Get Tech Tips

Subscribe to free tech tips.

Dielectric Grease: What It Is and How To Use It

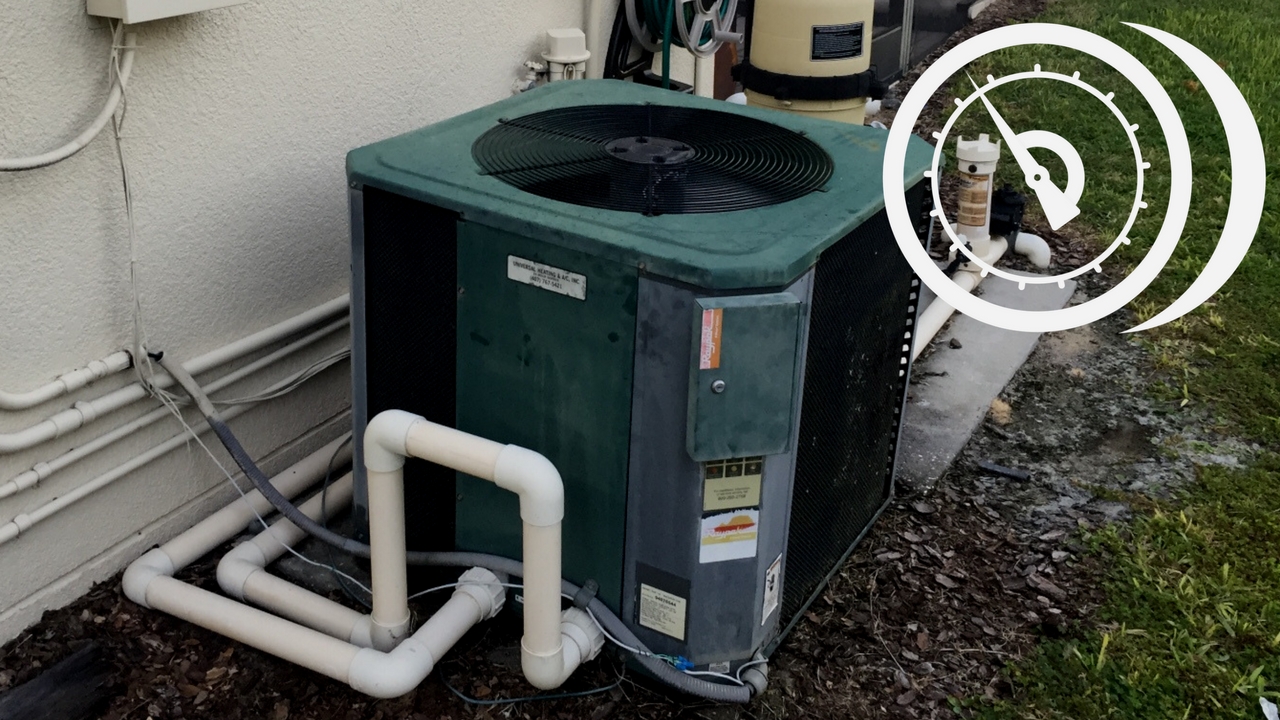

Dielectric grease is an often misused and misunderstood product that could easily benefit HVAC/R technicians in various ways. From food service to electrical connections, dielectric grease can help lubricate mechanical components and prevent corrosion on electrical connections. But we need to understand what it is in the first place before we can properly apply it in the field.

Dielectric grease is silicone-based grease with insulating properties. Common uses for dielectric grease include electrical connections, spark plug wires, and mechanical connections. The most common misuse of dielectric grease relates to electrical connections.

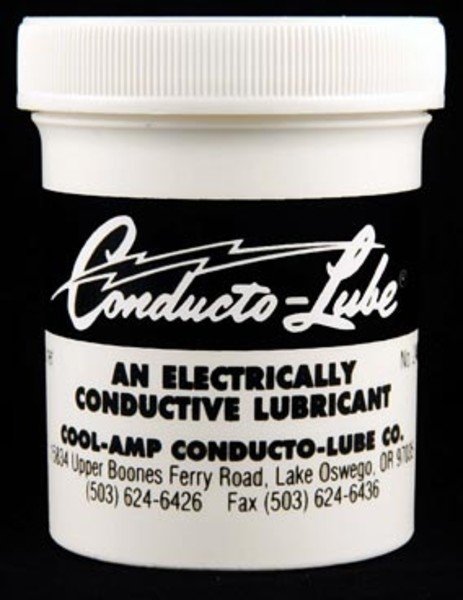

I mentioned that dielectric grease acts as an insulator, yet many technicians mistake silicone grease as conductive. If you're looking for conductive grease, Conducto-Lube Silver or any carbon conductive grease will do. Conductive grease is for conducting electricity from one conductor through the grease to another conductor.

