized. Reports to the customer will need to be able to contain embedded photos with annotations, so that’s a key consideration when figuring out how to organize and present information. Here are some decent options that won’t break the bank:

- SafetyCulture (iAuditor)

- CompanyCam

- Google Forms or JotForm

You could even go for an ultra-customized solution with Google AppSheets, which lets you create full-fledged apps with no coding needed. It just takes time and dedication.

Tim De Stasio uses SafetyCulture for his comfort consultations. You can create a free account with SafetyCulture. Then, you can reach out to him on LinkedIn if you’d like him to share his workflow with you so that you can develop yours accordingly.

Introductory Conversation

For many of us, it’s in our nature to grab our tools right away and start touching everything. We’re going to want to avoid doing that when we first arrive. (Call it the hands-in-pockets approach.)

Instead, a comfort consultation begins with a thorough conversation with the customer. We’re giving them a chance to take the lead and tell their story—what they’ve noticed and what they want to solve. If they could walk us around the home and point out the muggy rooms, sweating or dirty vents, mildewy baseboards, or any other points of interest, that would be ideal.

Then, we can carry out our inspection and begin taking pictures and notes.

Exterior Inspection

The building orientation, shell, and penetrations all matter, so a comfort consultation requires us to inspect and document all of those. Sun and wind are directional, so comfort consultants need to consider radiant heat and wind-driven pressure, both of which can significantly impact heat and moisture loads.

But first, we should record the outdoor ambient temperature and dew point to put the findings into context. Then, we pull out our cameras.

Start by taking pictures of each side of the building, noting the orientation. The sun rises in the east and sets in the west, so we want to know which sides of the building will deal with those heavier heat loads in the morning and evening. These pictures also document windows and awnings, which will also affect the heat load. Large trees near the building can also block out the sun, so we need to be aware of how all site conditions affect the heat load.

Wind drives pressure, which can drive infiltration through penetrations for electrical meters, disconnects, or cable boxes. Those pathways allow heat and moisture to get into the building envelope, especially during storms. Bulk water can also get in during storms, and it’s far worse than water vapor for moisture problems.

Bulk Water Considerations

Bulk water contains far more moisture than mere water vapor, so we must consider drainage when we do comfort consultations, especially in humid climates.

For HVAC professionals, the first thing that comes to mind is probably the condensate drain. During this inspection, we want to see how far away it is from the home and if there are any signs of pooling or runoffs (including visible water, damp dirt, or erosion).

In addition to the condensate drain, gutters and downspouts also need a look. We should assess their condition and see if certain downspouts show more wear than others, which could indicate an uneven grade and that bulk water could be pooling in a low area. When that’s the case, one downspout on the low side might take the majority of the bulk water and get overwhelmed during heavy rains.

If the water pools beside the structure, especially if there’s a basement, chase pipe, crawl space, or even a slab below grade, that’s a serious issue. We want to look at where the downspouts discharge the water in relation to the house and note any signs of pooling near the structure, where it could seep into the envelope.

Venting Considerations

We also want to look for vent pipe terminations—kitchen, bath, and dryer vents. If we document each one, we’ll know how many to look for indoors and make sure those numbers match. In some cases, we’ll find that construction contractors have vented into attics instead of outdoors.

Credit: Tim De Stasio

Interior Inspection

As with the exterior, we’ll take pictures of all the rooms and inspect them thoroughly, including pantries, closets, and laundry rooms. Record the indoor temperature and dew point as well to give context to some of the thermal camera and visual inspection findings.

The rooms should be organized in the comfort consultation checklist, and there should be a way to label or annotate photos. That way, we can associate problems with specific rooms.

Looking for Moisture

When we conduct a visual inspection in a humid climate, we’re really looking for signs of moisture. Blackish spotting around vents, condensation on vents, peeled paint or wallpaper, and warped surfaces like baseboards are all red flags we must document.

We can even take a moisture meter and measure the baseboard, shoe molding, and the lower drywall. When the building has a slab foundation, these surfaces wick moisture due to capillary action (think of how water gets from a tree’s roots to its entire network of branches). These readings will allow us to see how moisture is moving into the building envelope through the ground.

Keep in mind that dirty areas around supply vents may also indicate other issues that AREN’T necessarily related to moisture but are still worth investigating further. One of those potential issues is when the inner lining of flex ducts breaks down and deposits onto the vent. In our experience at Kalos, we’ve also found that black streaks on vents sometimes happen when occupants burn a lot of candles.

Thermal Imaging

When we look at walls and ceilings with a thermal camera, we can see temperature differences between areas with sufficient insulation and those without it. Areas without adequate insulation will show up warmer or colder than other areas (depending on the weather; these spots will be brighter on warm days and darker on cool days).

Credit: Tim De Stasio

Thermal cameras can also help us identify thermal bridging. Metal studs and other framing materials take up space where insulation could’ve been, but they can also exacerbate heat transfer by conducting heat into or out of the building. As with areas with insufficient insulation, these areas will have a stronger color contrast on the thermal camera and often resemble straight lines.

