BACK

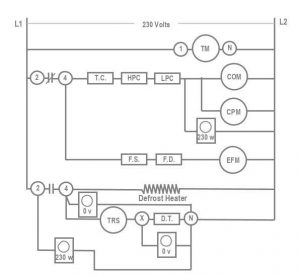

Isolation Diagnosis

Isolation Diagnosis

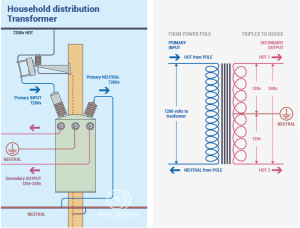

Understanding 240-Volt Circuits

Understanding 240-Volt Circuits

Beware of “Ghost” Voltage

Beware of “Ghost” Voltage

#electrical diagnosis

Tech Tips:

There are many great diagnostic tools available to the service technician today, but I haven't found a tool as versatile as the simple isolation diagnosis. There are many ways this concept can be applied, but let's start with some examples so that you get what I mean. Low Voltage Short Circuit Isolation Diagnosis You arrive […]

Read more

It can be useful to think of a multimeter as a “voltage drop” tool. Bryan covers the concept here in an excellent class that I highly recommend. This concept was a big help to me as I began to truly learn how to use a multimeter. A meter reads the voltage differential between two points. […]

Read more

Disclaimer: “Ghost voltage” is a term used by techs to explain a phenomenon where they measure voltage they don't expect or when the voltage they see doesn't do the work they expect. More advanced techs know how to use the Lo-Z (low impedance) mode on their voltmeter if it has one to help eliminate this. […]

Read more