BACK

What You Know About Start Winding Inrush Current Might Be Wrong

What You Know About Start Winding Inrush Current Might Be Wrong

Start Capacitor and Inrush Facts & Myths – Part #2

Start Capacitor and Inrush Facts & Myths – Part #2

Start Capacitor & Inrush Facts and Myths – Part #1

Start Capacitor & Inrush Facts and Myths – Part #1

#start winding

Tech Tips:

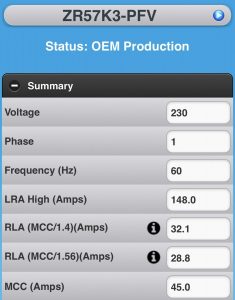

Take a look at the specs from this Copeland scroll compressor pulled from the Copeland Mobile App (which is an incredible app, by the way). These specs are for a single-phase compressor, so the amperages listed are based on an amperage reading from the wire connected to the common terminal. LRA is the locked rotor […]

Read more

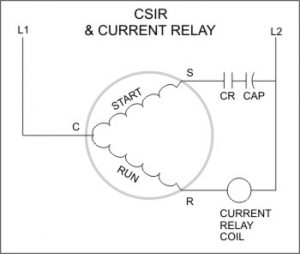

Thought Experiment #3 – The Start Winding Has No “Inrush” with a run capacitor only The name “start winding” is an antiquated term for the single-phase residential industry. It came from the days when CSIR (capacitor start, induction run) motors were still used commonly. In a CSIR motor, the start relay removes the start winding […]

Read more

This series of articles is one of those that will bug a lot of people because it will go against a lot of what you've been told about compressors, start capacitors, and inrush current. For that reason, I want you to work through a few thought experiments first and maybe even stop and try it […]

Read more