Missing insulation and thermal bridging are both common problems. Even if there’s nothing we can do about those, the customer should know about these issues so that they’ll be able to work with an appropriate contractor.

Venting

We’re going to confirm that all of the venting terminations we saw outside have a match. Again, we may find that bath fans have been vented to the attic, which is a code violation that can cause severe moisture and microbial issues in the attic.

Now is also the time to check the venting itself on all appliances, including vented fireplaces. If there’s a vented fireplace, find the dampers and note their state and condition (as those will matter when it’s time to do a blower door test). If there’s gas venting, look for any signs of backdrafting (such as corrosion or melting on top of the water heater).

Most of all, check for low-level carbon monoxide (CO) detectors. Even in all-electric homes, a family could be at risk of CO poisoning if they start the car in the garage (especially if there are push-button remote car starters that could be bumped in pockets). That’s a safety device that should always be in place—and an upgrade that should always be discussed with the customer if it isn’t currently there.

Attics and Crawl Spaces

The real dirty work begins when we get into the attic or crawl space, especially the latter. We should always come prepared with a respirator and Tyvek coveralls to protect ourselves from respiratory hazards that could already exist in there.

Since attics are on top of the house and crawl spaces are underneath them, we have to consider a few different things between the two.

Attics

The obvious places to check in attics are recessed lighting fixtures and the penetrations for HVAC ductwork, plumbing vents, bath fans, and electrical junction boxes and wires. These are some common sites for air leakage between the attic and the building envelope.

Attics have soffit and ridge vents, and we want to make sure those aren’t obstructed. There should be soffit baffles in place—if not, that’s definitely something to document. Same if there are soffit vents but no ridge or gable vents to allow for actual ventilation to take place. Ridge vents can also be tricky, as the slot may be too small, or there may be a beam blocking the only path for air movement between the deck boards. When the vents are blocked, the dew points can get extremely high due to restricted air movement.

Attics that span the area over the garage and the home also have some unique considerations. We want portions of the attic over the garage to be sealed off from the attic above the home. Failing to seal these two areas off can lead to combustion gases from the garage seeping into the attic and then into the home. Some attics may have kneewalls that support the rafters and separate the unconditioned attic from a loft, bonus room, or finished room over the garage (FROG). These should be backed with a rigid air barrier, have adequate insulation, and be sealed to prevent attic heat and moisture from getting in.

Additionally, top plates often have small leaks that can let a lot of air pass through. Top plates are where the ceiling and walls meet, and a small gap (even as small as 1/16”) between the ceiling drywall and the top plate adds up when we calculate the total length of the walls.

Crawl Spaces

The crawl space will have foundational walls, which we will need to take pictures of. Look for growth, especially near downspouts or on the windward side of the building (i.e., where the wind comes from), and see if there’s an area where water has been pooling.

Efflorescence can also give us some clues about the impact of moisture on the building materials. That’s a whitish powder that shows up when the building materials get wet and dry out. As the water evaporates, it brings minerals from deep inside the building materials to the surface, which look like salt on the surface.

Check at least one penetration. If the penetration is sealed with spray foam, it usually means the others are as well. If there is no spray foam, then it would stand to reason that the others need to be sealed as well. It’s also a good time to check for plumbing leaks, which can also lead to moisture problems and are worth bringing to the homeowner’s attention.

Encapsulated Attics and Crawl Spaces

In humid climates, vented attics and crawl spaces are just not good ideas, but they’re still around. Moisture control is completely unchecked, so it’s best to seal the unconditioned space and either condition or dehumidify it.

In an encapsulated attic, we can check the integrity of the encapsulation by completely closing the attic, turning off all lights, and looking for daylight. Bright spots indicate gaps that need to be addressed.

If the crawl space IS encapsulated, check the vapor barrier. The vapor barrier should fully protect the crawl space, but some local codes may not have required complete coverage at the time of installation. The vapor barrier should cover the foundation walls and piers completely, but even when this has been done, it’s often rare to find it done right.

Ductwork in Attics and Crawl Spaces

If the ductwork is in the crawl space, check the general condition—look for kinks and damaged or disconnected ducts. Look at connections to see how the duct is sealed; we’ll want to make sure nothing’s disconnected and that there’s enough sealant (mastic). Take the time to look for dampers and see if the ducts are wet. Issues with any of those things can cause comfort issues (and potentially health problems).

Ventilation Tests

The “V” in HVAC is perhaps the most commonly overlooked part of the acronym, but it’s vital to a comfort consult. This part is where we’ll start breaking out specialty tools like the flow box. Both TEC (exhaust fan flow meter) and Retrotec (FlowBox) make these. A smoke pen will also come in handy to see how air moves when exhaust fans are activated.

We often come across bath fans that have a labeled capacity of 50 CFM but deliver only about 20 CFM due to the ducting (kinks, compressed flex, and caps). Those airflow-measuring boxes measure pressure and CFM, so we can compare our CFM readings to the bath fans’ labeled capacity.