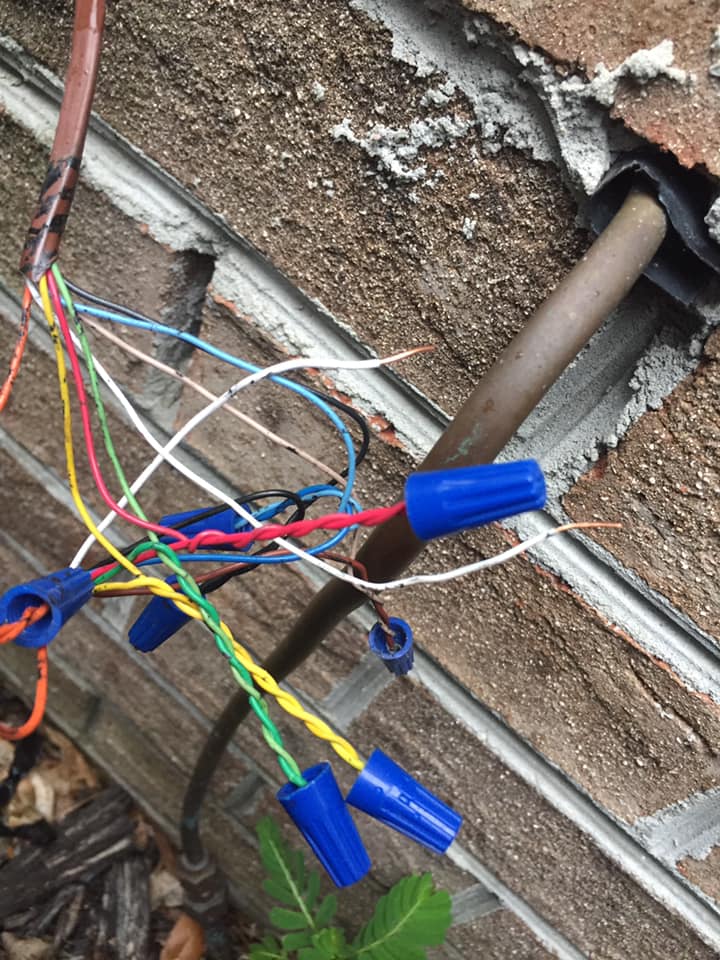

To apply silicone dielectric grease properly to electrical connections, make sure the conductor mating surfaces are bonded before applying the grease. In coastal climates, low voltage wiring is particularly in danger of corrosion, especially right on the waterfront.

