BACK

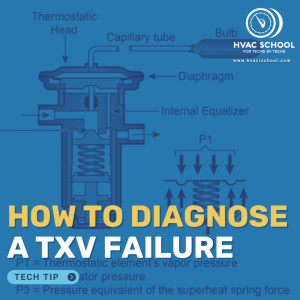

How to Diagnose a TXV Failure

How to Diagnose a TXV Failure

What is a HSO (Non-Bleed) TXV/TEV?

What is a HSO (Non-Bleed) TXV/TEV?

Why and How to Adjust a TXV/TEV

Why and How to Adjust a TXV/TEV

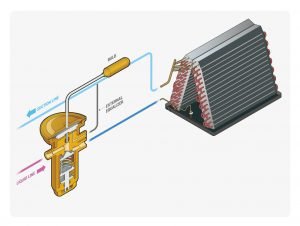

TXV Bulb Placement

TXV Bulb Placement

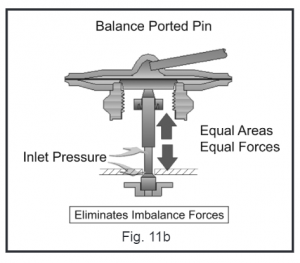

Balanced Port TXV

Balanced Port TXV

How a TXV Works and Why I Call it a CSV

How a TXV Works and Why I Call it a CSV

The 5 Readings Every Tech Must Know Well

The 5 Readings Every Tech Must Know Well

Demystifying TEVs

Demystifying TEVs

#TEV

Tech Tips:

There has been much written and many jokes made about the misdiagnosis of TXV (thermostatic expansion valves), and rightly so. This article will cut straight to the point to help those of you who may still need a bit of clarification, and hopefully, we will save the lives of a few TXVs and the pocketbooks […]

Read more

There is a lot of misunderstanding about the HSO (hard shut-off) or “non-bleed” TXV (thermostat expansion valve) and what makes it shut off, why it exists, and how it “magically” opens. Once you understand the forces inside the valve, it is quite simple, obvious, and sadly devoid of any magic. The Three Forces The TXV […]

Read more

As we discussed in an earlier podcast, a TXV maintains a specified and constant superheat at the evaporator coil outlet. It does this through a balance of forces between the bulb pressure (opening force), equalizer pressure (closing force), and spring pressure (closing force). We can actually adjust the spring pressure on some valves. But why […]

Read more

When mounting a TXV bulb or checking bulb placement, there are a few important considerations (listed in order of importance): Mount the bulb on the suction line. Flapping in the breeze is no good. Mount it TIGHTLY with a proper metallic strap (usually copper, brass, or stainless steel)—not with zip ties or tape. Position it on […]

Read more

I walked into a supply house the other day and looked at a “universal” expansion valve on the shelf. The friendly guy behind the counter saw me and walked over. After saying hello, he said: “That's a great valve; it's even balanced port.” Now, I am a bit of a troublemaker. I should have […]

Read morePodcasts:

In this episode of HVAC School, Bryan talks to Leslie about the deceptive TXV. Thermostatic expansion valves, also known as TXVs or TEVs, are metering devices that maintain superheat. They contain an external equalizer. External equalizers give the pressure reading that you would normally take with a suction gauge at the end of the evaporator […]

Read more

In this episode of HVAC School, Bryan covers the “5 pillars of refrigerant circuit diagnosis” and why they matter. They are: Superheat Subcool Suction pressure Head pressure Air temp split (delta T) These 5 readings give you a holistic idea of the A/C system. Instead of getting hooked on checking only superheat and subcool […]

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more