Flow boxes are often impractical for larger kitchen exhaust hoods. When we can’t get a CFM measurement, we can do a visual inspection with a smoke pen. The smoke should exit the area through the range hood. It’s also a good idea to ask customers how they use the hood and whether there’s any way to bring in fresh makeup air. Those kitchen exhaust hoods suck out a lot of air, so when we have big ones, we may need powered makeup air to provide sufficient fresh air. We have a tech tip about international and Florida-specific codes related to exhaust ventilation and makeup air, which you can read HERE.

We don’t have to get too crazy with dryer vents. We just want to ensure that the dryer transition is as short as possible, passes through a smooth wall, and is actually connected securely to the appliance. A visual inspection will suffice.

Gathering Structural Data for Load Calculations and Blower Door Tests

Thanks to companies like Conduit and other ACCA-approved software, load calculations are now easier than ever. The software uses LiDAR scanning technology to create 3D models of rooms. Simply walk around with the tablet and scan the area, and a model that shows walls, corners, ceilings, and counters will develop in real-time.

Credit: Tim De Stasio

After the home is scanned, there is an option to tweak the 3D floor plan model and specify rooms. Then, we can fill out the other required Manual J criteria, including building materials (plus interior and exterior finishes), weather station (for pulling climate data), number of occupants, insulation, appliance loads, ventilation loads, and ancillary loads. Users can also specify zones within the home. Tim shows this process in THIS video.

Conduit also shares the floor area and volume of the models it creates. The volume is also necessary for a blower door test (as we want to calculate ACH50 or CFM50, which are the air changes per hour and CFM leakage, respectively, under 50 Pascals (Pa) of negative pressure).

Pre-Blower Door Test: Measuring Building Pressures

Before we bring out the blower door, we want to get some basic information about air movement and pressures in the home BEFORE bringing the house under negative pressure. Most of these results will need to be put into context with a blower door later, but they can give us an overview of what we can expect from the blower door test.

Stack Effect

The first thing we’ll want to do is measure for stack effect, which is the movement of air based on different temperatures (and densities) of air. In other words, it’s one way we can get leakage that isn’t driven mechanically or by wind.

To measure the stack effect, leave all interior doors open with ALL mechanical appliances OFF. Then, we’ll use a precision manometer (like TEC’s DG-8 or Retrotec’s Solo) to measure the indoor pressure with respect to the outdoors. The blower door test will put these readings into context later.

Worst-Case Depressurization Test

With a baseline measurement for the basic stack effect, the next step is to see if backdrafting is a possibility when all exhaust pathways are active. This is a safety test that could potentially save the occupants’ lives. Houses with large families could have multiple exhaust fans running at the same time, so we want to make sure combustion appliances can vent out even in the most extreme possible exhaust scenario.

Like the stack pressure test, we’ll first measure the house with interior doors open with reference to the outdoors. However, instead of leaving all mechanicals off, we’ll turn ALL of the exhaust pathways ON—bath fans, kitchen exhaust, clothes dryer, etc., and see if the house goes under negative pressure and by how much.

Credit: Tim De Stasio

If possible, use a smoke pencil near a chimney to visualize how combustion gases may behave under these conditions. If the house is under negative pressure and the smoke doesn’t vent out, then that means those combustion gases could continue to build inside the home whenever the fireplace, furnace, or gas water heater runs.

Dominant Duct Leakage Test

As with the stack effect and worst-case depressurization tests, we’ll want to measure pressure once again with reference to the outdoors (and with the interior doors open). This time, we’ll want just the central HVAC system to run.

We won’t get detailed duct leakage data from this test, but we might be able to tell whether there is heavy supply OR heavy return duct leakage. Remember: return leakage sucks air into the ductwork (positive pressure on the envelope), and supply leakage blows air out of the ductwork (negative pressure on the envelope).

Keep in mind that low numbers, like the reading in the picture below, may not necessarily indicate that we’re in the clear. It’s possible that the house has an extremely leaky envelope, and it’s also possible that there’s bad supply and return duct leakage canceling each other out.

Credit: Tim De Stasio

Building Pressure Balance Test

Finally, we get to close the doors! When we conduct a building pressure balance test, we want to run the central HVAC system with the doors closed. First, we’ll measure the main body of the home with reference to the outdoors.

Then, we’ll measure the pressure between each room and the hallway. We’ll want to measure pressure differences across those closed bedroom doors.

In a house with central returns and supplies in each room (as is common in Florida and North Carolina), we’ll see positive pressurization in the rooms and negative in the main body of the home. Positive pressure isn’t bad since we’re pushing air out instead of sucking air in from the attic, but that’s only in the rooms. The main body of the home is still under negative pressure and will attempt to pull air in from wherever it can to balance things out.

If we want to size jumper ducts or transfer grilles to help even out those pressures, we can use TEC’s Roomulator. The Roomulator is a small card with a ruler on one side and sizing instructions on the other. We must use a precision manometer with a probe underneath the door, press the Roomulator against the door and frame, and crack open the door until the manometer reads 3 Pa. Once the manometer reads 3 Pa, we can use the ruler side of the Roomulator to measure the gap and use that number to see how many CFM we need to move from that room and size jumper ducts, transfer grilles, or door undercut modifications accordingly. You can learn more about the Roomulator, see it in action, and order a pack for yourself on the TEC website.

