BACK

Piston Design and Bypass

Piston Design and Bypass

How to Set a Charge by Superheat

How to Set a Charge by Superheat

Piston vs. TXV Metering Devices

Piston vs. TXV Metering Devices

Replacing a Piston w/ TXV and Evacuation

Replacing a Piston w/ TXV and Evacuation

#piston

Tech Tips:

I remember it like it was yesterday. It was my first day of work as a trainee at my first technician job, just a wet-behind-the-ears kid fresh out of trade school. It was a Monday morning, and the technicians and I were standing in the dusty warehouse surrounded by stacks and stacks of brand new […]

Read more

So many techs are OBSESSED with how to set the charge rather than understanding all of the readings, specs, and system conditions that go into optimum system performance. Before “setting the charge,” I suggest (nay, I REQUIRE) that you do a full visual inspection of the system, have an understanding of the initial factory charge […]

Read more

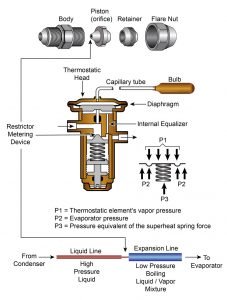

The piston (fixed orifice) and TXV (thermostatic expansion valve) are the two most common metering devices in use today, though some modern systems utilize an electronically-controlled metering device called an EEV (electronic expansion valve). It should be noted that there are other types of fixed-orifice metering devices, like capillary tubes; however, their use is not […]

Read more

We get a lot of questions about both evacuation procedure and TXVs so last week we produced videos on both topics, including: • Before and after testing of piston vs. TXV • Using the Bluvac Measurequick app • Use of core remover tools for evacuation • Flowing nitrogen • creating an external equalizer port and […]

Read more