BACK

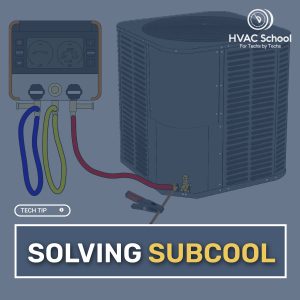

Solving Subcool

Solving Subcool

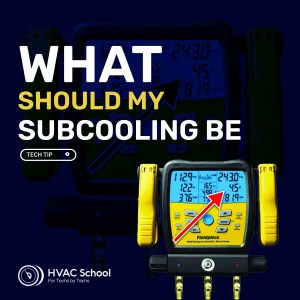

What Should My Subcooling Be?

What Should My Subcooling Be?

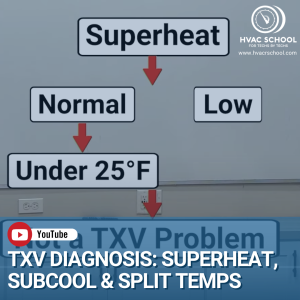

Negative Superheat? Time to Check Your Tools

Negative Superheat? Time to Check Your Tools

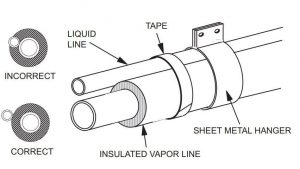

Subcool and Liquid Line Length

Subcool and Liquid Line Length

The Case for Checking the Charge Without Using Gauges

The Case for Checking the Charge Without Using Gauges

Q&A – How to Learn Superheat & Subcooling – Short #191

Q&A – How to Learn Superheat & Subcooling – Short #191

#subcooling

Tech Tips:

I teamed up with Ty Branaman to design an intuitive way for techs to solve some of the “what should it be?” questions in the HVAC field. The topic for this sheet is subcooling. Subcooling is a measurement of the temperature DECREASE of a liquid below its saturation (mixed liquid/vapor) temperature at a given pressure. […]

Read more

This is the article you read BEFORE you call and ask a senior tech what your subcooling should be. It's also the one you send to a junior tech when they call and ask you: So, what is subcooling? (Or subcool, as many call it.) Subcooling is a measurement of the temperature DECREASE of a […]

Read more

I was fresh out of school, working as an apprentice at my first real HVAC job, and I was listening in on a shop conversation between a few techs. They were talking about finding so many overcharged systems. One of the techs turns to me and says, “I had a unit yesterday that was so […]

Read more

The primary role of setting an appropriate level of subcooling is to ensure that we deliver a full line of liquid refrigerant to the metering device. We want to do this at: A pressure differential required by the metering device At a temperature and pressure no higher than required for maximum capacity and efficiency But […]

Read more

Jim Bergmann and I recorded a podcast for HVAC School that covered when and how to check the refrigerant circuit without connecting gauges. Listener Joe Reinhard listened several times and wrote up this summary of what he gained from the episode. I edited it lightly, but most of this is his work. Thank you so […]

Read moreVideos:

Podcasts:

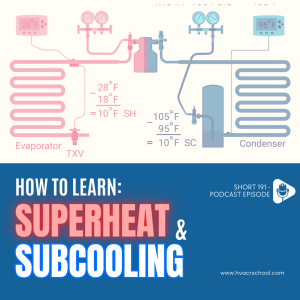

In this short podcast episode, Bryan answers an audience member's question and explains how to learn superheat & subcooling, two fundamental aspects of the HVAC/R trade. You can submit questions of your own at https://www.speakpipe.com/hvacschool. Saturation is when a substance is in the liquid and vapor state in the same place. Eugene Silberstein likes to […]

Read more