Credit: Tim De Stasio

Pre-Blower Door Test: Safety Checks

The blower door test is a heavily disruptive process because it depressurizes the building envelope. We need to make sure we’re not stirring up harmful materials or bringing them inside the home during the test.

First, we should pay attention to combustion appliances, specifically how those appliances vent and whether we need to close any fire dampers. Again, those will mostly be furnaces, gas water heaters, and fireplaces. Leaving dampers open could draw soot into the building envelope. (Now is also a decent time to perform a quick combustion analysis to see how the fuel burns.)

We also want to be mindful of substances inside the home, namely, suspect microbial growth, asbestos, or vermiculite (used for insulation and fireproofing). All three of these items may cause or worsen respiratory illnesses, and depressurizing a house will stir them up. We could potentially pressurize the house instead, but a thermal imaging camera will be less likely to capture clear issues than if the home were depressurized.

Blower Door Test

Start by setting up the blower door in the main entryway of the home, making sure all windows and other exterior doors are closed. Manual J also requires us to tape off supply registers and return grilles; if we skip this step, duct leakage will also factor into the blower door test results. We want to measure true infiltration.

With the blower door in place, set the fan motor up to depressurize the house to -50 Pa. When the pressure holds steady at -50 Pa, we’re interested in two main values: CFM50 and ACH50.

ACH50

ACH50 represents the air changes per hour at -50 Pa; the entire volume of the home is filled with 1’x1’x1’ boxes of air, and one ACH represents the replacement of ALL those boxes of air with new ones. Therefore, lower ACH50 values indicate fewer air changes per hour, which should mean the building is tight, but that’s not always the case.

One air change means that the entire volume of air in a home is replaced; that’s the square footage multiplied by the height. Homes with tall ceilings, like the McMansions that drive us crazy, may just have fewer air changes per hour because the added volume from the ceiling height disguises leakage.

CFM50

Meanwhile, CFM50 is better for giving us an idea of how manageable the leakage is. It tells us how many 1’x1’x1’ boxes must come in to fill the building envelope’s volume; some of those boxes will be lost to leakage, so that number will exceed the home’s volume.

Credit: Tim De Stasio

If the CFM50 is close to the home’s volume, we’ll know that the house is workable in its current state. When we start to see CFM50 readings doubling and tripling the home’s volume, we’ll know we’re dealing with loose homes with leakage that borders on uncontrollable (or perhaps even is).

Break Out the Pressure Pan

With the house under negative pressure, we have the perfect opportunity to look for pressure drops at penetrations—supply and return vents, bath vents, can lights, etc.

We want to find the most problematic areas of leakage (i.e., the greatest pressure drops). Higher pressure drops indicate stronger connections to the attic. The sealing is poorest and requires the most attention in those areas, and it’s definitely worth keeping in mind that recessed lights are infamously leaky.

Zonal Pressure Diagnostics (ZPD)

Whenever we have encapsulated attics and crawl spaces, ZPD helps us measure how connected they are to the living space (and then how connected they are to the outdoors). We’re not necessarily measuring leakage between those zones; we’re measuring the relative size of the hole between a zone and a house and how it compares to the size of the hole between that zone and the outdoors. Higher Pa readings indicate smaller holes.

ZPD also comes in handy when we’re measuring how connected a garage is to the living space. Again, we can get combustion gases when a car idles indoors, and we don’t want those (especially carbon monoxide) to be able to enter the home.

Genry Garcia wrote an entire series of tech tips on ZPD for those of you who want the nitty-gritty details (Part 1, Part 2, and Part 3).

Thermal Imaging Under Negative Pressure

With the main pressure diagnostics out of the way, the next step is to ramp down the blower door to -20 Pa and look at the home once again with a thermal imaging camera.

This time, look specifically at the usual culprits:

- HVAC boots

- Can lights

- Bath fans

- Electrical penetrations

- Attic access hatches

- Exterior doors

- Windows

- Top plates

Leakage will show up in the form of plumes that are either brighter or darker than the surrounding area. Be sure to take these photos and annotate them by specifying the locations where these issues are and circling key points in the photos so that the customer can see the problematic areas.

Measure Duct Leakage to Outside?

At this point, we should have already collected data about possible duct leakage from visual inspections, thermal images, and pressure pan readings. If those were obtained earlier and we’re NOT anticipating a major duct sealing or replacement procedure (which would require us to test in and out), there likely won’t be a need to do a complete duct leakage to outdoors test.

In Florida, we mostly have accessible attics and can visually assess the situation to see if a detailed sealing or replacement job might be necessary. If there’s no reason to suggest that those solutions would be needed, we simply move on without a detailed test.

If you want to learn more about measuring duct leakage to the outdoors, THIS video by Chris Hughes and Adam Mufich may help.

HVAC Performance

We’re more than 5000 words in, and NOW we’re finally at the HVAC equipment.

