March 2020

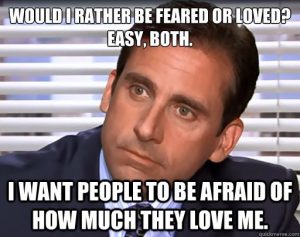

As a leader, it’s healthy to take a step back and see if you’ve become “That Boss.” You know, the one who nobody wants to work for and who doesn't have a shred of self-awareness. I worked at a large corporation for 5+ years, and it was easy to tell which managers valued employees. It […]

Read more

Everyone in the HVAC/R trade uses some type of torch to braze or solder alloys together. So, what is the proper way to handle an oxyacetylene torch? It turns out that there’s more than one right answer. Depending on which torch rig you use, the manufacturer’s manuals for operation may vary. Everyone (hopefully) knows […]

Read more