BACK

Should the Float Switch Break R or Y?

Should the Float Switch Break R or Y?

Two Ways to Prevent Freezing in 90%+ Furnace Condensate Lines

Two Ways to Prevent Freezing in 90%+ Furnace Condensate Lines

Condensate Drain Codes & Best Practices

Condensate Drain Codes & Best Practices

Condensate Switch Controversy

Condensate Switch Controversy

Condensate Drainage in a High Efficiency Gas Furnace

Condensate Drainage in a High Efficiency Gas Furnace

Stacking Evaporator Coil Stages

Stacking Evaporator Coil Stages

Condensate Pump Drains

Condensate Pump Drains

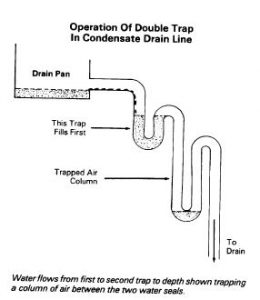

Drains and Double traps

Drains and Double traps

Condensing Furnace Drain Guidance w/ AC Service Tech

Condensing Furnace Drain Guidance w/ AC Service Tech

Water Issues – Spidey Sense

Water Issues – Spidey Sense

#Condensate

Tech Tips:

There are three things we never discuss at the dinner table: religion, politics, and which wire to break with your float switch. A float switch fills with water whenever there is a drain backup, and it breaks power to one of the low-voltage wires. We clearly want the HVAC system to stop producing more condensate, […]

Read more

This tech tip came from an email sent by Adam Blunkall, a Tennessee-based HVAC technician. He shared some tips to help overcome this issue in his market, and we appreciate his insight. Thanks, Adam! If we’re draining our 90% furnaces (or any condensing heating system) outside the structure in a similar fashion as we would […]

Read more

It should be stated and restated that codes and code enforcement vary from location to location within the US. The IMC (International Mechanical Code) is one of the most widely utilized and referenced. The 2015 version of the IMC section 307 is what I will be referring to in this article. Condensate Disposal The code […]

Read more

Condensate overflow prevention devices or float switches, as they are often called, are such simple devices that you wouldn't think there would be much room for controversy. In my experience, there are few areas of the trade where technician and installer preferences and opinions vary greatly. Let's start with some float switch basics. Float (condensate) […]

Read more

This article was written by HVAC/furnace technician Benoît Mongeau. Thank you, Ben. High efficiency (or 90%, or condensing) furnaces use a set of two heat exchangers to retrieve more heat from the combustion products than their mid-efficiency counterparts. Because of this, they generate flue gases much colder than those of a mid-efficiency or […]

Read more

In commercial HVAC, you will find several different types of multi-stage evaporator coils: intertwined (shown above), horizontal face split (one coil on top of another), and vertical (side by side). When staging a horizontal evaporator, pay attention to ensure that stage #1 is on the bottom and stage #2 is on the top. If stage […]

Read more

One of my techs (Jim Walch) brought another common “double trap”-style issue to my attention: techs and installers running a drain too far into a condensate pump. When you run the system drain too deep into the pump reservoir, the water level can rise high enough to cover the drain end. That can create the […]

Read more

Double traps are no good. That's the end of this tech tip. Okay, here's some detail: Anytime your drain goes up and down more than once, you have a double trap UNLESS you place an air vent between the two traps that vents ABOVE the drain inlet. The double trap causes drainage issues because air […]

Read morePodcasts:

Bryan and Craig Migliaccio (AC Service Tech)dive deep into the complexities of managing condensate drainage in high-efficiency (90%+) gas furnaces. The conversation begins with a clear explanation of why these furnaces produce condensate in the first place – they have two heat exchangers that extract so much heat from the combustion gases that water […]

Read more

This episode of the HVAC School podcast dives deep into the often-overlooked but critical topic of water issues in HVAC systems. Bryan and Bert discuss the various causes of water leaks and condensation problems, and they explain how to prevent them. They emphasize that water damage is not an inevitable part of HVAC systems […]

Read more