This inspection is going to start with the air handler and condenser. Take pictures of nameplates and make sure to note the model number and serial number. These values tell us the nameplate capacity, which will partially help determine how well the equipment matches the Manual J load calculation. Later, we will see how much of that capacity is actually being delivered.

Visual Inspection

Look for general cleanliness and condition concerns, taking photographs along the way. When the air handler cabinet is open, look for suspect growth on the panel insulation (or damage to the panel insulation), and see if there’s standing water. How’s the blower wheel? Is it dirty? If so, that might mean the filter is a poor fit or too inefficient at capturing particles.

Does the filter fit well? Is it a fiberglass boulder catcher or a pleated filter? Media filters are great IAQ options, so we can see if there is a media filter slot. If not, is there room for a media filter slot? Media filters are upgrades that we ALWAYS recommend at Kalos, and we make the customer decline the option if they don’t want one.

Check out the drain and safeties. Is there a primary AND secondary float switch? Are those installed properly? Is the drain pitch okay? Is the drain line insulated? Are there any sags where there could be double-trapping going on? These are all potential design and performance issues that a comfort consultation may be able to resolve.

On the electrical side, how does the wiring look? Are the connections tight, or are they loose or showing burn marks or signs of pitting? How does the capacitor look? (We should measure the capacitor under load later, but check for signs of a weak capacitor, like bloating, or perform a bench test if you can.)

At the outdoor unit, check its overall cleanliness and location on the site. How do the coils look? Is there soil all over the fins? Does the coil show signs of corrosion or damage? What about the line set insulation and line splices? Are those intact and adequately protected? (In Florida, we use a UV-resistant coating on line set insulation.)

Break Out the Tools (and measureQuick)

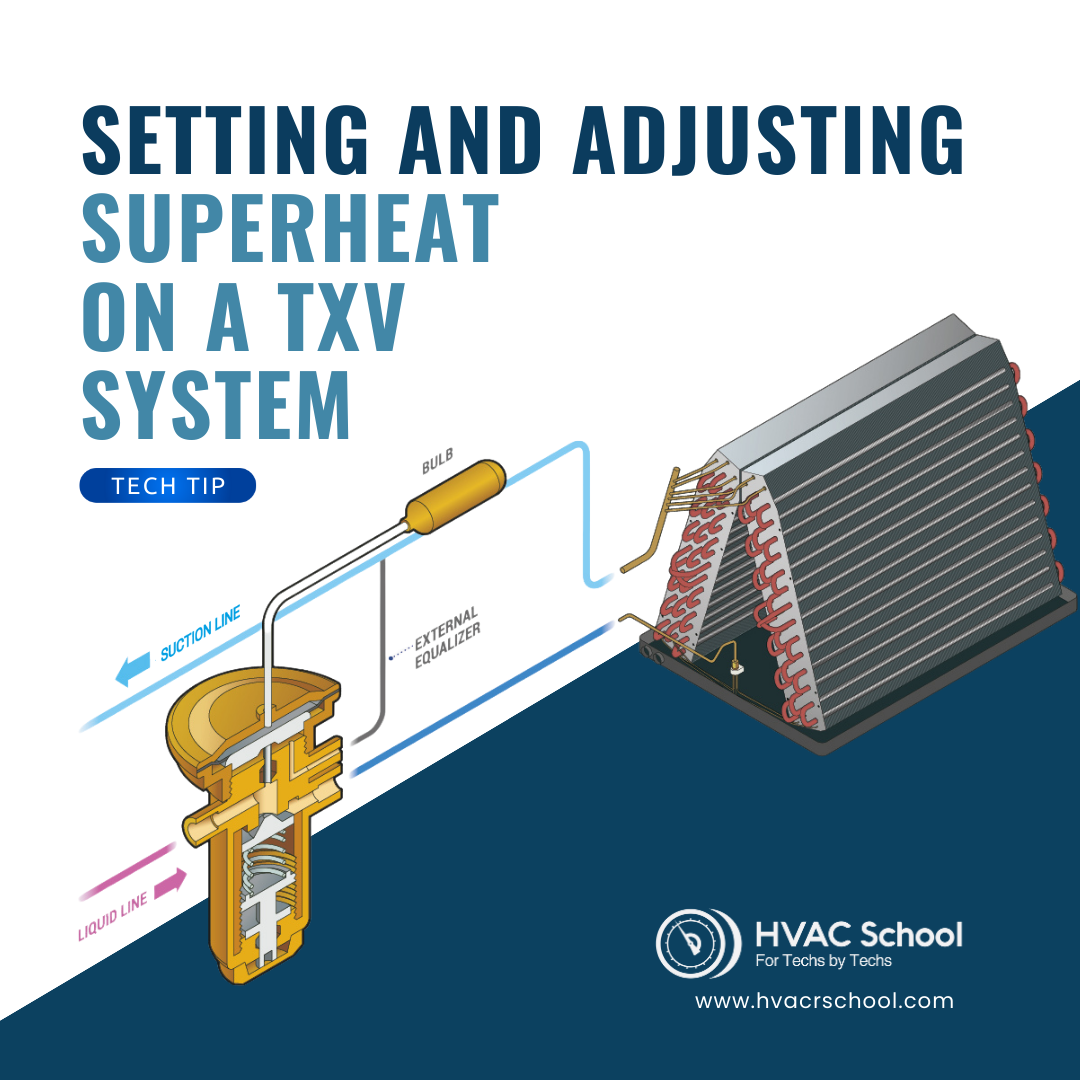

The goal of a comfort consultation is to get as complete a picture as possible, so that means we’ll deploy our probes to measure the refrigerant charge, static pressure, and delta T.