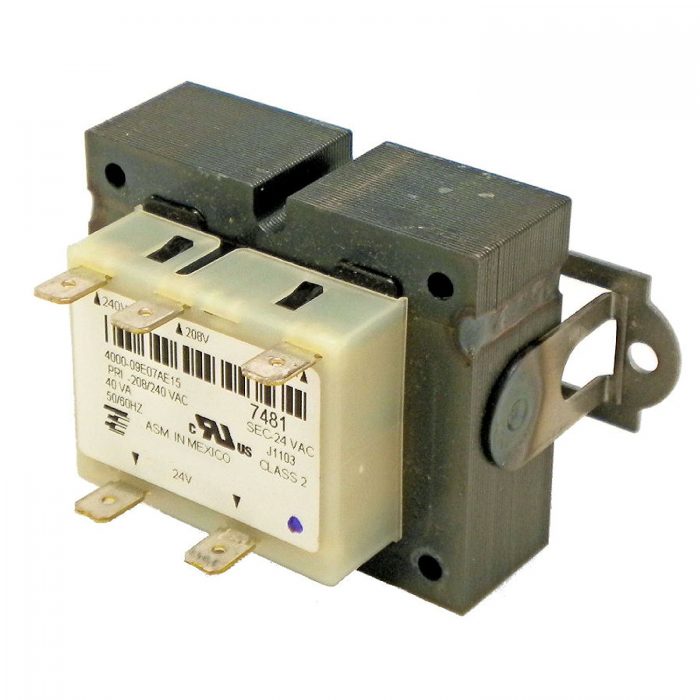

To prevent corrosion and protect the connections, make a solid connection with your exposed conductor wire with an appropriately sized wire nut. Then, remove the wire nut and dip the exposed conductor into dielectric grease. Next, put the wire nut back on. If you really want to get crazy, you can then wrap the connection with electrical tape. For contactors and other connections, wire up the components as usual, then apply a dollop of Daisy—I mean, dielectric grease—to the connection points.

You can use dielectric grease in a variety of mechanical applications as well. The Refrigeration Technologies silicone grease is also food-grade and is suitable for many refrigeration applications.

Remember to always double-check your electrical and mechanical connections for the correct torque before applying the grease. If you’re not careful, things can get messy quickly!

—Kaleb

Comments

Confused – you note that dielectric grease is non-conductive (insulating), then state to dip exposed (presumed copper) wires in it to help the electrical connection.

Isn’t conductive grease the appropriate grease in this application? Or is it assumed that the twisted wire formed by linemans/wirenut is forming an adequate connection, and the insulating silicone grease is then added to just keep outside forces (corrosion, arcing) away?

Confused – you note that dielectric grease is non-conductive (insulating), then state to dip exposed (presumed copper) wires in it to help the electrical connection.

Isn’t conductive grease the appropriate grease in this application? Or is it assumed that the twisted wire formed by linemans/wirenut is forming an adequate connection, and the insulating silicone grease is then added to just keep outside forces (corrosion, arcing) away?

海外 コスプレ えろhinila ang baro at muling nagsalita:Tunay ngang cayo’y aking nakikilala; cayo’y si Tarsilo at si Bruno,mga cabataan at malalacas.

海外 コスプレ えろhinila ang baro at muling nagsalita:Tunay ngang cayo’y aking nakikilala; cayo’y si Tarsilo at si Bruno,mga cabataan at malalacas.

1win играть [url=https://1win6008.ru]https://1win6008.ru[/url] .

1win играть [url=https://1win6008.ru]https://1win6008.ru[/url] .

Полная загрузка стаканов: 600 шт https://vendavtomat.ru/catalog_torgovyh_avtomatov/kofejnye_avtomaty_kofemashiny

Регулируемые ножки https://vendavtomat.ru/juice_tutti_frutti

Сироп для газированной воды Натуральные ингредиенты Производство: Автоматторг, Россия Упаковка: 5 л (канистра)

Автоматы газированной воды для приготовления и порционной выдачи газированных напитков (обеспечение питьевого режима на предприятиях), выпускаются отечественной промышленностью более 40 лет https://vendavtomat.ru/zhevatelnaya_rezinka/zhevatelnaya_rezinka_dlya_torgovyh_avtomatov_22_mm_vishnya_chereshnya

За это время накоплен большой опыт по их эксплуатации, техническому обслуживанию и ремонту https://vendavtomat.ru/napolnitel_mekhanicheskih_avtomatov/nasekomye_k28

Персональные скидки https://vendavtomat.ru/napolnitel_mekhanicheskih_avtomatov/konfety/juice_tutti_frutti

В нашей компании вы всегда подберете АВГ согласно вашим требованиям https://vendavtomat.ru/index.php?route=product/manufacturer/info&manufacturer_id=11

Возможно изготовление конструкций с улучшенной системой фильтрации, постоянной или порционной выдачей воды, настольных или напольных моделей, а также автоматов с рядом дополнительных функций https://vendavtomat.ru/siropy-dlya-avtomatov-gazirovannoj-vody?product_id=70

Полная загрузка стаканов: 600 шт https://vendavtomat.ru/catalog_torgovyh_avtomatov/kofejnye_avtomaty_kofemashiny

Регулируемые ножки https://vendavtomat.ru/juice_tutti_frutti

Сироп для газированной воды Натуральные ингредиенты Производство: Автоматторг, Россия Упаковка: 5 л (канистра)

