BACK

Impacts of Decreasing Evaporator Airflow

Impacts of Decreasing Evaporator Airflow

TD of Refrigeration Evaporators

TD of Refrigeration Evaporators

Some Important Terms to Know

Some Important Terms to Know

Hydronics GPM Calculation and More…

Hydronics GPM Calculation and More…

#td

Tech Tips:

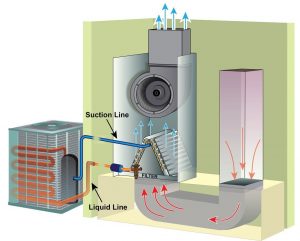

Airflow, airflow, airflow… When we set up and commission comfort cooling and heating systems, we need to pay more attention to airflow before worrying about the fancy controls or the refrigerant circuit. One way to do that is by checking out Bill Spohn's Airflow 101 webinar on ESCO Group's learning network, which you can access […]

Read more

We have discussed DTD (design temperature difference) quite a bit for air conditioning applications, but what about refrigeration? Let's start by defining our terms again. Suction Saturation Temperature The saturation temperature is the temperature at which the refrigerant will be at a given pressure if it is currently changing state. This change of state would […]

Read more

In my recent classes with my employees at Kalos, we've been going over finding target pressures and temperatures for an air conditioning system. The goal has been to get techs to have “target” readings in mind before they start connecting tools. This step is an important part of being able to “check a system without […]

Read more

This tech tip was written by a friend of HVAC School, Brian Mahoney. He is an HVAC instructor at Western Suffolk BOCES/Wilson Tech. Thanks, Brian! The podcast on delta T for A/C the other day got me thinking about the formula I learned in school about calculating the GPM of a hydronic system. We will […]

Read more