We also get to break out some fancy tools like a wattmeter and the TrueFlow grid (by TEC). The TrueFlow grid slides into the filter slot and measures the CFM; the TrueFlow app requires users to enter the tonnage of the equipment, so the app configures the CFM per ton and will show whether it’s in the acceptable range once it has a reading to go off of.

With information about airflow and how much heat we’re moving (including humidity, which our psychrometric probes can pick up), we can find our delivered capacity. If you use measureQuick, the app does that for you, and it breaks the total capacity down into sensible and latent capacity (which we’ll compare to the Manual J load calculation later):

A wattmeter can tell us how much power is being consumed when the HVAC system runs. Measuring power quality will also let us know how many of the volt-amps are actually doing work when the air conditioner runs. (However, if we have a system with an ECM, we might see a low power factor. That may be concerning, but it’s actually normal. THIS tech tip explains why that happens.)

With the information about power consumption, we can take our delivered capacity a step further and come up with the SEER and EER ratings and coefficient of performance (COP). Again, measureQuick does the math automatically.

Compare to Manual J

With the nameplate capacity, total delivered capacity, and Manual J load calculation data, it’s time to compare those numbers.

Comparing the nameplate capacity to the delivered capacity tells us how well the equipment is running compared to how well it should run under ideal conditions. Several things can reduce the capacity of the equipment, including poor airflow from bad ductwork or restrictions.

Manual J gives us the loads that need to be handled by the equipment—both sensible and latent. We can compare these BTU loads to the nameplate capacity to see if the equipment itself is oversized and if the delivered capacity might be hiding potential oversizing effects.

For example, we may have a 3-ton unit (36,000 BTU/h) but have a load calculation that tells us we only need 23,500 total BTUs per hour, which would be handled by a 2-ton unit. But maybe our delivered capacity is only around 29,000 BTUs. A 3-ton system is grossly oversized! However, the delivered capacity is relatively poor, just under 2.5 tons, so common oversizing issues like long runtimes and mugginess are way less bad than they could be—at the expense of LOTS of wasted energy. These are very common problems in humid climates like Florida and North Carolina.

We need that data to have informed conversations with customers about their potential solutions. Comfort consultations are about real solutions with numbers that back up our work; when the customer sees the reports and the fact that our observations are backed by data, they’ll know we’re not selling snake oil.

Indoor Air Quality (IAQ)

IAQ is often associated with bolt-on products that may or may not help the customer. That’s very unfortunate because indoor air quality is one area where we can really make a positive difference for people, especially those who have family members with allergies or compromised immune systems.

The formula is pretty much the exact same as it is for quantifying building leakage and HVAC performance, though. We need to collect data.

The quick and easy way to collect data is to take a snapshot with a handheld IAQ monitor in a central location. A handheld monitor can’t tell us any trends, but it can give a baseline and identify pollutants. It’s just a snapshot of one moment in time.

On the other hand, with the customer’s permission, we can install a HAVEN central air monitor in the return and let it collect data for at least two weeks. Instead of providing just a snapshot of the home’s IAQ, it provides trends and tracks the following important values:

- Relative humidity

- Dew point

- Temperature

- PM2.5 concentrations

- TVOC concentrations

The HAVEN central air monitor also senses airflow, almost like a built-in hot-wire anemometer. Whereas the handheld monitor gave us just a snapshot, the HAVEN gives us an entire movie that tells a story. We can see when humidity spikes and when certain contaminants spike (such as during cooking or cleaning). Since this installation may be temporary, it may not look very pretty, but the important thing is that the HAVEN monitor is mounted in a place where it can collect meaningful data.

Credit: Tim De Stasio

Of course, cooking and cleaning will always release contaminants; there’s nothing we can do about that except educate the owner about storing cleaners responsibly. However, we can look at when humidity spikes. Is humidity particularly bad at night when the air conditioner isn’t running?

Reporting Process

After assessing the structure, envelope, equipment, and air quality, we share our findings and photos with the customer in a rough field report.

The field report is more of a tool for the contractor than the customer; it may just be a rough and dirty copy of your checklist. This step is mostly just a data dump and won’t come with any immediate action items, and we should make it clear that the customer will see a lot of notes but very few conclusions. At the very least, this rough copy shows the customer the work we’ve done and that they’ve paid for. Tim sends a rough copy of the SafetyCulture checklist once the invoice has been paid.