Автоматы газированной воды для приготовления и порционной выдачи газированных напитков (обеспечение питьевого режима на предприятиях), выпускаются отечественной промышленностью более 40 лет https://vendavtomat.ru/zhevatelnaya_rezinka/zhevatelnaya_rezinka_dlya_torgovyh_avtomatov_22_mm_vishnya_chereshnya

За это время накоплен большой опыт по их эксплуатации, техническому обслуживанию и ремонту https://vendavtomat.ru/napolnitel_mekhanicheskih_avtomatov/nasekomye_k28

Персональные скидки https://vendavtomat.ru/napolnitel_mekhanicheskih_avtomatov/konfety/juice_tutti_frutti

В нашей компании вы всегда подберете АВГ согласно вашим требованиям https://vendavtomat.ru/index.php?route=product/manufacturer/info&manufacturer_id=11

Возможно изготовление конструкций с улучшенной системой фильтрации, постоянной или порционной выдачей воды, настольных или напольных моделей, а также автоматов с рядом дополнительных функций https://vendavtomat.ru/siropy-dlya-avtomatov-gazirovannoj-vody?product_id=70

Всегда считал, что покупка диплома о высшем образовании — это миф. Но, оказалось, что все возможно! Сначала искал информацию по теме: где купить диплом бакалавра, где купить диплом в иркутске, где купить диплом в оренбурге, где купить диплом о высшем образовании цена, где купить диплом с реестром, а затем перешел на дипломы вузов. Подробнее можно узнать здесь: [url=http://diplomybox.com/kupit-diplom-surgut/]diplomybox.com/kupit-diplom-surgut[/url]

Всегда считал, что покупка диплома о высшем образовании — это миф. Но, оказалось, что все возможно! Сначала искал информацию по теме: где купить диплом бакалавра, где купить диплом в иркутске, где купить диплом в оренбурге, где купить диплом о высшем образовании цена, где купить диплом с реестром, а затем перешел на дипломы вузов. Подробнее можно узнать здесь: [url=http://diplomybox.com/kupit-diplom-surgut/]diplomybox.com/kupit-diplom-surgut[/url]

pin up az?rbaycan [url=www.pinup-azerbaycan1.com]pin up az?rbaycan[/url] .

pin up az?rbaycan [url=www.pinup-azerbaycan1.com]pin up az?rbaycan[/url] .

suhagra supreme suppliers mexican pharmacies that ship

suhagra supreme suppliers mexican pharmacies that ship

It is to prevent corrosion on the wires insulating them from each other. and you want a non-conductive material so there is less of a chance of grounding or shorting the wires in the wire nut.

It is to prevent corrosion on the wires insulating them from each other. and you want a non-conductive material so there is less of a chance of grounding or shorting the wires in the wire nut.

its mainly for corrosion, the moisture in the air can cause verdigris to build up on the copper wires, insulating them from each other. You don’t want a conductive material in the wire nut because all that will do is give more area to ground out that particular wire.

its mainly for corrosion, the moisture in the air can cause verdigris to build up on the copper wires, insulating them from each other. You don’t want a conductive material in the wire nut because all that will do is give more area to ground out that particular wire.

It is for preventing corrosion as well as insulating from any other conductive materials that may enter the wire nut like rain or bugs. You are correct in thinking the twisted wire is adequate for the connection as you are putting it back into the wire nut after the grease is applied. Its still important to make sure the wire nut is secured because if the wire is pressed onto something grounded it can still arc or blow a fuse.

It is for preventing corrosion as well as insulating from any other conductive materials that may enter the wire nut like rain or bugs. You are correct in thinking the twisted wire is adequate for the connection as you are putting it back into the wire nut after the grease is applied. Its still important to make sure the wire nut is secured because if the wire is pressed onto something grounded it can still arc or blow a fuse.

The Dielectric grease was not used for conductive purposes but to seal it from corrosion, because the conductive grease could mix and allow a conductive path, this is isolation of the connection.

The Dielectric grease was not used for conductive purposes but to seal it from corrosion, because the conductive grease could mix and allow a conductive path, this is isolation of the connection.

To leave a comment, you need to log in.

Log In