BACK

Motor Speed – The Basics

Motor Speed – The Basics

Watts So Confusing?

Watts So Confusing?

HP, Motor HP, BHP, Motor Watts

HP, Motor HP, BHP, Motor Watts

Motor Types

Motor Types

Motor Ambient Rating – Short #241

Motor Ambient Rating – Short #241

What Is Up With Blower Amps & Watts w/ Steve Rogers

What Is Up With Blower Amps & Watts w/ Steve Rogers

High Voltage A/C Electrical Class

High Voltage A/C Electrical Class

The Value of First Time Completion of PSC Motor Failures With Universal ECM

The Value of First Time Completion of PSC Motor Failures With Universal ECM

#motors

Tech Tips:

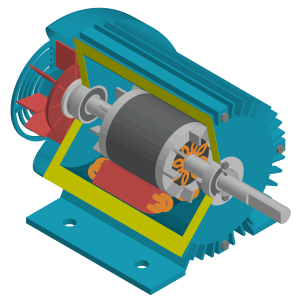

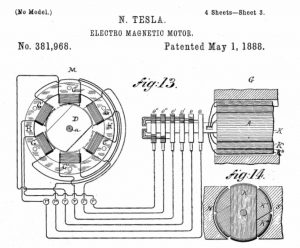

How does a typical single phase motor know how fast to run? Typical induction motors are dependent of the electrical cycle rate of the entering power (measured in hertz) for their speed. Our power in the US makes one complete rotation from positive electrical peak to positive peak 60 times per second or 60hz (50hz […]

Read more

Most motors are designed to a set amount of work, usually rated in either watts or horsepower (746 watts per HP). Watt's law states that watts = volts x amps. If a particular motor needs to do 1 horsepower of work at 120 volts, it will draw about 6.22 amps. And yes, in an inductive […]

Read more

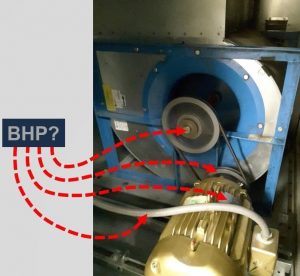

Brake horsepower (BHP), motor nameplate HP, and the actual electrical power (watts) a motor will consume are different but related concepts. They can get confusing. So, we will tackle them one at a time. Let us start with simple definitions of work, power, and horsepower. Work = distance in feet x force in pounds, both […]

Read more

In residential and light commercial HVAC, we work primarily with PSC (permanent split capacitor) motors. However, it is good to be aware of some other types. PSC (Permanent Split Capacitor) A common medium torque single phase motor with a run capacitor always in the circuit. This type makes up the majority of HVAC motors (condenser […]

Read moreVideos:

Podcasts:

In this short podcast episode, Bryan talks about what the ambient rating means on a motor. These ratings can be found on both condensing fan motors and blower motors. They have Cs in their rating, which represents the maximum ambient temperature the motor can handle in degrees Celsius (like 40C or 60C). Heat and […]

Read more

Bryan Orr and Steve Rogers dive deep into measuring power consumption in HVAC blower motors, particularly focusing on the differences between PSC (Permanent Split Capacitor) and ECM (Electronically Commutated Motor) technologies. The discussion stems from a question raised at an educators' conference about the accuracy of clamp-on meters in measuring blower motor watt draw, […]

Read more

This podcast is a high voltage A/C electrical class that Bryan gave to some of the Kalos apprentices. The high voltage journey begins with basic electrical theory. Basically, a difference in charge is needed for electrons to move and generate power. Motors, which are inductive loads, are the greatest users of power that we will […]

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more