Credit: Tim De Stasio

We need time to assess all the data and spot patterns to come up with an all-inclusive solution. If a HAVEN IAQ monitor was installed, we also need to wait for it to collect enough data for us to notice trends. It takes at least two weeks for the findings to marinate and to develop the final report.

Final reports are meant to be clean, organized, and as easy to follow as possible for customers who aren’t familiar with our vocabulary. The challenge here is that they can still be quite extensive. Here are some tips to streamline the reports:

- Explain things visually where possible and keep written work concise

- Include photos that best represent the main issues, not every single one

- Create simple graphs or charts in programs like Google Sheets

Credit: Tim De Stasio

When creating graphs, it may be helpful to represent comparisons—like the Manual J load calculation, delivered capacity, and nameplate capacity—in a bar graph to show how closely the items line up with each other. In the pictures below, you can see how Tim has used one bar graph to compare the load, nameplate capacity, and actual delivered capacity, and he used another to compare the customer’s home insulation with the latest code requirements.

Credit: Tim De Stasio

Next Steps

After presenting the findings, prepare a list of recommended actions in order, starting with the items with the biggest ROI and impact, and include cost estimates (if possible). Be sure to reference all of the concerns found in the comfort survey.

Air sealing is a common solution, but not a lot of HVAC contractors do it. If you don’t, it’s okay to refer contractors you trust and leave prices blank for services you don’t provide. (Quick note about air sealing: ALWAYS want to encourage the customer to air-seal their home BEFORE adding insulation.)

The list of recommendations will likely be long, and to the homeowner, it could look daunting. It’s helpful to assure them that it’s more like a roadmap so that they can take the steps they need to take to solve their comfort problems. A customer may not be able to do everything all at once, and that’s okay. That’s why we need to prioritize the items with the highest ROI when we present that list.

It’s also helpful to set expectations. There is an element of discovery that comes with envelope improvements. Sometimes, air sealing and insulation require creating access points to areas of the building that were not accessible during the comfort consultation. Make sure you explain to the customer that the scope of work may change a little once these areas are uncovered.

As HVAC contractors, we are not expected to be the ones making all the improvements needed. Developing relationships with like-minded contractors in your market to refer this work out to them is a great strategy. You’ll likely get more HVAC referrals back from them.

After the customer has expressed ANY interest in the action items on that list, it’s on us to test out and show the customer the difference. That test-out step should also be included in the plan.

Common Action Items in Humid Climates

In Florida specifically, these are the most common problems we come across:

Air Sealing

Leakage is a huge problem. We’ll want to seal top plates, can lights, bath fan housings, chases, and penetrations. THEN, we can insulate if needed.

Adding insulation before sealing is a bad idea. Air leaks can bypass the insulation, and microbes that naturally come with moisture can proliferate on blown-in insulation.

Pressure Balancing

We often see high bedroom pressures with reference to the main body of the house. When that’s the case, we add jumper ducts or returns to keep bedroom pressures under about 3 Pa with the doors closed. (Again, TEC’s Roomulator does all the math for you.) In turn, this strategy should keep the main body near neutral with reference to the outdoors.

Fix or Replace Ductwork

Flex ducts get a bad rap, and they just happen to be very common here. They’re great, but they get their bad rap because they’re often not installed correctly.

Issues with dealing can be resolved with a duct sealant (i.e., mastic). We may also have to remove parts of the ductwork, especially if it’s kinked, crushed under something, or compressed.

The insulation should be R-8 or better if the duct is in an unconditioned attic.

Add Controlled Ventilation and Dehumidification

If a house has a massive range hood and no powered makeup air to compensate for the exhaust, that’s DEFINITELY an item that should go on the list.

Ventilating dehumidifiers can also help dry the air out AND bring in fresh air. There are several ways to duct ventilating dehumidifiers, but the best way in our climate is to have a dedicated return and an outdoor air path into the dehumidifier, a supply duct that ties into the HVAC supply ductwork, and a smart control.

Install Correctly Sized Equipment

Sizing new equipment like-for-like is pretty standard, but we can make better choices with our load calculation in hand. We want to size the equipment capacity and sensible heat ratio to match the load measured, not the sticker on the old condenser.

Remember: higher sensible heat ratios have excellent sensible heat removal but may struggle with high latent loads.

Keep Bulk Water Out

Bulk water is the enemy. It contains way more moisture than water vapor, and we want it to stay OUT of our homes.

To do that, we can recommend adjusting downspouts, fixing grading so that water doesn’t pool right beside the building, and addressing wind-driven rain paths through electrical and low penetrations by sealing them.

Decouple the Attic Spaces

The garage contains chemicals and vehicles that can introduce some nasty substances into the air. We do NOT want VOCs and CO to seep into our home, so we can separate the garage attic from the house attic. That way, air from the garage is less likely to make it into the house attic and seep into the living space.

In addition, we want to seal the attic off from the conditioned space. Adding or replacing weather strips on attic hatches stops leakage through gaps in the opening. Can lights are also extremely problematic, so we can consider upgrading them to ones with sealed trims or ICAT-rated ones (insulation contact air tight).

