BACK

It’s All Relative… Humidity

It’s All Relative… Humidity

Not All CFM Are Created Equal

Not All CFM Are Created Equal

Equipment Sizing and Airflow in Different Markets

Equipment Sizing and Airflow in Different Markets

Improving Humidity Control on the Cheap

Improving Humidity Control on the Cheap

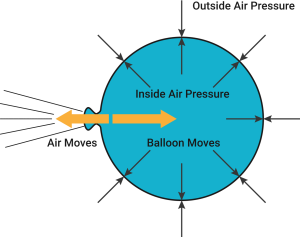

Does Mass or Volume Move Heat?

Does Mass or Volume Move Heat?

The Impact of Adding or Removing Water From Air

The Impact of Adding or Removing Water From Air

How to Reduce Indoor Humidity

How to Reduce Indoor Humidity

Understand Dew Point and Absolute Moisture, The Right Side of the Psych Chart

Understand Dew Point and Absolute Moisture, The Right Side of the Psych Chart

Room Sensible Heat & CFM – Advanced Psychrometrics Part 1

Room Sensible Heat & CFM – Advanced Psychrometrics Part 1

ERVs – What You Need To Know w/ Dr. Bailes

ERVs – What You Need To Know w/ Dr. Bailes

Santa Fe Talks Dehumidification at AHR 2025

Santa Fe Talks Dehumidification at AHR 2025

Q&A – Condensating Vents – Short #208

Q&A – Condensating Vents – Short #208

#humidity

Tech Tips:

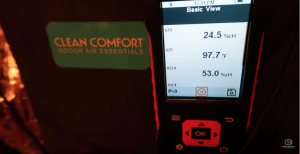

Florida’s got a lot of great qualities: some pretty neat wildlife, beaches all around, and theme parks. On the flip side, Florida also has hurricanes and a lot of humidity. As much of a pain as it might be for residents and contractors alike, humidity is one of my favorite topics. We see relative humidity […]

Read more

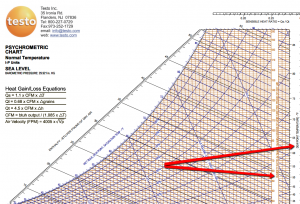

We’re in the business of moving heat, but we have to move air to accomplish that. We use CFM (cubic feet per minute) to quantify the air we move over the indoor coil, and it helps to imagine hundreds of 1’x1’x1’ boxes of air moving over that coil each minute. (After all, 400 CFM is […]

Read more

This tech tip was heavily informed by Ed Janowiak’s past symposium presentations. You can watch his presentation about setting proper airflow HERE. You can also now purchase your tickets for the 6th Annual HVACR Training Symposium HERE. HVAC School was founded by a Floridian—representing Climate Zone 2, to be exact. So, it’s no surprise that […]

Read more

This tech tip was submitted by Steve Rogers, the current president of The Energy Conservatory (TEC). Steve has been on the podcast several times in the past and is a valued contributor to HVAC School. Thanks, Steve! As summer approaches, HVAC technicians all over the US are preparing for those difficult conversations with occupants about […]

Read more

I once heard someone say, and have since repeated many times that BTU's ride on the back of Cubic Feet of Air or CFM. As I've learned more I've come to the conclusion that the weight or mass of the air passing over the evaporator coil is far more important to understand both in terms […]

Read more

Air conditioning was about humidity control from the very start. Willis Carrier's very first air conditioning system was all about controlling the humidity with the side effect that it also could reduce the sensible temperature. Theaters caught on that this newfangled contraption could lead to big summer numbers when they installed it to keep patrons […]

Read more

Sometimes I beat around the bush too much in these tech tips, so let's get down to the nitty-gritty! (As Nacho Libre would say.) Humidity inside a home should be maintained between 30% and 60% relative humidity. I like to shoot for 50% in humid climates when possible (and by possible, I mean financially feasible […]

Read more

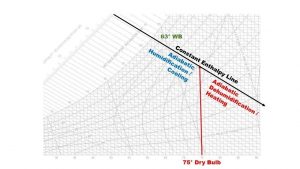

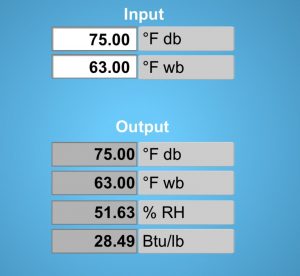

Let's first state the obvious. Most techs are intimidated by psychrometric charts and Mollier diagrams. We JUST ARE. While there are some pretty complicated formulas that back up these diagrams, using them isn't that big of a deal once you understand the different elements and then focus on one at a time. BUT WHY DO YOU […]

Read more

This is the first of a three-part series of articles that will dive deep into advanced psychrometrics. The source material for each of these articles may be found in ACCA Manual P Sections 3, 4, and 5. This article is based on information found in Section 3. Psychrometrics is the study of the physical and […]

Read moreVideos:

Podcasts:

In this episode of the HVAC School podcast, host Bryan sits down with building science expert Allison Bailes to dive deep into the world of Energy Recovery Ventilators (ERVs). The conversation explores the critical role of ventilation in modern homes, highlighting how ERVs have become an essential component of maintaining indoor air quality and […]

Read more

In this insightful discussion at AHR 2025 in Orlando, Bryan connects with Nikki Krueger from Santa Fe dehumidifiers, exploring the evolution and importance of whole-house dehumidification in modern HVAC systems. Nikki, who has spent 20 years in the indoor air quality industry, shares her journey from a public relations background to becoming deeply involved […]

Read more

In this short Q&A podcast episode, Bryan answers Kenton's question about how to stop vents from condensating, especially when sealing and insulation don't do the trick. When approaching a condensation problem, we have to consider the source of moisture and where the condensation is happening. Moisture that builds up on top of the vent […]

Read more