July 2018

This article is part 4 of a 5-part series on troubleshooting by Senior Refrigeration and HVAC tech Jeremy Smith Ok, so we've got our data scribbled and scratched out on paper. Maybe a bit of grease, dirt, and oil, too, if you're doing things right—blood if you're doing it wrong. Now, time to take a […]

Read more

This article is part 3 in a 5-part series by Senior Refrigeration and HVAC Technician Jeremy Smith. Let's start with step#1 in the flowchart: Gather data. This is why we spend money on those fancy digital manifolds, shiny electrical meters, and other gadgets, widgets, and doodads. It isn't to brag about them on Facebook; it's […]

Read more

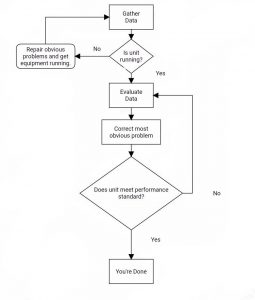

This article is the second in a 5-part series by Senior Refrigeration and HVAC tech Jeremy Smith. The Ground rules I've spent some time thinking about troubleshooting and the processes and procedures that I use to find problems. Not the “why isn't my air-conditioner running?” problems, but the “Things just aren't quite right”-type problems—the really […]

Read more

This article was written by Senior Refrigeration tech Jeremy Smith. Big thanks to Jeremy for his contributions to HVAC School and the tech community. Having spent many years in the trade and many years reading posts from techs on forums and social media, a big issue that I see is that troubleshooting is something of […]

Read more

A conversation about the pros and cons of commercial vs. residential with Andrew Greaves from AK HVAC on Youtube

Read more

Cleaning ductless systems is critical… and a pain.. Rather than just telling you how we do it let me show you some of the key points. This video demonstrates cleaning and testing a ductless system including pulling the blower wheel and washing the evaporator with a bib kit. I also wrote a process for […]

Read more

Three things done in an HVAC/R condenser and what it means

Read more

As a technician gains skill, they will learn that regularly testing your tools is a huge part of success. It isn't long in the field before techs find out that just because a meter or gauge gives a particular reading, it doesn't ALWAYS mean it is correct. Vacuum is one of these areas. Everything in […]

Read more

As a technician gains skill they will learn that regularly testing your tools is a huge part of success. It isn't long in the field before techs find out that just because a meter or gauge gives a particular reading it doesn't ALWAYS mean it is correct. Vacuum is one of these areas. Everything in an […]

Read more