Safety Upgrades

Address any concerns that came up during combustion analysis and add low-level CO alarms if the customer doesn’t already have them.

Testing Out

After improvements have been made, we should always arrange to come back and perform the same tests we performed during the consultation:

- Blower door test

- Room-to-room pressure tests

- Duct leakage test (if applicable)

- Test for delivered capacity (with measureQuick)

Now is also the time to show IAQ data if we’ve had a central air monitor in place. Look for new trends in the data after changes have been made.

The goal of testing out is to ensure that any modifications we or other contractors made are truly making a difference. The results won’t be perfect, but comfort consultations are not supposed to chase perfection. They’re meant to make a home safe, controllable, and comfortable most of the time, and the customer needs to see the before-and-after differences to understand how their home is now safer, more comfortable, and more controllable than it was.

General Outline

As you can see, a comfort consultation is an all-day job, and we really do leave no stone unturned in a thorough one. Here is a quick recap of all the steps in order:

Pre-check

- Customer questionnaire

- Briefing the customer on the comfort consultation process

- Preparing tools, software, and PPE

On Arrival

- Have a conversation led by the customer

Visual Inspection (Exterior)

- Record outdoor temperature and dew point

- Photograph all sides and note orientation

- Check grading, gutters, and downspouts

- Find and photograph all vent terminations and the condensate outlet

- Note any signs of bulk water pooling

- Look for wind-driven rain paths into penetrations like disconnects

Visual Inspection (Interior)

- Note indoor temperature and dew point

- Photograph every room and name them in your notes

- Thermal scan ceilings, exterior walls, and around windows

- Moisture-test shoe molding and lower drywall

- Inspect vents and match interior fans to exterior terminations

- Check for a low-level CO alarm

Attic Inspection

- Verify soffit baffles

- Make sure insulation and beams aren’t blocking intakes

- See if knee walls are backed with a rigid air barrier and sealed

- Look for top plate cracks

- Inspect bath fan and light penetrations

- Verify garage/house attic separation

- If the attic is encapsulated, turn off the lights and look for daylight

Crawl Space Inspection

- Photograph the foundation walls

- Look for efflorescence

- Check vapor barrier coverage up walls and around piers

- Look for plumbing leaks

- Note any growth and how it lines up with windward walls and downspouts

Ductwork Inspection

- Photograph ducts, sealant, and insulation thickness

- Look for obvious kinks or other problem areas

Ventilation Checks

- Test every bath fan with a flow box

- Smoke-test the kitchen hood and ask the customer whether it uses makeup air

- Check the dryer transition

3D Scan and Load Calculation

- Scan the home with an app that uses LiDAR technology

- Make modifications to the 3D model, if necessary

- Input appliance, weather, occupancy, glass, and other relevant Manual J data

Measuring Building Pressures

- Stack effect check

- Worst-case depressurization

- Dominant duct leakage

- Building pressure balance test (bedrooms vs. the main body)

Combustion Safety Checks

- Photograph appliances, noting venting and terminations

- Do a quick combustion analysis on water heaters or furnaces

- Close dampers as appropriate

Blower Door Test

- STOP if you see asbestos, vermiculite, or heavy mold

- Close windows and exterior doors, taping off supply and return registers

- Depressurize to -50 Pa

- Record CFM50 and ACH50

- Pressure-pan bath fans, can lights, and a few key supplies/returns

- Do zone pressure tests on encapsulated attics and crawlspaces

- Back the blower door to -20 Pa and re-run the thermal imaging camera

Duct Leakage

- Determine whether a duct leakage test is necessary

- If so, conduct a duct leakage test with the blower door in place

HVAC Equipment Testing

- Visually inspect the equipment, filters, wiring, etc.

- Photograph nameplates and model/serial numbers

- Measure airflow, delivered sensible and latent capacity, and running efficiency

- Compare the Manual J load, nameplate capacity, and delivered capacity

IAQ

- With permission, install a HAVEN central air monitor and leave it for two weeks

- Gather a quick reading with a handheld IAQ monitor

Reporting

- Give the customer a rough field report immediately after the comfort consultation

- Spend two weeks finalizing the report and reviewing HAVEN data

- Send the concise final report two weeks after the comfort consultation

- List recommended actions in order of highest impact and ROI

Testing Out

- Conduct the same tests performed during the comfort consultation

- Make sure the customer sees the before and after readings

Final Note for Humid Climates

If we want to keep homes safe, water is—and always will be—public enemy number one. It’s a problem in the vapor state: water vapor from attics seeps into the living space. In the liquid state, bulk water can seep in and damage building materials, which can lock water in. That may seem like it’s outside the typical HVAC contractor’s wheelhouse, but it’s our responsibility to care for the customer’s comfort and safety in their home. Finding these water-related issues and making the customer aware is simply part of the job.

We may not be the contractor who can fix everything that’s wrong with the site and building envelope, but that doesn’t mean we can’t identify problem areas and give the customer the power to make an informed decision for their health and safety in their home. A thorough comfort consultation is about putting that knowledge and power in the customer’s hands.

Comments

To leave a comment, you need to log in.

Log In