BACK

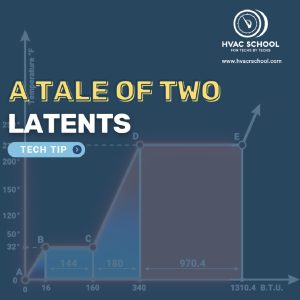

A Tale of Two Latents

A Tale of Two Latents

Equipment Sizing and Airflow in Different Markets

Equipment Sizing and Airflow in Different Markets

How to Reduce Indoor Humidity

How to Reduce Indoor Humidity

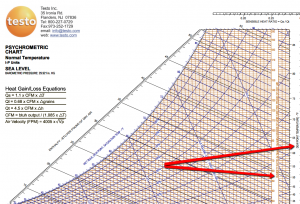

Understand Dew Point and Absolute Moisture, The Right Side of the Psych Chart

Understand Dew Point and Absolute Moisture, The Right Side of the Psych Chart

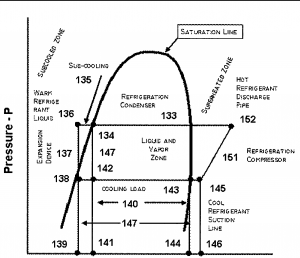

What is the “Mid Point” of a Refrigerant Blend?

What is the “Mid Point” of a Refrigerant Blend?

Room Sensible Heat & CFM – Advanced Psychrometrics Part 1

Room Sensible Heat & CFM – Advanced Psychrometrics Part 1

What Willis Understood

What Willis Understood

What Is Temperature Glide?

What Is Temperature Glide?

Santa Fe Talks Dehumidification at AHR 2025

Santa Fe Talks Dehumidification at AHR 2025

Q&A – Condensating Vents – Short #208

Q&A – Condensating Vents – Short #208

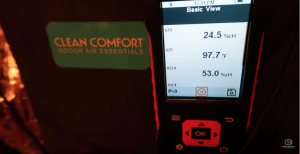

Q&A – Testing Dehumidifiers – Short #206

Q&A – Testing Dehumidifiers – Short #206

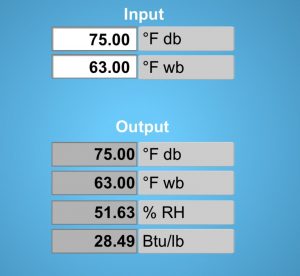

Psychrometrics Basics w/ Jamie Kitchen Podcast

Psychrometrics Basics w/ Jamie Kitchen Podcast

Psychrometrics Without Tears

Psychrometrics Without Tears

#dew point

Tech Tips:

When the quiz or the teacher asks what “latent” heat is, there is generally some reference to it being hidden heat, which is what the word “latent” means. We then learn that it is heat energy transferred that results in a change of state rather than a temperature change. Later on, we hear a lot […]

Read more

This tech tip was heavily informed by Ed Janowiak’s past symposium presentations. You can watch his presentation about setting proper airflow HERE. You can also now purchase your tickets for the 6th Annual HVACR Training Symposium HERE. HVAC School was founded by a Floridian—representing Climate Zone 2, to be exact. So, it’s no surprise that […]

Read more

Sometimes I beat around the bush too much in these tech tips, so let's get down to the nitty-gritty! (As Nacho Libre would say.) Humidity inside a home should be maintained between 30% and 60% relative humidity. I like to shoot for 50% in humid climates when possible (and by possible, I mean financially feasible […]

Read more

Let's first state the obvious. Most techs are intimidated by psychrometric charts and Mollier diagrams. We JUST ARE. While there are some pretty complicated formulas that back up these diagrams, using them isn't that big of a deal once you understand the different elements and then focus on one at a time. BUT WHY DO YOU […]

Read more

As we have mentioned in several previous articles (such as this one HERE), many blended refrigerants have glide, which simply means they boil and condense over a range of temperatures instead of just one temperature. As an example, consider refrigerant R407c. It is a zeotropic blend, which means it has enough glide to make a […]

Read more

This is the first of a three-part series of articles that will dive deep into advanced psychrometrics. The source material for each of these articles may be found in ACCA Manual P Sections 3, 4, and 5. This article is based on information found in Section 3. Psychrometrics is the study of the physical and […]

Read more

I've been reading a book called Cool: How Air Conditioning Changed Everything, and it got me interested once again in the history of air conditioning and refrigeration. Like many things, the people who are credited with “inventing” are the ones dogged enough to make an idea commercially successful, not the idealists forever tucked away in the […]

Read more

We've all heard about glide, but what is it really, and how does it affect our system? Glide, or temperature glide, is the difference between the bubble point and the dew point of the zeotropic refrigerant mixture. Well, that wasn't very helpful, was it? All we did was introduce new terms without defining them, […]

Read moreVideos:

Podcasts:

In this insightful discussion at AHR 2025 in Orlando, Bryan connects with Nikki Krueger from Santa Fe dehumidifiers, exploring the evolution and importance of whole-house dehumidification in modern HVAC systems. Nikki, who has spent 20 years in the indoor air quality industry, shares her journey from a public relations background to becoming deeply involved […]

Read more

In this short Q&A podcast episode, Bryan answers Kenton's question about how to stop vents from condensating, especially when sealing and insulation don't do the trick. When approaching a condensation problem, we have to consider the source of moisture and where the condensation is happening. Moisture that builds up on top of the vent […]

Read more

In this short podcast episode of the Q&A series, Bryan answers a question about testing dehumidifiers (submitted by Steven via Speakpipe). Dehumidifiers run air over a cold evaporator coil (to pull moisture out of the air and drain it out) and then reheat it over a condenser coil. The air leaving a dehumidifier is of […]

Read more

In this episode of the podcast, Jamie Kitchen from Danfoss talks about wet-bulb, dry-bulb, relative humidity, dew point, enthalpy, and latent heat. These are the building blocks of psychrometrics, which deals with human comfort as it relates to temperature, humidity, and heat loads. Humidity is water vapor in the air. As the air's dry-bulb temperature […]

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more